Thank you guys. Its nice to know someone out there is looking!

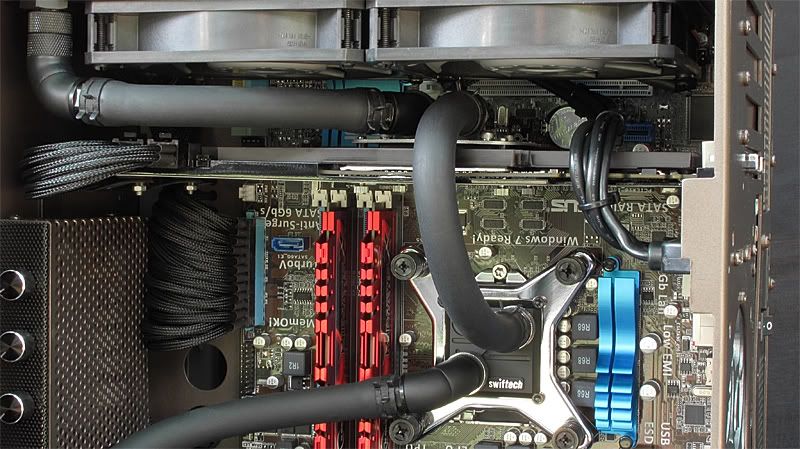

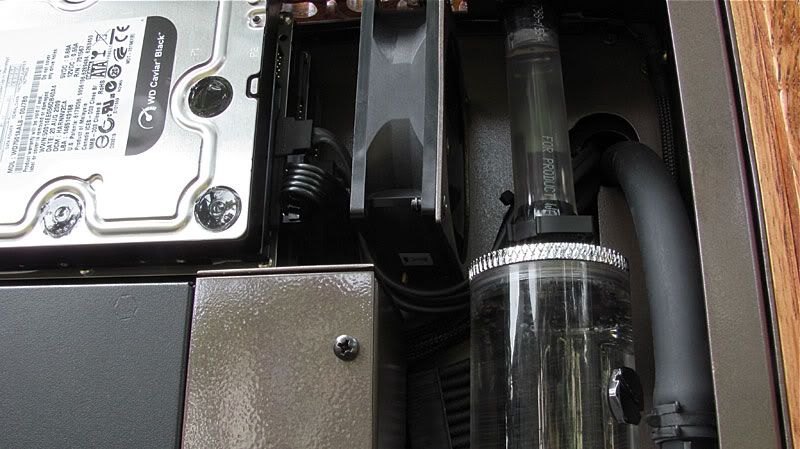

That idea already is lurking in the back of my mind. I'm not sure however how hard it will be to sand and polish copper tubing to get it looking good. It would have to be sanded to remove the ink stamping on the tubing. The other problem is that with the case as compact as it is, I am almost certainly going to have to solder in a few elbows. I don't see being able to just bend the tubing enough to make it fit. I don't think the solder joints would look very good.

Reply With Quote

Reply With Quote

Bookmarks