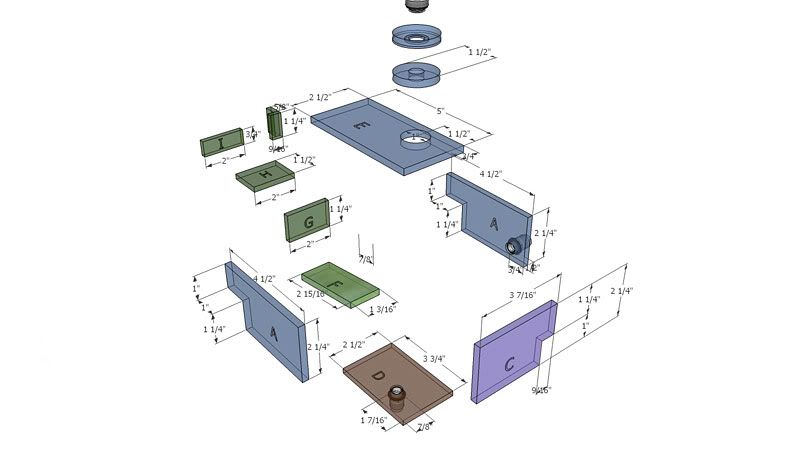

Making the Reservoir

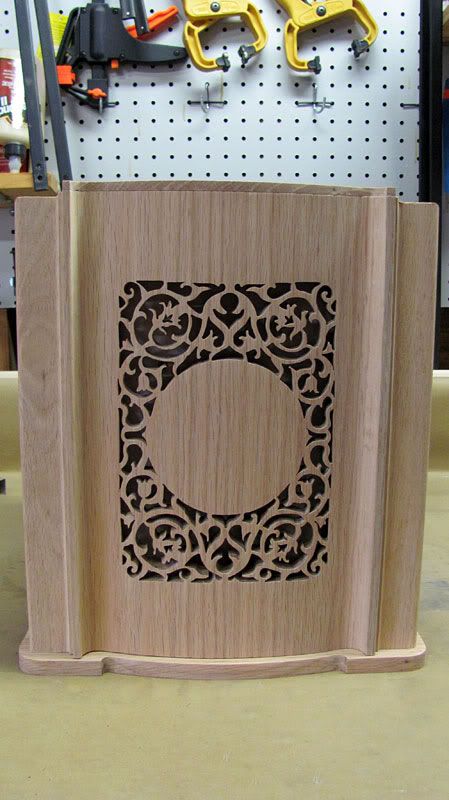

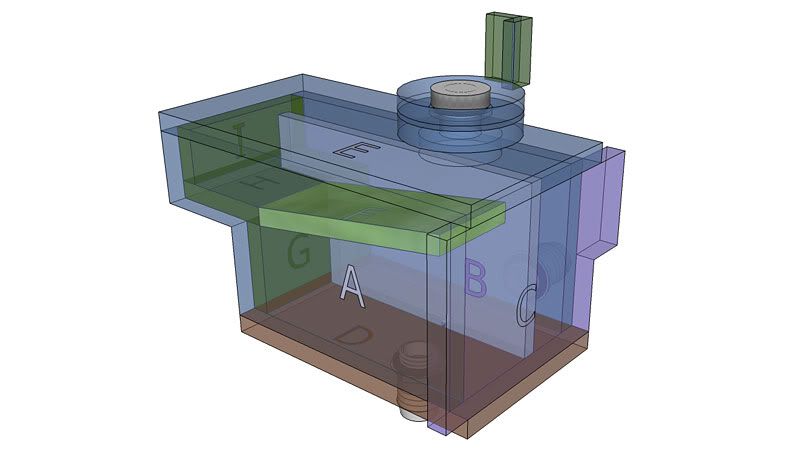

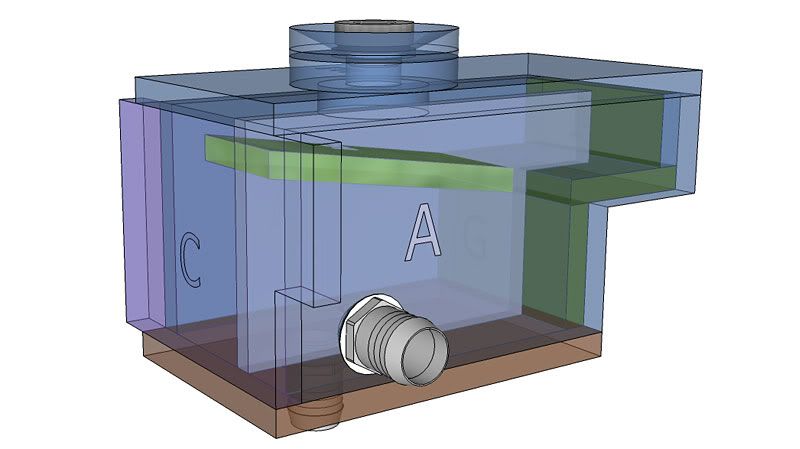

Part of making custom cases with watercooling is that you run into situations where out-of-the-box reservoirs simply may not fit or work well. I personally do not like T-lines, and so stick with reservoirs. I designed this build to continue using my Aquastream XT Ultra, which has necessitated that I come up with a custom reservoir that will fit the case. I also find that being able to customize my own reservoirs allows me to route the loop how I want, not how a reservoir may dictate due to its limited options. That being said, making a cylindrical reservoir is far easier than making a rectangular one.

Tips for Making a Rectangular Acrylic Reservoir

I am by no means some kind of expert at working with acrylic, and there are others that do a lot more with acrylic than I ever hope to. I do however have some things I can share that I've figured out via trial and error that have helped me.

1. The type and thickness of acrylic are important for reservoirs. I would not even attempt this using extruded acrylic. Extruded acrylic is far too soft to machine well, and crazes far too easily (crazing is cracking that occurs when acrylic is stressed too much). I only use 1/4 cast acrylic. Cast acrylic is much harder, and machines very similarly to wood.

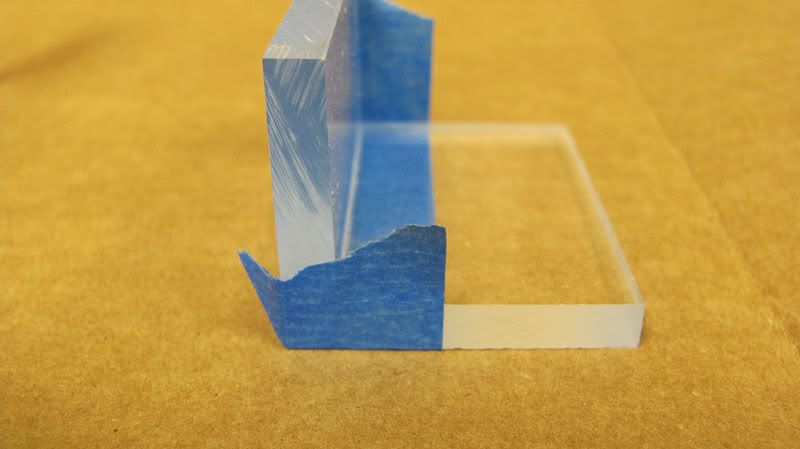

2. A rectangular reservoir requires very precise, smooth cuts in order for the joints to weld properly. The ultimate here would be to have access to a laser cutter. Acrylic pieces cut with a laser are perfectly dimensioned, and have perfectly smooth, clean edges. I have a very good table saw with an aluminum/acrylic hollow ground blade. This blade makes very clean cuts that are smooth enough to solvent weld without any sanding. You can also cut pieces with a simple hand held miter box. Trying to use plywood saw blades on a table or miter saw scratches up the acrylic edges too much requiring sanding. It is hard to sand edges and not get them out of square.

3. When it comes to sanding edges, I do not machine sand any edge that I'm going to solvent weld. Sanding heats up acrylic a lot, and if edges that are machine sanded are later solvent welded, they tend to craze. I only hand sand any edges I have to, including any exterior edges that are not directly being welded.

4. Weld-on #3, or Tap Plastics solvent (basically the same thing) are my weapons of choice. This solvent is like water, but when used, produces very strong joints.

5. Smooth, accurate edges produce strong, tight solvent welds.

6. Plan your reservoir around making mistakes. I know that anything I cut with my table saw is going to be very accurate, so any rectangular piece is going to be spot on. With this reservoir however, I had to cut a piece out of the rectangular sides to form a kind of L shape. I therefore made the L shaped sides as the outside most pieces so that if the part I cut out is a bit off, it doesn't matter.

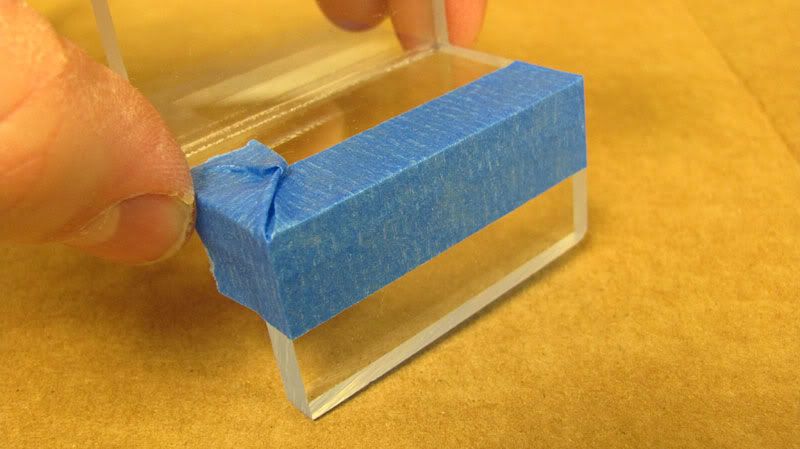

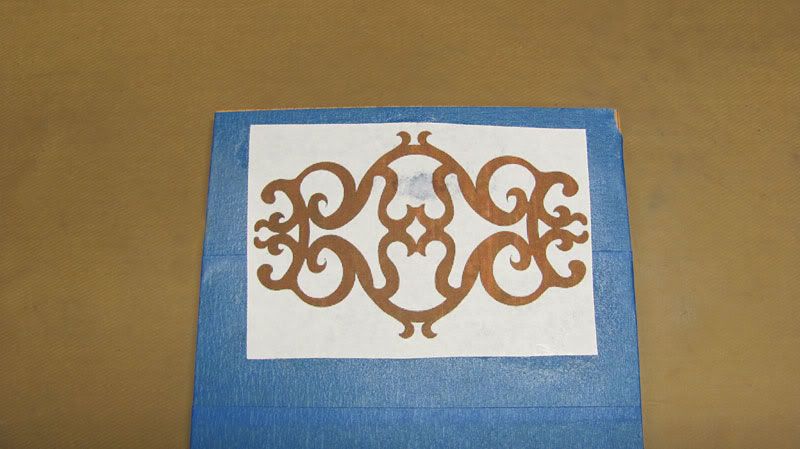

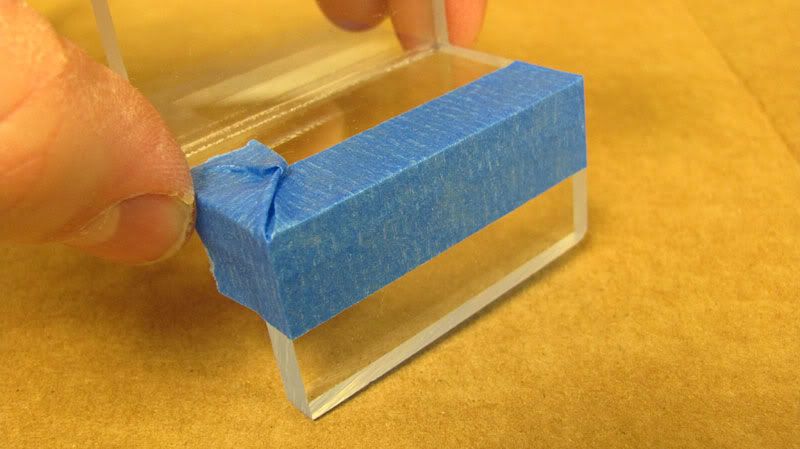

7. When solvent welding joints, I use 3M painter's tape to hold the joints together. Don't use cheap tape here. The painter's tape holds the joint just the way you want, and it also keeps the solvent from running out of the joint.

8. You can use a tap and make G1/4 threaded holes for use with metal fittings. I'm using a G1/4 plug for the top of the res. This works OK as long as the metal fittings aren't tightened too much. Over-tightening will cause crazing in the acrylic. I prefer however to use plastic barbs/fittings as they put very little stress on the acrylic. I used 3/8NPT threaded black plastic barbs sealed with silicone for this res.

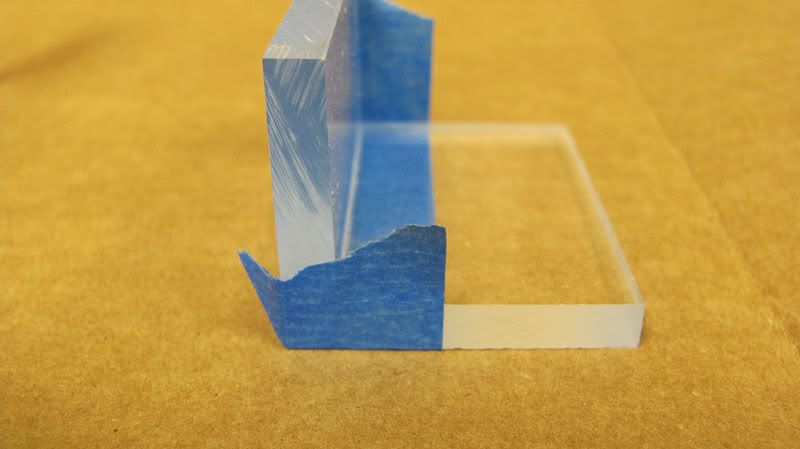

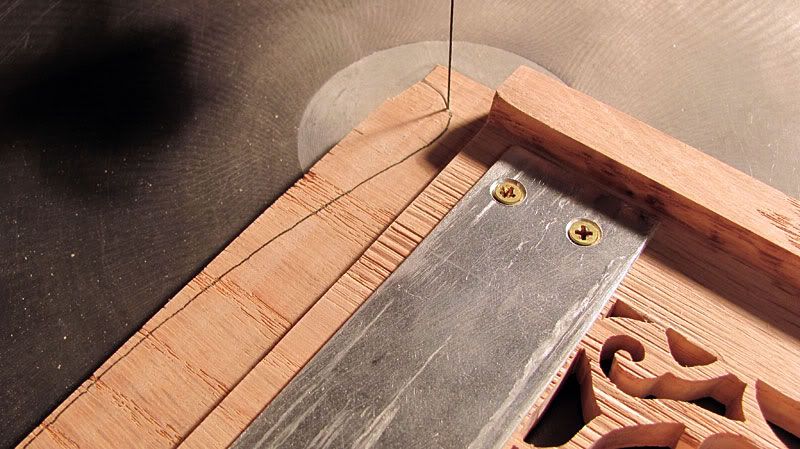

With all of this said, on to the pics. I of course first cut out all of my pieces on my table saw. I used my scroll saw with the rpms turned down slow to cut out the sides into their L shape.

Before I put any pieces together, I drilled the necessary holes and tapped the threads I needed. This is a lot easier to do before you start putting pieces together. The shavings can also find their way into corners of the res where you don't want them if you tap the threads after putting together the res. I usually use silicone spray to lubricate the tap for acrylic.

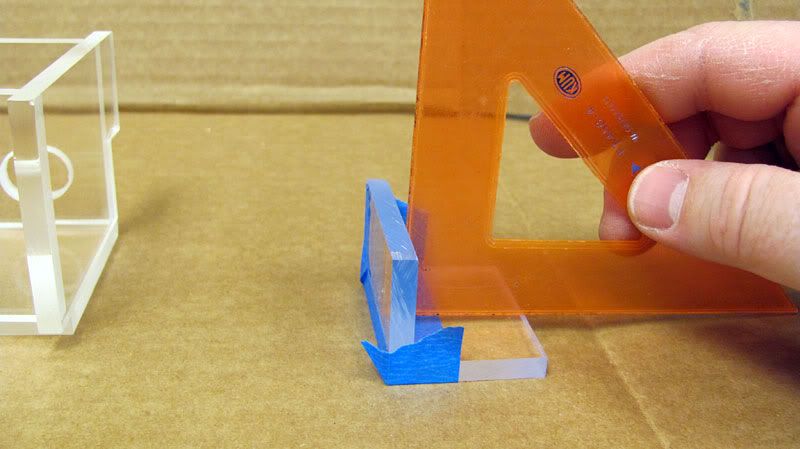

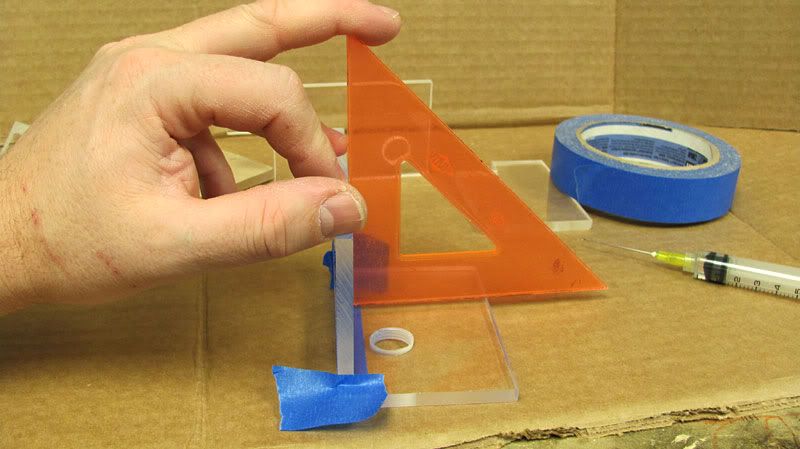

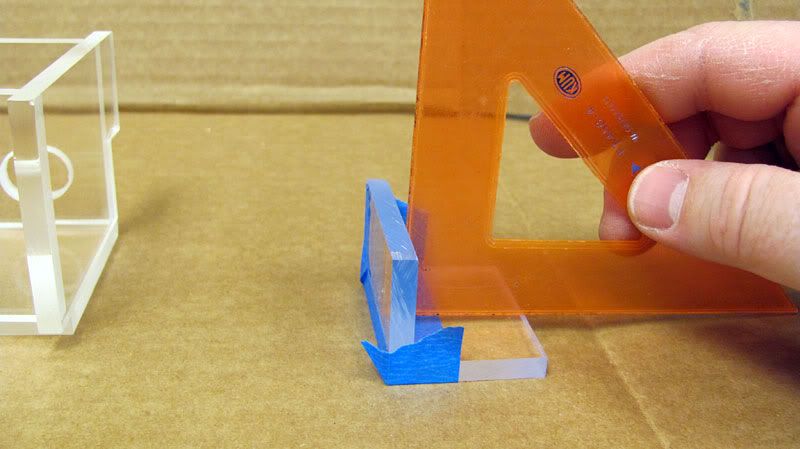

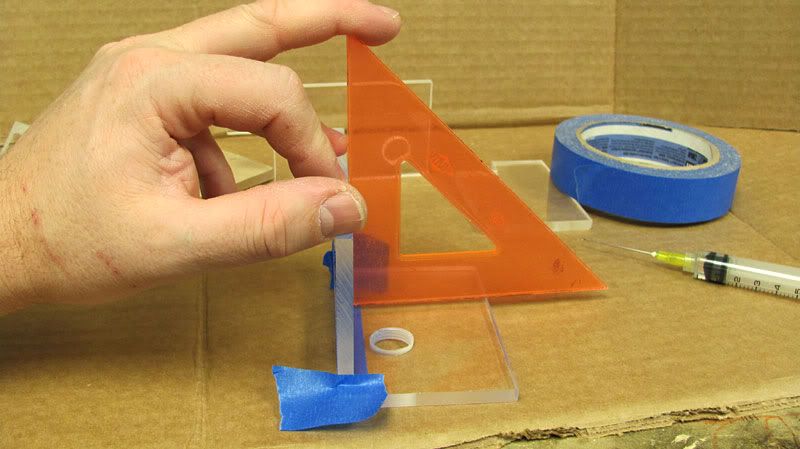

Using a triangle square, I started solvent welding the pieces together.

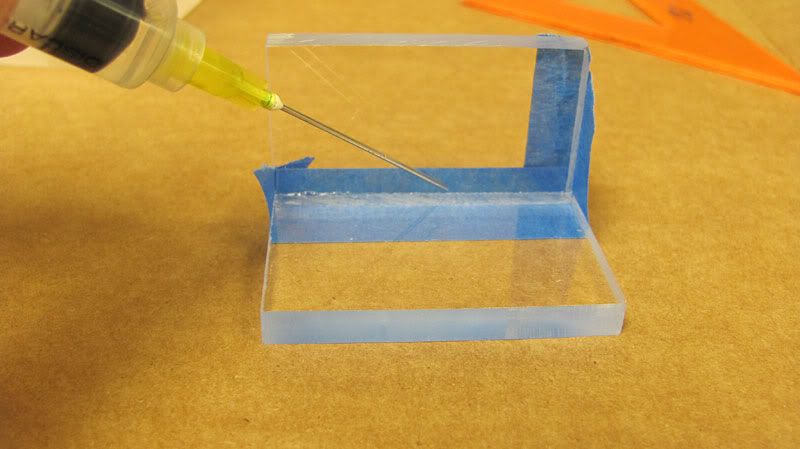

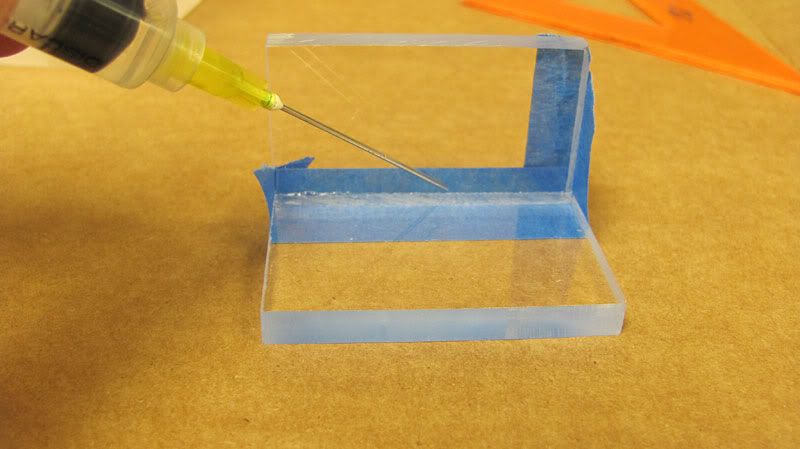

The method of joining I am using here is called capillary solvent welding. This is yielding me some very smooth, strong joints. The little bit of bubbling you see is nothing to be concerned about. I like the 1/4 thickness of the acrylic as it is far more forgiving of minor flaws than say 1/8 would be.

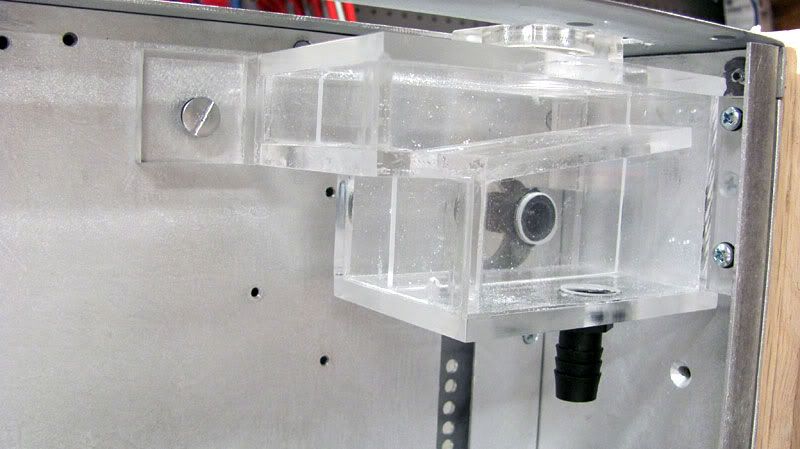

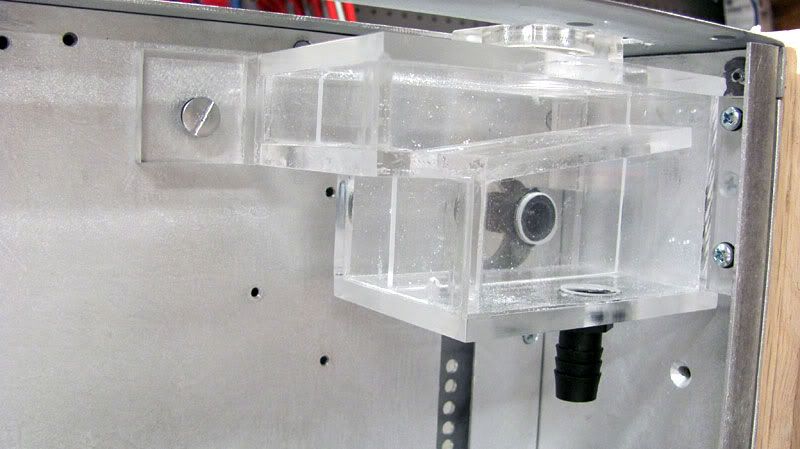

Here is a shot with everything but the front and top on. I decided to glue the top on and then the front as this afforded me the easiest way to get solvent into the joints using the barb holes.

After everything was together, I clamped the res. This helps eliminate any air bubbles in the joints. You want to stick to clamping down the edges, and not clamping down too tightly. You don't want to tighten the clamps like a gorilla, particularly away from the edge, and craze the acrylic.

Here is the res mounted. I still need to clean it out in case you are wondering. Note that I'm using o-rings and a rubber washer on the mounting screws where they touch the acrylic to make sure I don't craze the acrylic. The two side screws go through the metal front into the wooden corner.

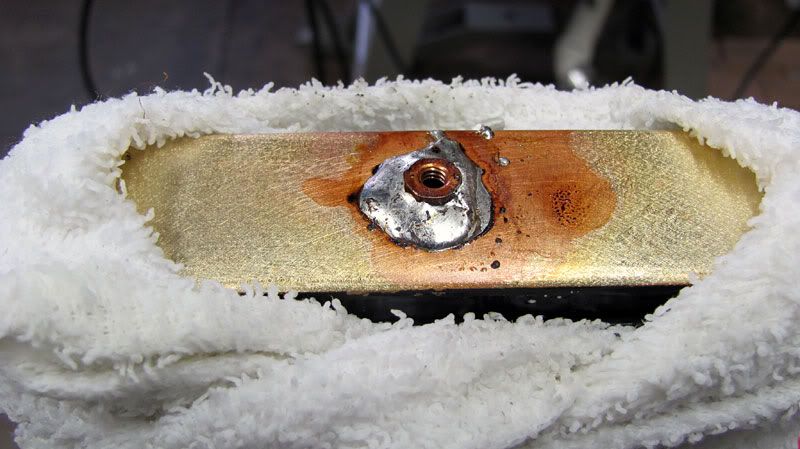

For the part of the res that is mounted to the PSU panel, instead of using a metal screw which doesn't hold that tightly in 16 gauge alu, I used this insert to go through both panels.

I am going to leaktest the res with air pressure to make sure everything is tight.

USB Port

I use a USB hub for everything, but I do like having at least one port that is plugged directly into the MB. I bought a panel mount USB cable. I made a little rectangular metal mounting piece for the port. I cut out the hole using a jig saw. I then used wood chisels to chisel out the recess for the USB mount.

I've been pondering whether I'm going to stick with my Aquastream XT, or buy a new MCP35x. The Aquastream is a very quiet pump, which is why I bought it, but the MCP35x is quite a bit smaller, and with the new PWM, the rpm is temp adjustable which should make it very quiet as well. I'm still chewing on this. If I do switch to an MCP35x, I may also make a different res, this time out of some 2 copper tubing (-decisions, decisions...).

Thanks for stopping by.

Reply With Quote

Reply With Quote )

)

.

.

I always get a twinge of nervous expectation when I see this thread has new posts.

I always get a twinge of nervous expectation when I see this thread has new posts.

Bookmarks