excellent work, simply amazing cutting skills.

excellent work, simply amazing cutting skills.

Cooler Master Haf X

i5 3750k

Asrock Xtreme 4

660 Ti

I love the look of of bare aluminum too, but look at the pic below with all those fine scratches.

The panels were fine until I started cleaning them with paper towels, I now only use micro-fibre cloths.

If I could find a way to remove all the fine scratch marks i would consider leaving it bare.

Thanks for your comments everyone.

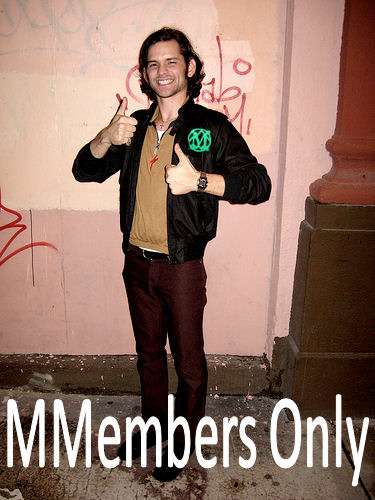

This kicks butt!!! I would like to extend an honorary membership to teh MM fan klub since you clearly enjoy the same athetics and design as the rest of us . . .and were able make it your own in grand fashion!!!

You deserve two thumbs up!!!!

Yah, the 4'x8' panel I got has a ton of scratches. Think yours looks pretty prestine compared to that, but I got it for free so hard to complain

You can try brushing the aluminum, looks pretty easy

http://forums.bit-tech.net/showthread.php?t=114028

although the edge will come out a bit more stand-out looking.

If you want your case air-brushed I bet Smooth Creations could do a knockup job!

"Thing is, I no longer consider you a member but, rather a parasite...one that should be expunged."

This case is very nice. The attention to detail is excellent. You have done a very good job in this. Having built my own case, I can appreciate the time and attention it takes to make something like this. It sounds however that like me you are a perfectionist. While everyone else looks at how nice the case is, you notice every little flaw that you incurred while building that everyone else doesn't even see.

Last edited by voigts; 09-21-2008 at 01:40 AM.

Latest Project Log: Project Quintessence

1935 Zenith Radio Scratch Build

Your very observant, perfectionist most of the time but i do appreciate how well the case came out in the end.

I haven't heard of Smooth Creations, maybe they can smooth over the scratches.LoL

What's the secret password to teh MM fan klub? LoL

No i haven't tried rubbing compound, what kind did you use and what's involved.

Here's more pictures

That's all for now guys.

Thanks for your input.

www.smoothcreations.com

They painted this which you will love

http://www.ncix.com/products/index.p...moothcreations

"Thing is, I no longer consider you a member but, rather a parasite...one that should be expunged."

Nice case!

I just noticed that you live in Ontario. Perhaps you could come up with a little something...

Originally Posted by inCore

hi zuess, i used the turtlewax premium rubbing compound

it's just like using brasso/metal polish.

just put a generous amount of the rubbing compound on a damp cloth and rub in a circular pattern on the area you want to remove the scratches.

i suggest you try on some other bare metal first before your pc to see the effect.

That's fantastic painting, I looked at Smooth Creations website.

Would cost me a small fortune for shipping to Oregon though.

Just cut em and make it exactly the way you want. Easier to do then making a caseBuy a connector kit, some extra pass through molex, pin remover tools, heat shrink, heat gun for $20 at home depot /lighter and probably some other stuff I am forgetting. Lot less clutter and I think improves the internal look of a computer a ton.

Planning on bending some HDD fan brackets as well and looks like you put enough space on yours to turn the HDD around and have the cabling be more hidden. Provided the holes line up going the other way. If not, maybe slot the whole thing.

Last edited by Herc130; 09-25-2008 at 07:45 AM.

EXCELLENT WORK....You should make some and sell them I think they would go really fast

Thanks for your input.

I have all kinds of equipment that you mention, I dont use a heat gun though I use a jeweller's mini butane torch.

I have all the radiator fans wired together.

What I need to buy are the 6pin connectors that plug-in to the PSU, then I can keep the original psu cables stock just in case I ever want to sell it.

Yes your right, if I turn the hdd's around so the connections are closer to the fans the bracket screw holes don't line up.

Making new hdd brackets to turn the drive so to hide the cables better is still another project for my case.

Thanks very much,

Well if anyone is in need for a panel or a bracket that they can't find just send me a PM, remember I'm in southern Ontario though.

Zuess, Great workmanship and attention to detail. I have been looking very closely at your build. I'm currently building a work area for a mad cap project I've been thinking about for nearly 2 years. It involves building a similar frame except my dimensions would be W537 x D575 x H810 mm, to hold 2 horizontally positioned motherboards each with its own WC system.

You and others are probably thinking "it's simple, just build the frame and fill in all the bits", if only it were that simple. It's a mod of a well known production single mobo tower case , and I want to keep as much of the original trim and look as possible, but the design is proving to be a real headache. Think of it as being a square peg round hole issue.

I keep looking at your project to inspire me to keep going until I find a solution for my design.

Keep up the good work, looking forward to your next update.

Hi interDOS, I see what you mean it's to bad you couldn't just stretch the front panel width to double it.

Don't give up, cuz in the end it will look great and be so easy to work with.

Good Luck.

It's been awhile since I have updating my build log, but I recently started

making custom lenght cables and sleeving them.

The first thing I had to figure out was how to make the sleeving and

heat shrink all the same length.

Here's the T-Square I have had forever.

I used one of the sata power cables that came with the Antec TruePower Quattro psu, as well as another cable I had that had some 90 degree

connectors.

It's got six connectors, and right now I only have 3 hdd's but I will be

anding 3 more in the future.

Next up will be the 24pin power cable

Bookmarks