I'm currently wrapping up some changes on my setup, and I thought I would share a trick which proved very useful that I recently picked up here on XS. I can't find the thread now, but the idea is one of the handiest I've come across in years of watercooling. It was only mentioned in a thread, but there isn't an entire thread about it. I used this several times in redoing the lower part of my loop, and it works great. Not only can it save you from having to use elbows and such, but it can help you avoid having situations where the tubing is pressing against barbs and wanting to kink due to tight bends.

If you want to form tubing for tight bends or any bends, you can shape it the way you want. You simply make sure it somehow it is in a steady position in that shape, and then immerse it in boiling water and then in ice water several times and it will form how you like. I found a spring for $3 at a local ACE hardware that fits perfectly inside of the 7/16” id tubing. A spring is necessary in order to make sure the tubing doesn't kink while forming. In the mention of this idea I originally saw, the guy used a rope, but a rope would leave marks on the tubing whereas a spring doesn't.

I am using XSPC 7/16" id 5/8" od tubing in my setup. For the loop in the pic above, I put the tubing into a plastic Tupperware cup, immersed it in boiling water for a minute or two, then ice water, and repeated the process a few times. Obviously if you use a cup or the like, it needs to be able to handle boiling water. It would probably be easier to use a jar like a pickle jar since the tubing did have a tendency to want to work its way out of the cup due to the taper.

Once heated and cooled like this a few times, the tubing holds it shape.

I have a very tight spot where one radiator feeds the other radiator. The space measured from the outside (not the inside) between the barbs is only 2 1/4” (about 57mm). The inside space between the barbs is only about 1 1/4”. Tubing would normally kink in a bend this tight. Since the piece of tubing was very short, and the bend had to be so tight, I simply used a pair of tongs to hold the tubing while forming. Using tongs did leave a small indentation on the tubing, but it is no big deal.

The tubing formed so that just sitting the outside was only 3” apart. I had no kinking problems putting it at 2 1/4” apart.

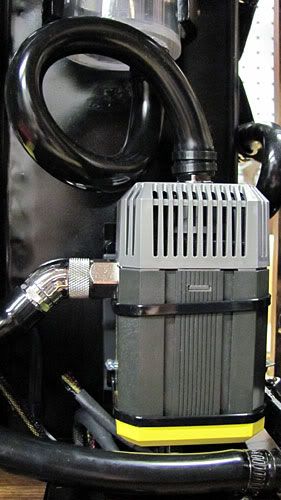

I also used this on my pump to GPU connection so that the tubing wouldn't be pushing against the pump.

Maybe this will be a help to others as well.

Reply With Quote

Reply With Quote .

.

....

....

*

*

Bookmarks