Main rig:

CPU: I7 920C0 @ 3.6Ghz (180*20)

Mobo: DFI UT X58 T3eH8

RAM: 12GB OCZ DDR3-1600 Platinum

GPU/LCD: GeForce GTX280 + GeForce 8600GTS (Quad LCDs)

Intel X25-M G2 80GB, 12TB storage

PSU/Case: Corsair AX850, Silverstone TJ07

Owl's 6002 images he asked me to post while he is at work

Oh yeah baby

This is the pressure test with TIM. As you can see it isn't properly spread yet, but hey, it looks pretty nice so far

And again, does anyone have a sample or two left? I've ran out

Main rig:

CPU: I7 920C0 @ 3.6Ghz (180*20)

Mobo: DFI UT X58 T3eH8

RAM: 12GB OCZ DDR3-1600 Platinum

GPU/LCD: GeForce GTX280 + GeForce 8600GTS (Quad LCDs)

Intel X25-M G2 80GB, 12TB storage

PSU/Case: Corsair AX850, Silverstone TJ07

@Martijn , so you applied TIM on the IHS then the two sheets?

------------------------------------------------------------------------------------------------------

Crunch with us, the XS WCG team

------------------------------------------------------------------------------------------------------

Main rig:

CPU: I7 920C0 @ 3.6Ghz (180*20)

Mobo: DFI UT X58 T3eH8

RAM: 12GB OCZ DDR3-1600 Platinum

GPU/LCD: GeForce GTX280 + GeForce 8600GTS (Quad LCDs)

Intel X25-M G2 80GB, 12TB storage

PSU/Case: Corsair AX850, Silverstone TJ07

Martin do not send that sample back right now I am on dry testing only. On a second round I would like to target areas of interest and a wet test will probably be one of them.

I have four forums and 60 samples so I kind of have my hands full - one thing at at a time.I am getting older and can not juggle too many things in my head as I used to, I gotta do things systematically to keep track of things

It's a little early yet to draw any conclusions But Bail_w and Littleowl's 6002 with the best contact patterns are the one's that saw the greatest gains with ICD7 over their previously installed grease while the low contacts one saw the least.

Since contact and pressure are closely related here it is hard to pull out which has the most influence here. I know that between the min and max PSI is worth a couple of degrees however I do not know how much or if pressure will increase contact/performance across that range yet.

Thanks Tasty! I went down a good bit but I didn't see it on the spread sheet.

so I have one question that maybe you or someone else can answer.

What pressure should we be looking at to say that our block is putting such and such pressure??

PSI = Force/area

so for the 6002 62.3/1.29 = 48.3 psi

the "tail' on 6002 may have influenced the result one way or another.

The linescan and histogram shows a longer and broader contact pressure with about a minimum of 40psi near where the core would be.

The pseudocolor shows an area of 50 to 77lbs running diagonally near the center much better than the fuzion by a large margin

The fuzion was near the lower threshold of the paper 28psi in the same area

Last edited by tastymannatees; 04-25-2008 at 12:44 PM.

Main rig:

CPU: I7 920C0 @ 3.6Ghz (180*20)

Mobo: DFI UT X58 T3eH8

RAM: 12GB OCZ DDR3-1600 Platinum

GPU/LCD: GeForce GTX280 + GeForce 8600GTS (Quad LCDs)

Intel X25-M G2 80GB, 12TB storage

PSU/Case: Corsair AX850, Silverstone TJ07

Littleowl - Looking at post 411 the core temps have a pretty wide spread. as mentioned earlier I wonder if this could be used as an indicator of contact quality?

That could be some of my fault.I had changed chip to a G0

I didn't know they were that much different in temps and all when I did it. I just know the G0 was supposed to be a better clocker. I am sorry.

When I get the package from you I plan on kind of starting over with my E6600

it is running with D7 right now out in my barn. I plan to date the cure time and do all the pressure stuff all again with that chip.right now it is on a stock fan.

i'll also be testing with a lapped heatsink (TR ultima 90) and ihs (x2 4200) when i get my film and have time.

XS WCG Rules: #1: don't pull fart_plume's finger #2: Dave aka Movieman, don't give him your phone number if you like your hearing

XS WCG Note: There are 2 sets of points, WCG and Boinc. WCG = 7x Boinc

Project: Dark Matter (<- link) - Asus Maximus II Formula, Intel X3330 3.4ghz @1.32v under load, corsair ddr2 1066 8gigs, evga gtx260 core 216, pc p&c 750W, EK Supreme HF Nickel, iandh 175 res, Swiftech MCP355, Black Ice GTX G2 240, Lian Li v1200b

silverstone tj07 build log

Here are my first set of thermal and pressure results with more before the weekend is out.

This first riund of testing was done my Q6600 G0 at 3600 with 1.43v. Cooling is a Rev. 1 Swiftech Storm with a drilled out ThermalRight bolt-thru kit backplate. The MX2 and the first ICD7 results used the stock springs compressed almost all the way and the second ICD7 test was a "Hard mount" or no springs just wing nuts all the way down. I have tried everything I know to get the temps on the different cores to even out but 3 and 4 just refuse. I have come to the conclusion that the difference is due to poor contact/ spreading of the solder that connects the cores and the IHS.

All ambient temps were measured with a UEI DT200 + K-Type probe

All core temps were measured with RealTemp 2.24 with no Idle calibration with is why most Idle temps are below ambient.

Original MX2 ~2 Months cure time

Ambient: 23.1

Idle: 23, 25, 20, 20

Load: 41, 41, 35, 37

Mount Pictures

ICD7 with springs ~1 day cure time

Ambient: 23.2

Idle: 21, 23, 20, 20

Load:40, 40, 35, 37

Mount Pictures

Pressure test

ICD7 Hardmount ~1 day cure time

Ambient: 22.8

Idle: 21, 20, 21, 20

Load: 38, 39, 34, 34

Mount Pictures

Conclusions/ Observations

ICD7 consistently beats MX2 in my tests and from the early numbers on my E6600 it is beating ASC by a good margin also. I did notice a 1-2 degree drop in temps after a few hours with I assume is due to the thickness of the paste and the time it needs to spread. I was rather suprised by the pressure test, I had guessed that it would be relatively even because of the fairly even distribution of paste but apparently the top and bottom of the CPU are higher. Also, I found it interesting that I got the best temps on the mount with the least of the IHS covered. This could be a result of the design of the storm, which concentrates almost all of the cooling area of the block directly over the cores creating little benefit to contact outside of the cooling "patch".

I will add Thermal results from my E6600 and X2 5000+ BE later today or tomorrow.

time to compare my results

AS5 - ambient of 25C

WCG 100% load temps

core 1: 35

core 2: 40

Shin Etsu X23 - ambient of 22C

idle temps:

core 1: 29C

core 2: 34C

WCG 100% load

core 1: 36C

core 2: 41C

IC D7 - 22C ambient

idle

core 1:25-26

core 2:32-34

WCG load

core 1:34-36C

core 2:40-42C

AS5 seems to win by a hair for load but since i forgot to get idle temps for it i'm not sure if the AS5 won on idle. imo, the D7 matched the Shin Etsu for load and the D7 won on idle. I think that my cpu being a 65W model is holding back the D7.

XS WCG Rules: #1: don't pull fart_plume's finger #2: Dave aka Movieman, don't give him your phone number if you like your hearing

XS WCG Note: There are 2 sets of points, WCG and Boinc. WCG = 7x Boinc

Project: Dark Matter (<- link) - Asus Maximus II Formula, Intel X3330 3.4ghz @1.32v under load, corsair ddr2 1066 8gigs, evga gtx260 core 216, pc p&c 750W, EK Supreme HF Nickel, iandh 175 res, Swiftech MCP355, Black Ice GTX G2 240, Lian Li v1200b

silverstone tj07 build log

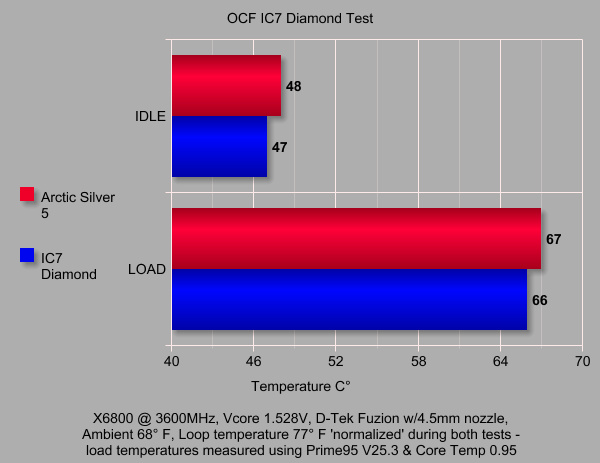

Did this awhile back for OCF.

Another Fuzion block interesting

Update:

04/27/08

10:54am

Ambient = 22.6c

Cure time would be one week (24x7, no cycling) @ 5:45pm today

Idle:

Core 0: 35

Core 1: 35

Core 2: 33

Core 3: 33

Load:

Core 0: 46

Core 1: 46

Core 2: 47

Core 3: 46

Last edited by SiGfever; 04-27-2008 at 07:37 AM.

XSWCG Disclaimer:

We are not responsible for the large sums of money that you WILL want to spend to upgrade and add additional equipment. This is an addiction and the forum takes no responsibility morally or financially for the equipment and therapy cost. Thank you and have a great day.

Sigmund Freud said... "Failure to CRUNCH is a sign of Sexual Inadequacies".

Looking at the contact prints I do not see any startling revelations, you performance guys have been lapping the IHS's for awhile although to me the contact results over pressure was to an large extent a little surprising.

The contact paste Impressions have been talking all along and I have not been listening. The center print on the impression bob123 took will probably come in at the Max press. range of the film.

If you look at the paste the IHS picture on center it looks to be at the best BLT possible, probably probably close to the bulk loaded particle size. the depressions surrounding it are some thousandths of an inch deep, multiples of an optimum BLT which will flatten the numbers a bit and looks to be linked to those showing equal to or marginal improvements having to transfer the heat through Some % of a thicker medium. This enough to knock a couple of degrees off the test result

Looking at a number of paste impressions we have been seeing a good qty have a thick impression of compound. 90% of my testing is on a synthetic die so every application looks like the optimum center circle with just a haze or glaze of compound. Intel's spec on pressure is 43 psi +/- 10lbs. required to flatten the IHS.

The thicker impressions of paste I have been seeing I assumed to be due to insufficient pressure to flatten the IHS and spread the grease. Obviously from the initial prints this is not true. Intel falls way short on this little fact, it is not happening.

So I am probably wrong on the pressure front I think for 75% +/- of the not significantly improved results however Most look tied to contact issues. We will have to look at the final test results to draw a final conclusion but this looks like the way it is trending.I think on the whole we will end up with just a few contact patterns that will cover the range something like concave ( I have one IHS at overclockers with just the edges only) convex, concave/convex and biases one side or the other, ripple with several highs and lows.

From the results it's starting to look to be mostly mechanical for the marginal result group, I see no problems with software or electronics so far.

Anybody else have a opinion or idea on this?

Your bottom diagram is exactly the profile I've seen when I have lapped core 2 quads. An island in the middle surrounded by a "moat". And I agree that the paste pattern has agreed with the pressure film all along. I had noted this in the results from the original post that this CPU seems to have the "usual" profile and might benefit from lapping.

Your hypothesis sounds right. When I've tried really cranking down water blocks, it doesn't seem to squash down the IHS with any amount of pressure. Only lapping improved the overall contact. (This is from observations on my main rig, a QX6700. This machine I put through the ringer to get the best temps I could.)

What I will try on this is the method you suggested of just taking off the edges. I always thought that dead flat was the way to go, but maybe your idea would work better.

I'll try to get to it today. We've had a break in the weather here so yard work has taken temporary priority....

Regards,

Bob

EDIT: Andrew, if you want the high res pictures of anything I've posted, let me know and I can email them. I resize them all to 9 inches wide for posting here. The normal res I shoot at would be 31 inches wide posted here...

my ihs and heatsink had ripples just like that before i lapped them. can't wait to get that pressure film and see what happens.

XS WCG Rules: #1: don't pull fart_plume's finger #2: Dave aka Movieman, don't give him your phone number if you like your hearing

XS WCG Note: There are 2 sets of points, WCG and Boinc. WCG = 7x Boinc

Project: Dark Matter (<- link) - Asus Maximus II Formula, Intel X3330 3.4ghz @1.32v under load, corsair ddr2 1066 8gigs, evga gtx260 core 216, pc p&c 750W, EK Supreme HF Nickel, iandh 175 res, Swiftech MCP355, Black Ice GTX G2 240, Lian Li v1200b

silverstone tj07 build log

A high res of the Center Glaze would be great. The BLT there is probably only .001 thick. If you all want to send me your CPU's I run a dial indicator check on them, I promise to send them back.

I wonder if it is possible to to take an impression on a piece of fine metal foil. Then take on indicator reading off of that. compressed state vs relaxed

Yes you did say that from the beginning about the contact and I was not listening. I was looking at the trees, not the forest. Great observation on your part. Thick headed on mine.

Last edited by tastymannatees; 04-27-2008 at 09:40 AM.

Bookmarks