-

Comp Desk Layout Changes, Pump Changes, Lighting Fix

Changing My Computer Setup

I just started again making some changes and finally completely finishing my case. I was most of the way there, but had a few things I wanted to fix before putting up pics, and I decided to make a few changes as well. Also, the Xclio 200mm fan that I had bought for the side panel quit working, and they don't reply to emails and have no place on their website for an RMA, so I need to replace the side fan.

About 2 months ago, I decided to change the way that my computer space is set up. My wife likes this computer so much that she suggested putting in outside of the desk so that it is more visible. I have found that having the computer inside of the computer desk compartment is a royal pain when it comes to wiring. The wiring behind and under my desk going to/from my computer and stuff was a dusty mess of spaghetti, and was laying all over the carpet behind the desk. Trying to make any changes was a royal pain. Our desk is an oak rolltop, so it weighs a ton and isn't easy to move.

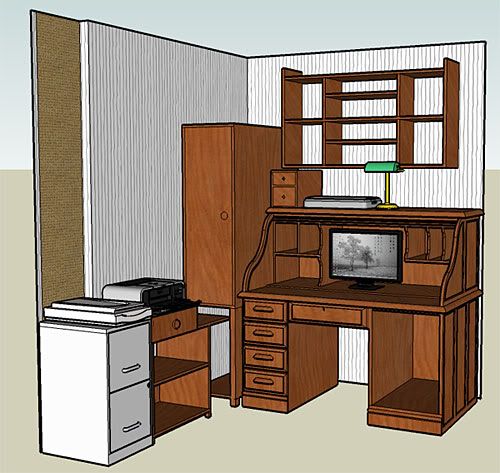

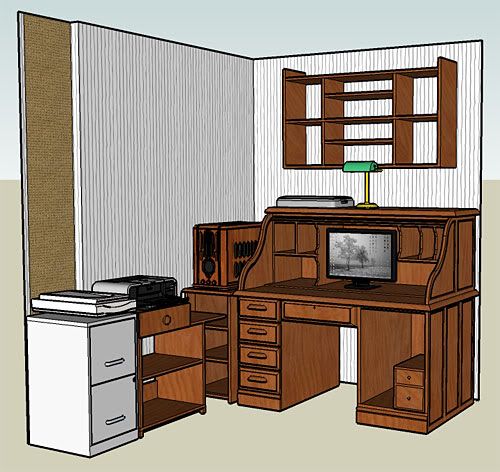

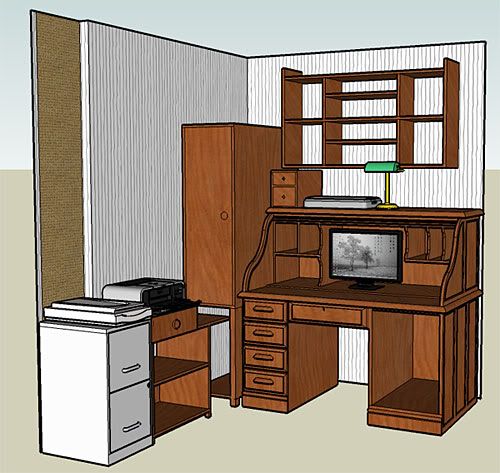

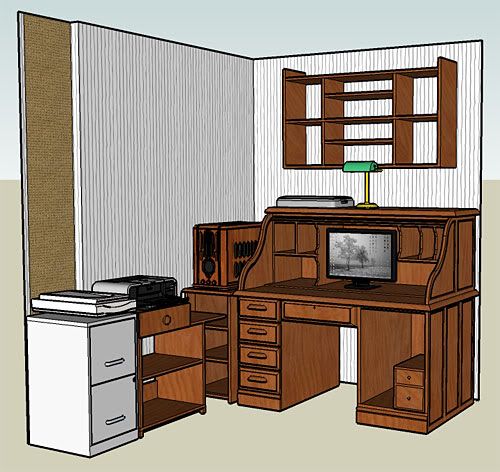

I used Sketchup to draw out my desk area to consider different possibilities. Our house isn't that large, so I'm pretty much stuck with the area that I have in our living room. I had built a storage cabinet a couple of years ago that sat to the left of my desk. This is the way my layout looks in Sketchup.

The best way that I decided to get the case out of the desk was to build a new shelf, move the cabinet into our spare room, and put the computer to the left of the desk.

However, in order to move the cabinet into our little storage room, I had to build a large shelf unit to organize it and get stuff out of the floor. So I spent about 2 ½ weeks building a large 5 shelf storage unit and rearranging everything in our storage room which allowed me to get the cabinet in there. The room needed some help anyway so this was a good time to do it. Once I got the spare room done, I moved the cabinet into it and built a shelf unit/stand for the computer to sit on.

I also moved the rolltop desk out a bit, and competely rearranged the wiring behind the desk to go along with moving the computer. I didn't want everything stuck on the carpet again where I can't get to it. I took a piece of 3” PVC drain pipe I had left over, cut it lengthwise in half, and mounted one half to the wall. This way I have all of my wiring running on top of the PVC behind my desk so it is now easy to access, neat, and can be vacuumed.

This is behind my desk now.

This is my UPS and surge protector that now are mounted on the wall behind the computer shelf/stand.

This setup is such an improvement in wiring neatness and accessibility.

Front Dial Lighting

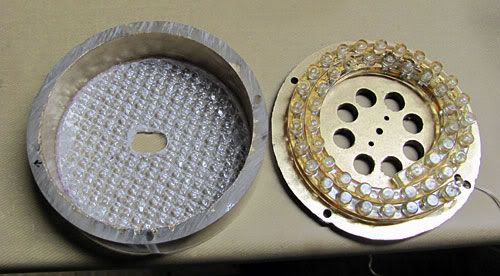

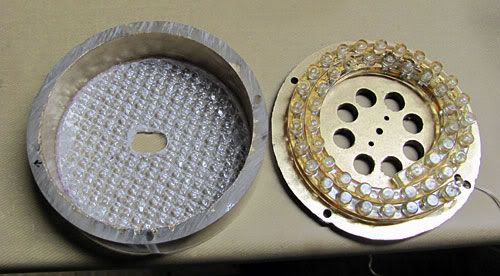

One problem that I wanted to fix was the lighting of the front dial. I had bought and wired up six 10mm yellow leds for the front dial. They are mounted in a piece of smoked acrylic attached to that back of the dial area.

There were two problems however. The LEDs simply weren't bright enough, and the light from them wasn't diffused and made 6 spots on the dial. I ordered a 48 LED flexible light string from Ebay. I used a piece of 4” acylic tubing cut 1” deep, and cut two layers of fluorescent light diffusers to mount to the front inside of the cut tubing. I took the smoked acrylic LED mount, mounted it to the tube, and painted the inside of both gold to help deflect light forward through the dial. I used RTV silicone to attach the LED light strip to the other LED lights mount.

Here is a quick pic of how the lighting worked out.

I am very pleased with the way it looks. The dial now is completely illuminated evenly.

Pump Changes

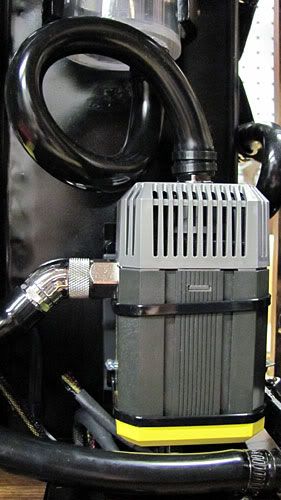

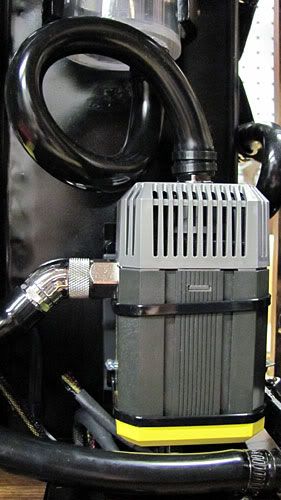

Moving the computer however up to where it is 2' from my head exacerbates the noise of having two pumps running. I wasn't really that pleased with the computer when it was sitting down inside of the desk, but having it up near my head made things much worse. I got into watercooling in the first place for quiet/performance. I have looked at the Aquastream XT before as it is said to be a very, very quiet pump everywhere I read, but have never wanted to shell out $150 for one. I found a deal however on a new unused XT Ultra on Hardforum for only $105 shipped including a soggy sandwich and G1/4” adapters, so I bought it.

The only way I could figure to mount the pump is vertically, so I made a stand/mount out of sheet metal for it. I put the rubber foam from the soggy sandwich under it and behind it. I couldn't fit the entire soggy sandwich, so hopefully the foam alone will do the trick to isolate vibrations. If it doesn't, I may opt for some Petras gel stuff.

Forming Tubing

You may have noticed the nice tight loop going from the res to the pump with no kinks. There is a trick I recently picked up here on XS. I can't find the thread now, but the idea is one of the handiest I've come across in years of watercooling. I used this several times in redoing the lower part of this loop, and it works great.

If you want to form tubing for tight bends or any bends, you can shape it the way you want, and then immerse it in boiling water and then in ice water several times. I found a spring for $3 at a local ACE hardware that fits perfectly inside of the 7/16” id tubing to keep it from kinking while forming.

For the loop in the pic above, I put the tubing into a plastic cup like this, immersed it in boiling water for a minute or two, then ice water, and repeated the process a few times.

Once heated and cooled like this a few times, the tubing holds it shape.

I have a very tight spot where one radiator feeds the other radiator. The space measured from the outside (not the inside) between the barbs is only 2 1/4” (about 57mm). The inside space between the barbs is only about 1 1/4”. Tubing would normally kink in a bend this tight. Since the piece of tubing was very short, and the bend had to be so tight, I simply used a pair of tongs to hold the tubing while forming.

The tubing formed so that just sitting the outside was only 3” apart. I had no kinking problems putting it at 2 1/4” apart.

Drain Fitting

I soldered together a fitting for the drain. This fitting was a pain in that in order to save space, I used an insert to go from 1/2” to 3/8” copper, and soldered in a 1/4” barb to 1/8”NPT fitting to be able to attach the drain tubing to. I had to go really work to get the barb fitting soldered in, and had to go back and resolder the 1/2” to 3/8” joint as it didn't completely seal the first time. Thankfully the resolder worked. I pressure tested it at 25psi with the air compressor to make sure it didn't leak.

The fitting is on the line going from the GPU to the bottom of the case around the base of the pump. Here is a pic without the hard drive cage installed so you can see the routing.

The 1/4” tube branches off, goes through the floor of the case, and has a length under the case capped off with a 1/4” barb and a rubber auto vacuum cap.

This is going to work really nice in that to drain all I have to do is take the drain line loose and it hangs about 4 inches down under the case. I can just put the front part of the case off of a countertop and drain away.

Front Grille Cloth

I made a change to the way the grille cloth is mounted. Having the front grill open allowed any sounds to come out of the front of the case, and I don't really need the cloth for any airflow. So instead of having the cloth mounted to a frame, I mounted it to several layers of cardboard, and make a solid wood piece to fit behind it. This should help redirect any sound, and also should make the cloth last indefinitely.

I'm leaktesting with air pressure as I write this. I've got to mount a new 140mm Yate Loon to the case side to replace the Xclio piece of crap fan, and hope to get some final pics up shortly. I bought a large white backdrop, and just got a new Canon SX120 that takes way better pictures than my old lousy Sony camera. So hopefully I can take some decent pics.

Last edited by voigts; 11-19-2009 at 02:48 AM.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Reply With Quote

Reply With Quote

Bookmarks