Cabinet PC

*** This project is now complete. If you wish to skip to the Complete Thread with a summary of the build log, the Link is --> Here <-- ***

I've got a decent shop, but its separated from my house (which is a good thing, so I can tinker even at night).

However, I haven?t got a PC in it, which would be useful for browsing, music, photoediting, etc.

When I needed it, I?ve been toting my laptop over.

As you can, see, my shop has got a lot of modular workstation type units, so why not a PC?

Important concept notes:

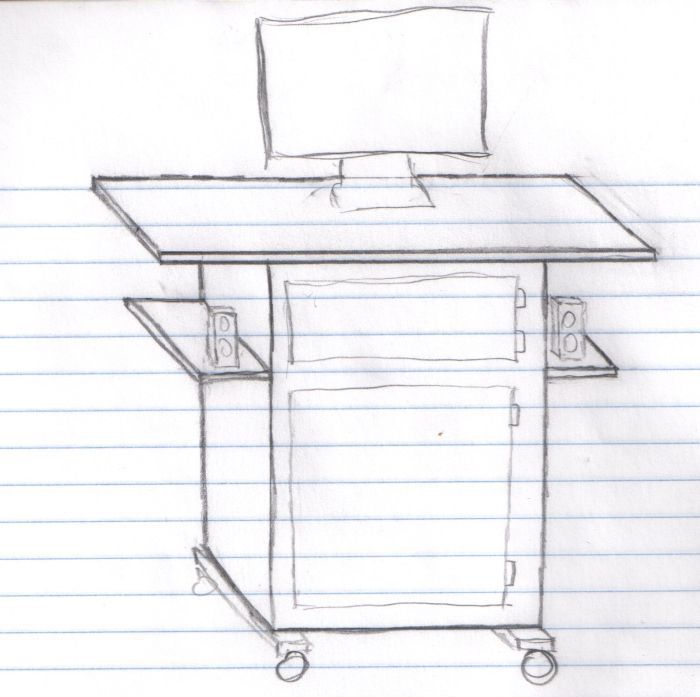

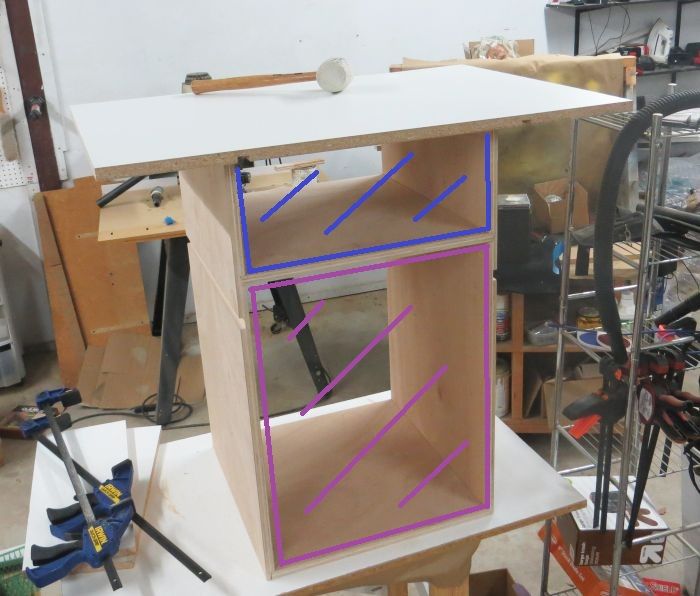

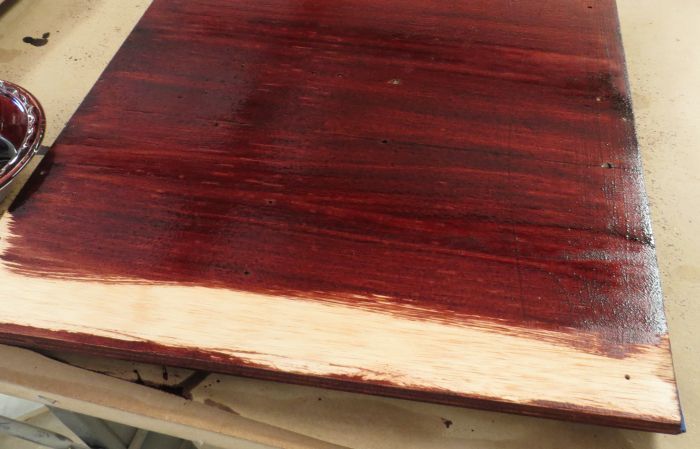

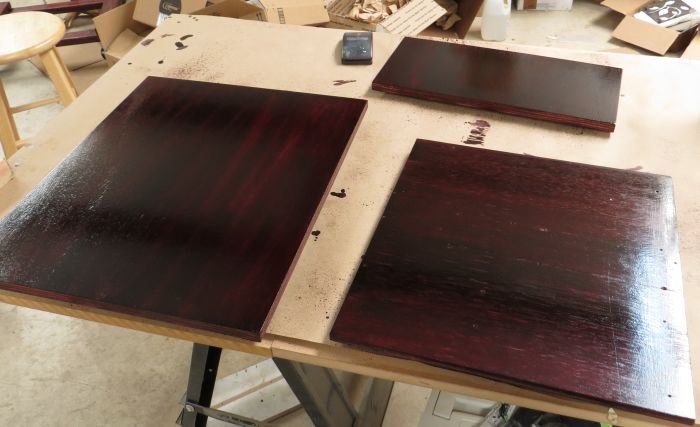

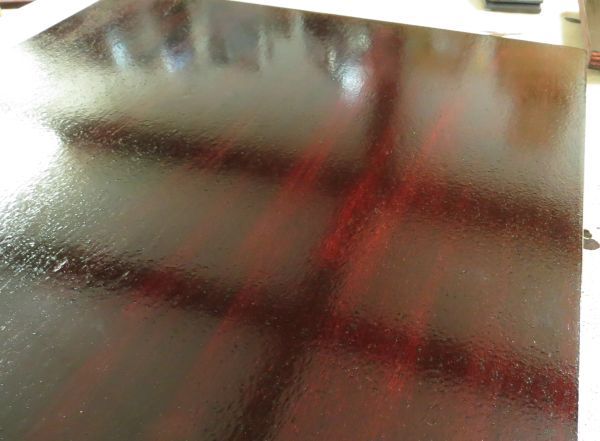

1) Built on a simple cabinet structure, with a desktop

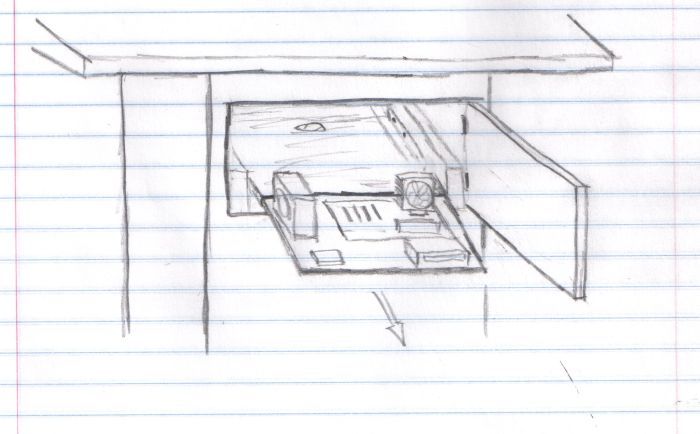

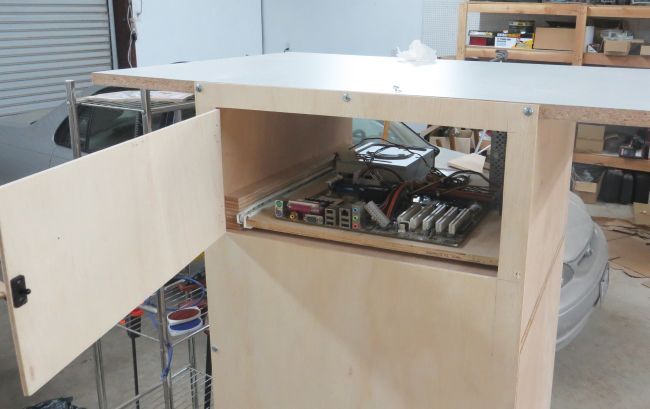

2) PC mounted on a pull out shelf unit

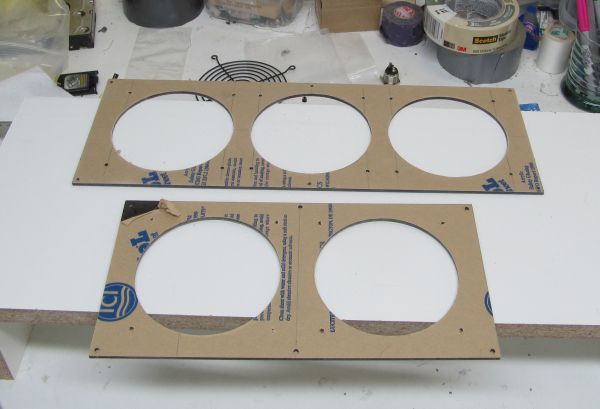

3) Speakers for music

4) Mounted on wheels

5) This one is meant to be a quick and simple build--focus on function and low cost. Aesthetics are taking a back seat. Not really for performance either, the PC is going to be cobbled together components.

Reply With Quote

Reply With Quote

Bookmarks