that's a bit surprising from EK... hope it'll be allright with no leak!

that's a bit surprising from EK... hope it'll be allright with no leak!

doctor pepper's desk

EVGA P55 FTW | i5 650 @ 4GHz | 4Gb Corsair Dominator DDR3-1600 XMS3 | XFX 4870 1Gb | Corsair X32 | Samsung SpinPoint F1 - 320Go | Fractal Design Newton R2 650W | Samsung P2450H | Microsoft Laser Desktop 7000 | JBL Spyro Black

AirCooling: Prolimatech Mega Shadow | Xigmatek Bifrost | Fractal Design SATA Cluster Box | Fractal Design 2x120mm, 2x140mm and 1x92mm

Cosmos-S

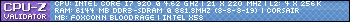

Foxconn BloodRage Rev1.1 Bios P07 | i7 920 D0 @ 4,629GHz max & 4,3GHz stable | 6Gb Corsair Dominator DDR3-1600 | XFX 5870 | Sonar X-Fi | Intel X25-M 80 Go PostVille | Samsung SpinPoint F1 - 1To | Corsair HX620W | CoolerMaster Cosmos S | Samsung T240 | Logitech MX-5500 & Z-2300

Watercooling: Laing DDC + plexi top and tank | CPU - HK 1366 rev 3.0 LT | GPU - EK Water Blocks EK FC5870 V2 - AcÚtal Nickel | MB - Foxconn's original | HDD - HK SilentStar HD-Single rev 2.0 | radiator - 3x120mm | tubing - High Flex 10/16mm | red PrimoChill ICE coolant

So I went to a metal chop a few days ago to buy some metal for the build. I've cut them to the right size to fit the case:

And this should give you an idea for the next step:

The whole back panel will be swapped for 2 aluminum bars.

and there lies the next problem.

Apparently the front, down and back panel is one piece.

Let's get the Dremel!!

.JPG)

Great Job so far bro !!, Im gunna watch this Build !

looks good

weird about the rads though.

I think your radiators were exposed to different temperatures for their paint to dry... at least explains the paint shine difference.

Signatures make my posts look huge... but I'm not humble enough to completely remove my signature, so I kept this note explaining it.

Update Cut-Up.

So I've made some progress on the case.

Like I said in the previous update I had to use the Dremel for some work:

Luckily that the thing still works...

This is where I started cutting the case:

After removing some rivets:

Started filing so that the frame would fit better and look nicer:

Some small adjustments to the case to fit the structure:

I shortened one of the profiles to the right size because it is not as wide as the lower section:

And this is how it still stands in the garage:

.JPG)

Some more pictures from the vertical support-brackets:

And a few minutes later al the work was done:

you wish...

Measure twice, drill once. The exterior dimensions need to be the same as original to fit the side and top panels.

A bit after the second one goes on:

Immediately found a problem while trying to mount the top panel:

Solution:

For finishing a not so quality shot:

.JPG)

This update is all about the side-vents in the sidepanels.

I first need to make the side-vent to know at which height the radiators need to be.

Nicely taped and marked for cutting.

To bad no pictures from the cutting itself.

Here is the result after some hard work: filing!!

Here are the tools:

Apparently the big file is meant for wood. Didn't know that but it worked !!

That's it for this update. It's a bit calmer because I have some tests I have to redo next week. So more studying than working on the mod.

It's been a long time since I posted the last update.

That was because I had 2 tests I had to redo in August. This Monday I had the last one. Now I only hope I passed...

Tuesday was a day to rest a bit and I started Wednesday working on the mod again.

What has already happened?

I had the materials so I started working on the mounting bars for the radiators. Don't want them to be placed loose in the case.

It's no really quality work (pictures and case) but It works so I'm happy. And it's not like you are gonna see it when the radiators are in the case.

At the beginning the garage was still relatively empty:

A mock-up for the radiator mounting.

A shot from the distance:

That was just before the tape let loose and the radiator fell, luckily not to the floor but it remained in the case.

This is how it looks on the outside:

I used the "bad" radiator for mock-up because it already has a bad paintjob and will be repainted later so a few scratches more or less don't matter.

Also went to the shop for some supplies:

40 rivets:

.JPG)

And 2 steel plates which will be used for the motherboard-backing-panel.

And that is the next thing on schedule.

Comments are welcome.

See u next time.

Plenty of space inside of that case, these two rads should be more than enough.

I'm not sure about quality of cuts in side panels, it is so easy to scratch that burshed aluminium layer. You would get much better results sending it for laser cut. Same with painting/powder coating, it almost always looks worse than original, even if it seems better on some photos. Anyway, good luck with your project.

Started working on the support bars for the midplate:

Tapping to M4:

Then I realize that the plate I bought are not long enough for the case: they are only 50cm long.

Started measuring for the backpanel for the motherboardtray on a steelplate.

Let's see if it's correct:

Ti bad I won't have any room for a 120mm fan but that won't be nescary since most of it will be WC'ed.

Then another "eureka" in a negative way. I don't have a cutting bit for steel. So me back to the shop to buy an aluminium plate and redo the work.

A little while later:

And this is how it will go onto the case.:

With the dimensions I have for the currant backpanel, I'd have to modify a lot to the original motherboardtray to fit it. So I have to adjust some dimensions for the backpanel and redo the cutting.

It seems like modding doesn't go as planned every time...

Long from Death

No silent death for this mod

The last Motherboard panel was a bit of a fail because I forgot to include the motherboardtray to the dimensions. Result: to much work to get the tray to fit. Solution: New motherboard panel.

Here it is:

It's still a bit loose but hopefully that will change this weekend.

The motherboardtray:

.JPG)

Vote for me plz

http://forums.bit-tech.net/showthread.php?t=197751

Nice idea for radiators placing. LianLi

As you might have noticed, I ordered some aluminium plates and mesh, all custom dimensions.

Nicely packed to avoid damage:

The contents:

All custom made

In the next updates you will know the uses of the content.

What is supposed to be done today and what should have been done al long time ago:

Mounting the midplate, here is a mock-up:

Preparations to mount the radiators:

I've downloaded the radiator-template from MNCPTECH for finding the right place for the mounting-holes. Prevents most of my screw-ups... Hopefully

I also scrapped the top mounting-rail for teh radiator to fit a larger one that is also used for the mid-plate.

Finding the right holes:

Drilled some holes:

Some work-hours later:

End of this update!!!

.JPG)

Bookmarks