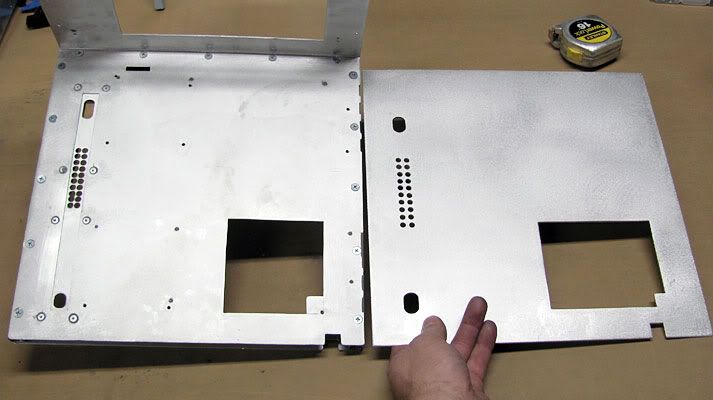

that is so true. i really don't want to spend the time to redo the MB and PSU panels, but I just can't live with them like they are. At least this time i think they will turn out very good since I've had practice.

I just came in from spending 2 hours working on my mother-in-law's poor ragged out rusted car on this "vacation" of mine. I now have to go run to the auto parts store so i can come back today and spend some more fun "vacation" time. The plus side of this is at least I'm not at my normal job.

It's never as fast as you want, but I think that's the nature of modding.

It's never as fast as you want, but I think that's the nature of modding.

Reply With Quote

Reply With Quote

?

?

.

.  .

.

(I blame the 'q' in 'liquid'

(I blame the 'q' in 'liquid'

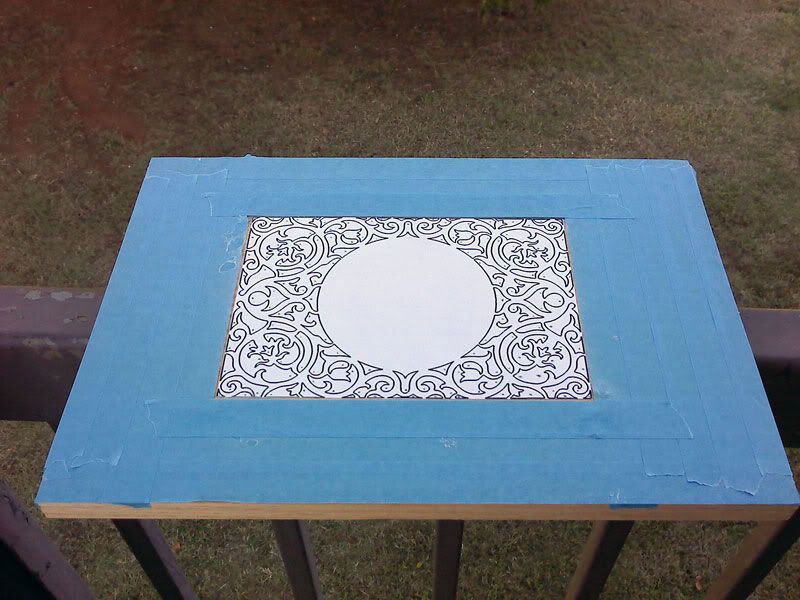

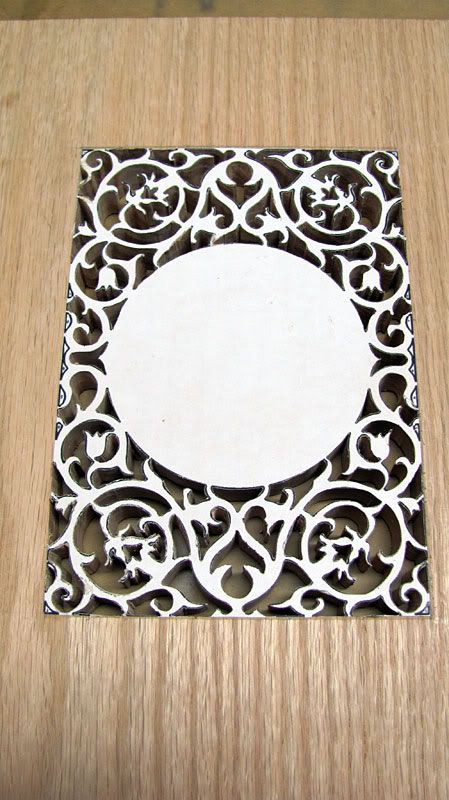

! Good luck sawing/drilling all those little designs

! Good luck sawing/drilling all those little designs

Bookmarks