Quintessence: (from Dictionary.com)

1. the pure and concentrated essence of a substance.

2. the most perfect embodiment of something.

3. (in ancient and medieval philosophy) the fifth essence or element, ether, supposed to be the constituent matter of the heavenly bodies, the others being air, fire, earth, and water.

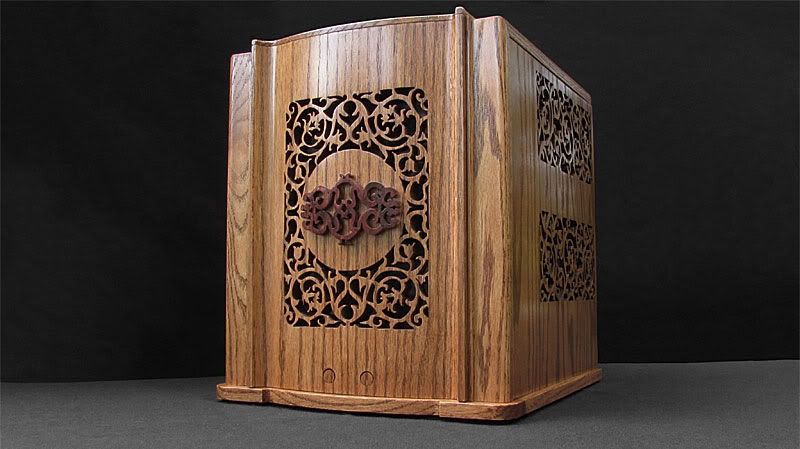

I hope this build will end up being a good incorporation of antique styling, elegance, function, and performance.

Featured in the August issue of CPU Magazine

FINAL PICS ON PAGE 9

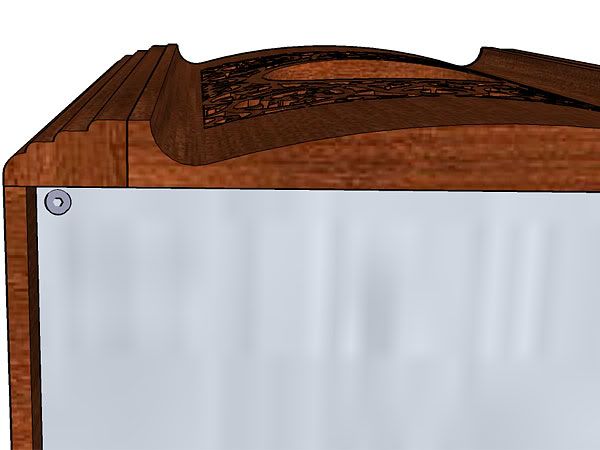

Current Renderings:

-------------------

List of Updates:

The Build Begins - Cutting out panels and bending aluminum for base 26May2010

Transferring Spacing for Cutouts on PCI Panel and Mounting Holes in MB tray - 31May10

Panel Work - 16Jun10

Putting Parts Together, PSU & HDDs Mounts - 22Jun10

Motherboard Mounted, PSU Wiring Insert, Decide to Remake MB Tray and PSU Panels -03July10

Redone MB tray, PSU tray, Top Panel, and Center Spacer/Support -03Aug10

Base Pieces Assembled, Center Airflow Divider in Place, GPU Fans Mount in Place- 22Aug10

Starting Front and Top Scrollwork - 20Oct10

Front and Top Scrollwork Cut Out - 10Dec10

Front Panel Contour - 21Dec10

Front Panel Scrollwork Sanding Done -02Jan11

Top Panel Scrollwork Sanding Done -19Jan11

Edge Moulding - 23Jan11

Bottom Radiator Mount - 26Jan11

Top and Front Panels Mounted - 01Feb11

Top Panel Front Sanded Flush and Base Cut and Mounted - 03Feb11

Edges of Top Panel Routed & Various Adjustments - 05Feb11

Power and Reset Buttons, Radiator Drain, Res Plans - 12Feb11

Bottom Radiator Leaktested, Mount Remade, and Airflow Piece Done - 15Feb11

Reservoir Made/Mounted and USB Port Mounted - 22Feb11

Res Cleaned up and Polished - 24Feb11

Bot Fan Assembly, Rear Grille, New Parts - 22Mar11

Side Panels Scrollwork Cutout - 04Apr11

Side Panels Mounted - 10Apr11

Steam Bending, Fillport, Wiring Cover, Fan Contr- 23Apr11

The Painting Begins - 30Apr11

Putting in Parts, Lighting, Watercooling, etc. Part 1-11May11

Putting in Parts, Lighting, Watercooling, etc. Part 2-21May11

Forming Tubing, Flushing, Filling - 03Jun11

FINAL PICS ON PAGE 9

-------------------

I haven't started building anything as of yet, but have been again spending time in Sketchup modeling what should become my next build. I'm in no hurry with this build, and have been gathering better tools and materials over the last few months. On this build, I plan on using an aluminum frame with a wooden shell. This should allow easier access to the case internals as I plan on having the side and top wooden panels merely stick on via magnets, rather than have the frame made out of wood. I haven't decided on what wood to use yet, but now that I know I have a local source for hardwoods and hardwood plywoods, I plan on using something like Cherry or maybe Walnut that isn't very grainy. My objective here is to design a case that is as small as possible yet incorporates 6x120mm rad cooling. I will be using a Micro ATX MB. Although the renders show black behind the front panel, I will probably put an opaque sheet of acrylic behind it with lighting so that the front fretwork will be lit up. Underneath the top piece will be mesh. I also want the case to be laid out in a way however that allows for access to the components without unnecessary complication.

For the first time, I've started working with Kerkythea on rendering to give good clear pics of what I have designed in Sketchup. I would like to get feedback/criticism/ideas on this design. Let me know what you do/don't like about it and why. Any constructive help on the renderings themselves is also welcomed as these are my first attempts. Thanks.

Thanks for taking a look.

Reply With Quote

Reply With Quote

) down into, say 3mm/3/16th sheets. Then you could laminate the sheet back together but with the right size radius cuvre in it.

) down into, say 3mm/3/16th sheets. Then you could laminate the sheet back together but with the right size radius cuvre in it.

Bookmarks