I believe so. lol... The black I've ordered awhile back I cut up in 6" sections. I believe it is! I'll be ordering more soon.

You got some great skills my friend. Love looking at your sleeving work. Best of the best man...

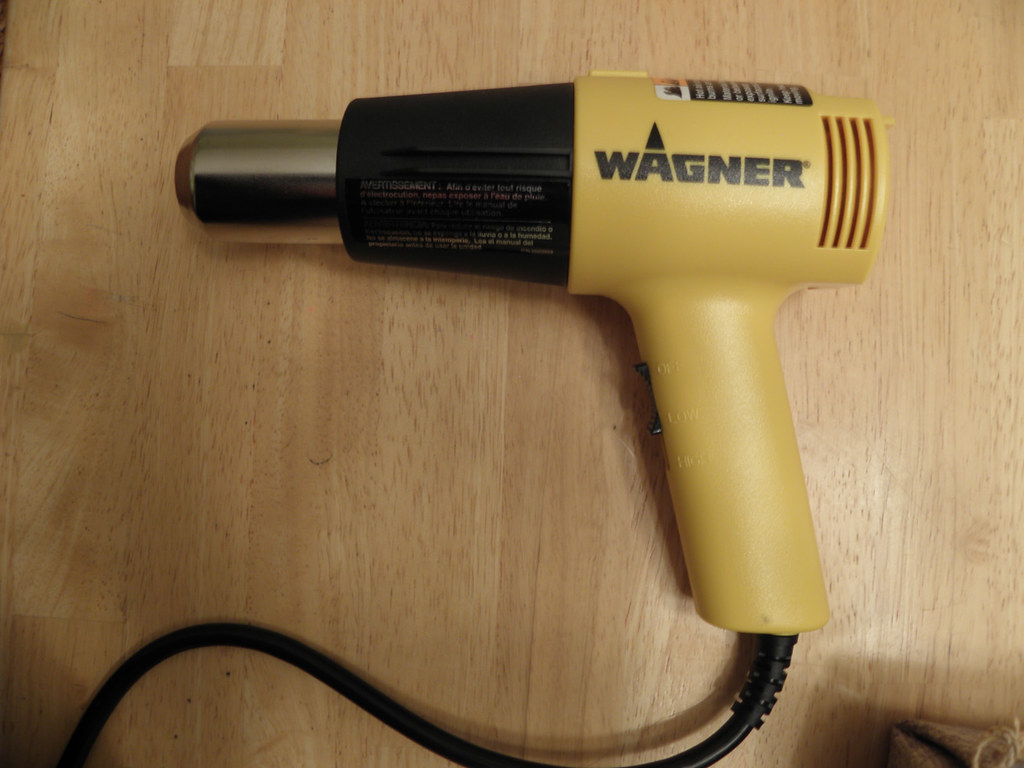

P.S. I know this is strange, can you post a pic of your heatgun? You using a metal shroud at the end of your gun as well to keep the heat constrained?

Reply With Quote

Reply With Quote

Bookmarks