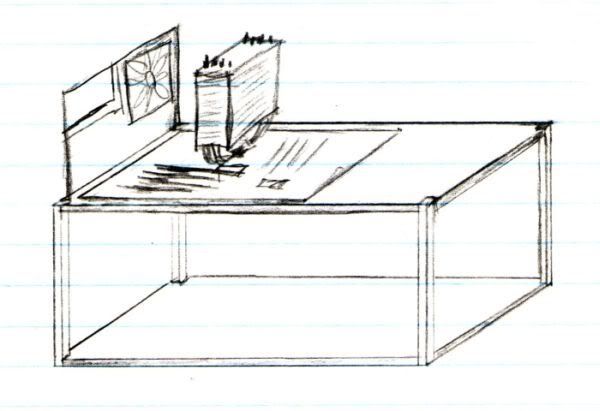

I introduce a brand new modification project presented to you by IKIKUINTHENUTZ with the famous and elusive Navig Tech Station handmade by Navig himself with design aided by Thideras!

Now let me let you know the little history about Navig Tech Stations how this particular station was transferred to my ownership and why I am modifying this hand built wonder.

Back in 2007 a little wonder named Navig on OCF & Abit forums (now dead) was creating something called, Navig's AWESOME DIY station. He created a thread to record his progress http://www.ocforums.com/showthread.php?t=528477 and began building his little monsters.

The project was simple, to create a better tech station that was easy to work in and cost less than the competition. Long story short the project was successful and he begin taking orders for his made stations.

Link to where he sells it. You need to be OCF member and have 100+ posts to view it.

http://www.ocforums.com/showthread.p...ighlight=NAVIG

One month after the success of the first station. A little OCF member named Thideras posted on 12-30-07 to request Navig himself to build a station to exactly to his specifications. Navig obliged and a custom design was created just for Thideras.

Details of this transaction is located in this link but to view you must be a member of OCF and must have 100+ posts to see this thread

http://www.ocforums.com/showthread.php?t=541522

An image of Thideras using the station

In 06-19-2008 Thideras was selling this hand made wonder. I, IKIKUINTHENUTZ did not hesitate jumping on to the deal. Ownership of the station was transferred.

I used the station for my work, testing products, a temporary parts holding before transfers, overclocking. Day by day I hated the station not because of the usefulness and functionality, in three simple words, it was ugly.

Honestly I am a picky ass bastard when it comes to looks. Being a Lian li OEM case owner or my love for those shiny Thermalright rip off heat sinks and my awe for those nice practical (acceptable for everyday use) case projects other people posts, this fella I had no love for, I abused the poor thing without care because I just didn't like how it looks. The ugliness became so much, six months ago I dismantled the bastard and stowed it away in my closet.

In may I finished my HTPC project (http://www.xtremesystems.org/forums/...postcount=5001 , http://www.xtremesystems.org/forums/...postcount=5026). Soon after I was cleaning my closet, I found this little monster dismantled. I forgotten about it but I remember why I took it apart, it was ugly. I didn't want to throw it away but to store it into the garage. Later I went into the garage and found black and white spray paint my dad doesn't use anymore. It begins.

While painting the parts without much care, I thought to myself, " hey these screws are fugly" I went online to mcmasterscarr.com and order a tons loads of button cap screws of lots of sizes to replace the zinc coated fellas with stainless steel socket button caps. It looked very nice but soon after I was done. Fun money ran out and I halted the project completely.

Until a few weeks ago with my funds rejuvenated I was pondering if I wanted to continual this project or just stow it again. Thankfully the new XS member whuzabi inspired me with his white murder mod. http://www.xtremesystems.org/forums/...d.php?t=225829

Me and whuzabi talked and we shared ideas. Long story short, the chat made me decided I'm going to put some major effort into this into something worth while!

I found some old paint used long ago when my room was being painting. I also went to a Local Ace hardware store and got some spray polyurethane stuff (I might exchange it for the brush on type).

I sanded off the old ugly spray paint I used and decided to use rollers to paint the wood in order to put the most amount of effort into it. First is primer. I'll keep you guys updated, enjoy. I have some plans to help me get this aided and done.

Current Sponsors:

NAVIG

Legal Disclaimer:

I Andy (aka IKIKUINTHENUTZ) is not the original concept owner of this bench station. All concepts sans alterations by me are owned and created by Ivan (aka NAVIG). All images and work may not be reproduced without consent from me or Navig.

Reply With Quote

Reply With Quote

Bookmarks