I posted this elsewhere, but it seems like it didn't generate much interest, so I decided to start a new thread.

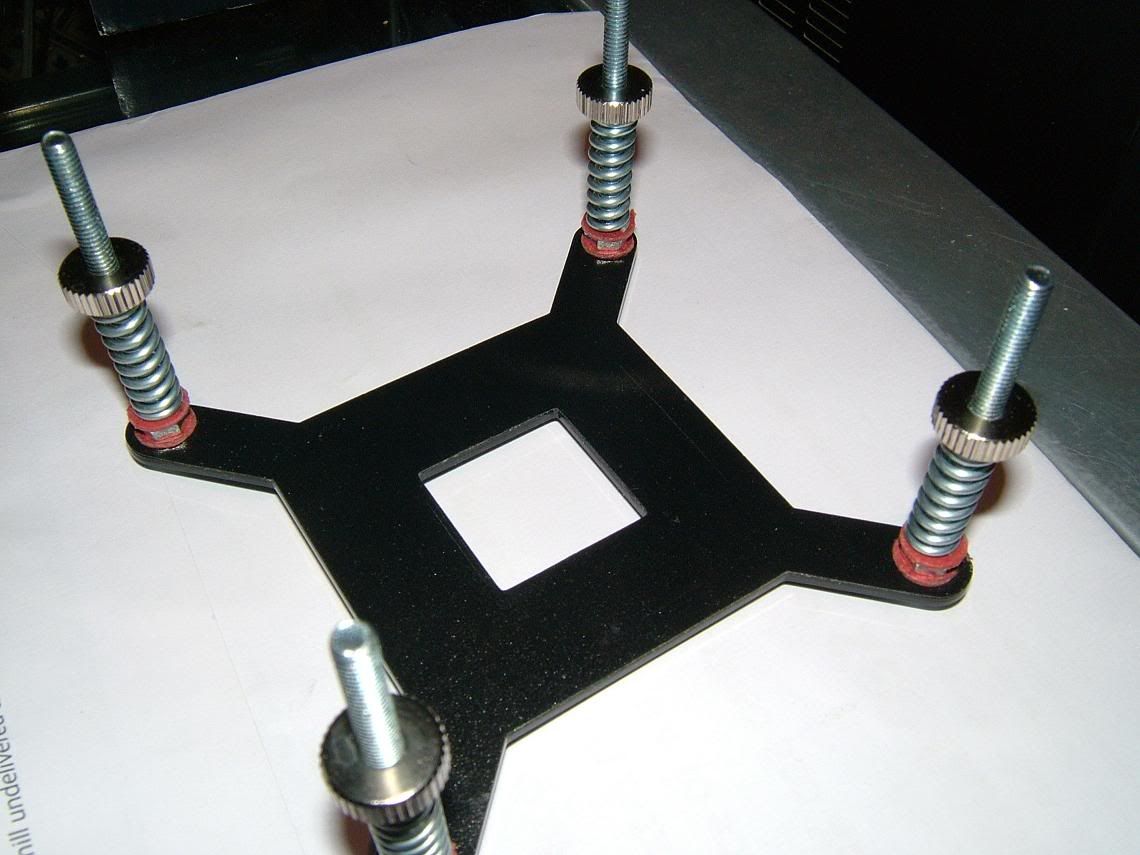

There are several vendors already with Ci7 waterblocks, but unless error or omission on my part, I don't see any of them with an adequate motherboard back-plate.

Swiftech recommends the use of an extended back-plate where high clamping pressure is applied (typically to improve TIM joint). By "extended", we mean a supplemental back-plate to reinforce the stock solution. Here is why.

The distance between mounting points in socket 1366 is quite a bit larger than that of socket 775. As a result, the motherboard is subjected to much higher flexing forces because of the leverage effect. This is the reason why Intel specified a back-plate with this socket. In Desktop applications, this back-plate is barely larger than the socket though.

One may wonder why the stock back-plate does not extend all the way to the mounting holes, and the reason is simple: in mass market applications such as Desktop, I suspect that OEMS are expected to use the Intel stock cooling solution which snaps into the motherboard without removing the later from the case. In this scenario, the mass (affecting dynamic forces -occuring in shipping for example) and clamping pressure (static forces) of the stock cooler are adequate with respect to motherboard flex and the existing relatively small back-plate.

However, in server applications where heavier cooling solutions are needed (imagine a large passive heatsink for a 1U application for example) it would be logical to speculate that one-piece back-plates fully extending to the mounting holes and featuring sturdier fastening mechanisms will be the norm.

I make this point to illustrate the fact that an extended back-plate is highly recommended to prevent excessive flex of the motherboard in heavy duty cooling applications. Not because of the mass of the water-blocks obviously, since they are all much smaller than massive copper sinks, but because of the high-clamping pressure (static forces) that we -overclockers typically apply to improve our TIM joints.

If you add to this the fact that some vendors release crude (dangerous) retention mechanisms which allow end-users to crank the pressure much beyond what the PCB traces can safely sustain, one can be seriously concerned about damage to the motherboard.

We at Swiftech spent a great deal of time (and $) developping a retention mechanism that is both effective AND safe.

So when you guys are looking for cooling solutions out there, all I can say is: buyers beware!

Reply With Quote

Reply With Quote

PM me.

PM me.

.

.

Yeah, the difference being that those have a 'bottoming' out screws and are (mostly) notorious for 'bad' mounting pressure. In reality, the pressure has always been great on a TRUE, just the mounting design allows twisting, which leaves most users unsure (for good reason). Still, adding pressure did seem to help

Yeah, the difference being that those have a 'bottoming' out screws and are (mostly) notorious for 'bad' mounting pressure. In reality, the pressure has always been great on a TRUE, just the mounting design allows twisting, which leaves most users unsure (for good reason). Still, adding pressure did seem to help

Bookmarks