Hi Alex,

Honestly, I think we're both getting into a realm that we don't know enough about to discuss/debate/decide what's going on. All I really know is from my past experiences dealing with pumps. Hopefully, someone else will come along and help explain what's going on.....

A quick update on my setup:

The car rad arrived yesterday and I have been working my butt off to get stuff done. Basically, everything is done (no PCs involved yet)--with 3 minor issues:

1) I need a frickin' radiator cap!

What pisses me off is that I went to walmart and the hardware store today--forgot all about stopping at the auto parts store....errrrrr

(Autozone has one in stock--$4.99

)

2) The caps for the blue barrel are leaking again where I drilled and siliconed. Not a big deal when the system is running, but during a long power outage--there will be some leakage (~3gals). I'll have to pick up some more caps at work and come up with a new plan for sealing them.

3) Have to figure out a way to plug the radiator "overflow" vent. Not a big issue, but can't run the system until its done.

With 1 & 3 completed--I'll be able to run the system, until I can get #2 done. Either way, right now, I'm tired.

I've taken lot's of pix, so I'll see about putting a new thread together before long.

Best I can tell ATM is that I will still have plenty of flow. Just can't run things long enough right now to really check it out.

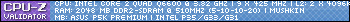

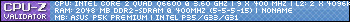

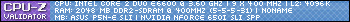

I have a Q9450 coming tomorrow, the PC tubing and some other stuff. 2x UPS and 1X DHL. I may run out and get the rad cap

Crunching XS:

Crunching XS:

Reply With Quote

Reply With Quote

The 3 rows not only offer good cooling--but better flow also. I'll have to take a look when it gets here, but I think it'll work work whether the tubing is round or flat. We'll see....

The 3 rows not only offer good cooling--but better flow also. I'll have to take a look when it gets here, but I think it'll work work whether the tubing is round or flat. We'll see....

I'll git-r-done.......

I'll git-r-done.......

Docsis3.0

Docsis3.0 ---Sometimes it takes me a minute to catch up!

---Sometimes it takes me a minute to catch up!

Bookmarks