MM Extended U2-UFO CYO (Duality front, Standard back, Horizontal Mobo brace) Anodized Black || eVGA X58 || Intel i7 920 || 6 GB Corsair Dominator PC3-12800|| eVGA 295GTX || Asus Xonar Essence STX || VisionTek 650 TV Tuner || 1 300GB WD Velociraptor || 1TB WD's Black Ed. || LG 22X DVD-Writer || Lite-On 20x DVD-Writer || Corsair CMPSU-1000HX PSU

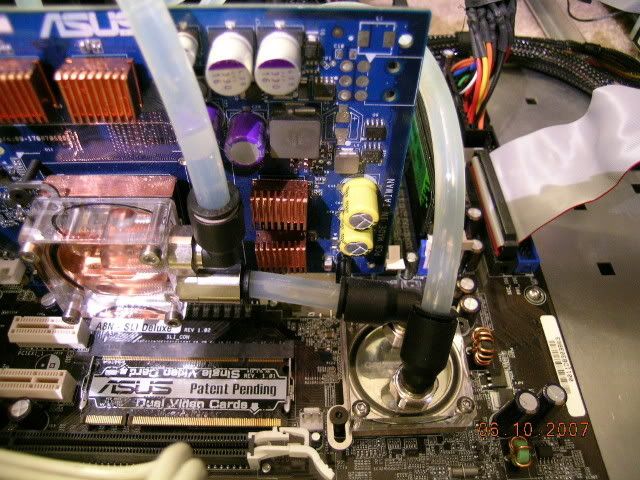

CPU Loop: DDC-2 w/ XSPC Reservoir Top -> Swiftech GTZ -> Thermochill PA120.3 (Push: 3 Scythe S-Flex G)

GPU Loop: DDC-2 w/ XSPC Reservoir Top -> (Koolance VID-NX295 FC block) ->Thermochill PA120.3 (Push: 3 Scythe S-Flex G)

Chipset Loop: DDC-2 w/ XSPC Reservoir Top -> Alphacool Silentstar Dual HD waterblock enclosure -> Bitspower Black Freezer eVGA x58 MOSFET-> Bitspower Black Freezer eVGA x58 NB -> Thermochill PA120.2 (Pull: 2 Scythe S-Flex G)

2 x Dell 2408FPW LCD || Logitech Z-5500 Digital 5.1 || Logitech G9 Mouse || Logitech G15 LCD Keyboard || Logitech Quickcam Ultravision || Sennheiser Headphones

Reply With Quote

Reply With Quote

The fun is in building them.

The fun is in building them.

Bookmarks