First, the materials:

Dielectric grease; acrilic Conforming Spray (PL2); varnish and Artic Ceramique, because it is the best for low temps.

Secondly, an insulator that prevents the air passage, as armaflex or even better, neoprene

We start with the motherboard, first with the back, clean it before, then apply a layer of conforming spray (pl2)

I preffer to do it over the whole mobo, just for extra precaution.

We let it dry and we applied a second layer,it has to be applied at 30cm away from the mobo, in a well ventilated place

Once it's dry, we go with the front part of the motherboard

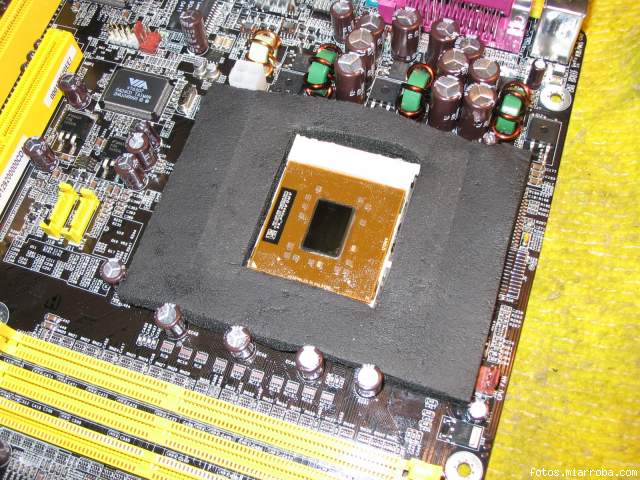

First, apply a varnish coat around the socket (NOT OVER THE SOCKET, OR WE WILL HAVE A DEAD MOBO)

Let it dry for 10 minutes, you can speed up with a hair dryer.

Ok, now it's time for the dielectric grease, (I use Dow corning compound 4)

Apply gently over the socket in both positions, open and closed with your fingers

Then, you can apply it also around the socket, over the varnish, maybe overkill, but I never had probs with condensation this way

Now leave your local insulator profesional give you the thumbs up

he saids it is ok, we can keep working now

Again, apply some dielectric grease over the conformal coating spray behind the socket.

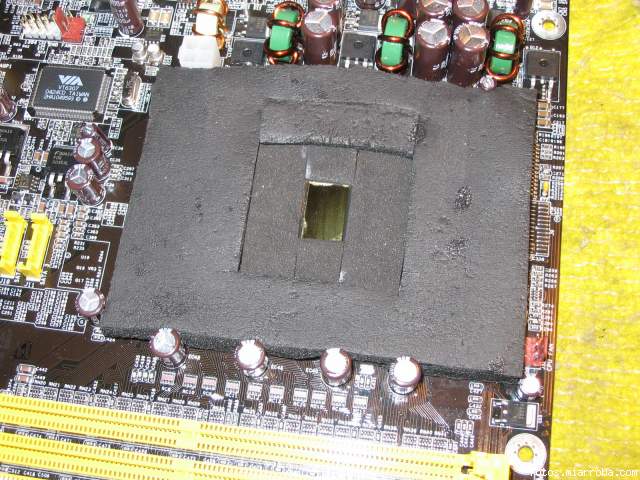

ok, now cover it with a piece of armaflex just to not get more messy than it needs to be.

Back to the front. We have to cut an armaflex gasket for the socket, and easy way to do it is to press the armaflex over the socket to get an imprint of the socket in the armaflex, then cut the hole.

For those that took the IHS out of the proc, you can apply varnish, and dielectric grease around the core

I also used a piece of EVA rubber around the core as protection and insulation also.

I know, my english sucks

Nothing makes me more mad than translations.

Whatever.

PD: Moderators can "fine tune" my ugly english.

Reply With Quote

Reply With Quote

Bookmarks