I'm thinking 1mm but I am not sure.

Somebody know for certain?

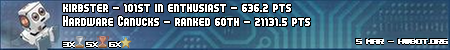

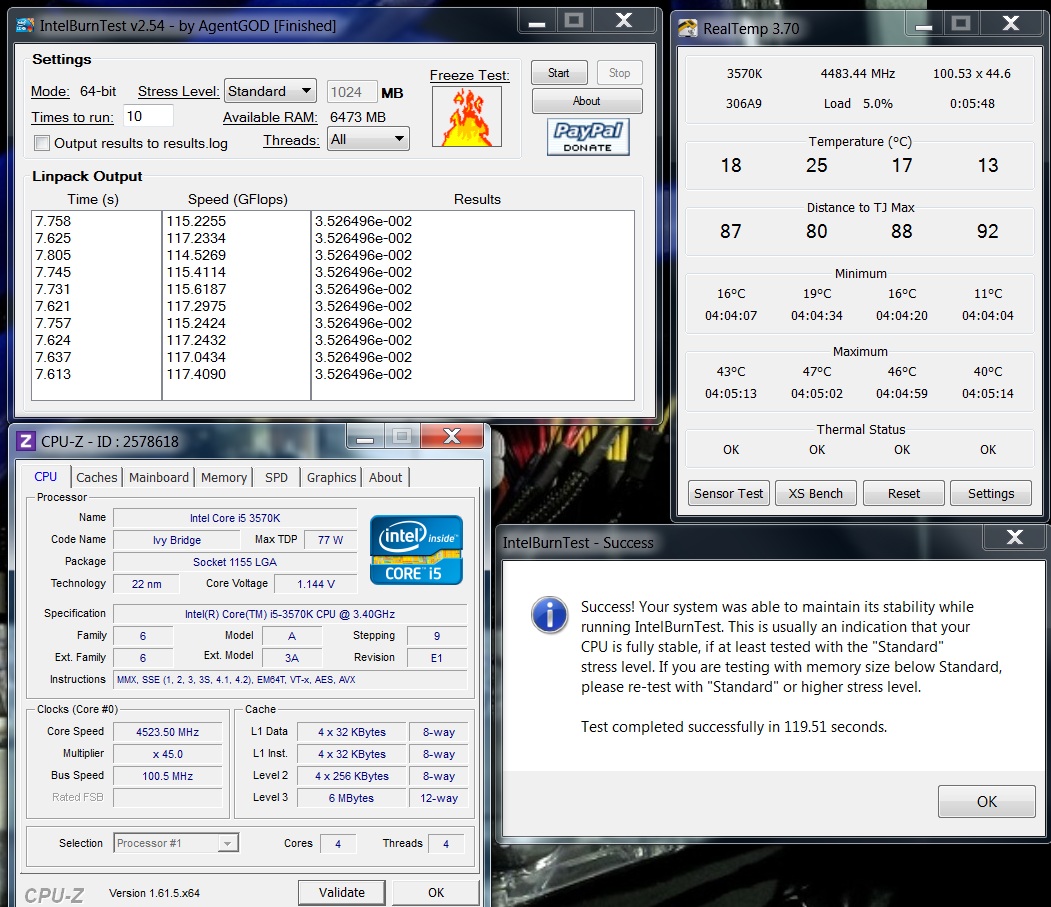

I recently De-lidded my i5-3570k and my temps dropped over 12C average per core with direct die mount. NO IHS.

Thinking of ways to improve my cooling I have come up with a mod that might work.

I want to lay down a perfectly cut non electrical conductive thermal pad around the die.

It has to be just the right offset so that it doesn't interfere with the contact area of the bare die yet is thick enough to make good contact with pcb and my water block.

Goal of this mod is to increase the contact area to increase thermal transfer from the cpu.

I'm looking at these thermal pads from FrozenCPU.

http://www.frozencpu.com/cat/l3/g8/c...ads-Page1.html

Reply With Quote

Reply With Quote

I think it is possible since most thermal pads do give way. 1mm may be the perfect size.

I think it is possible since most thermal pads do give way. 1mm may be the perfect size.

Bookmarks