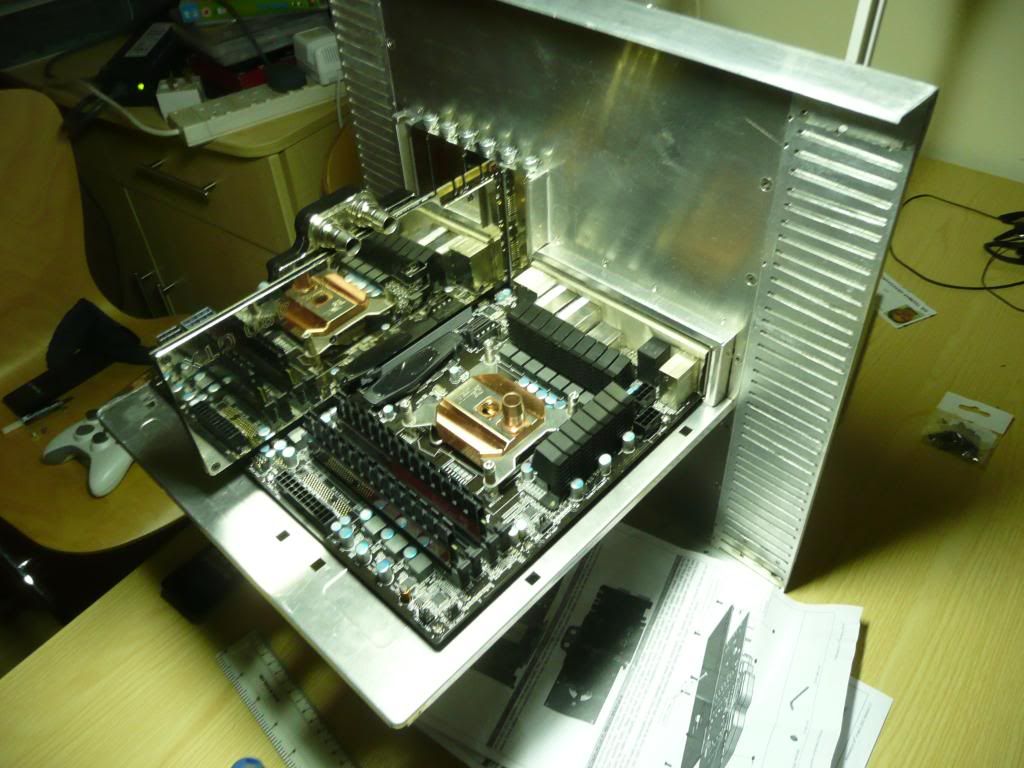

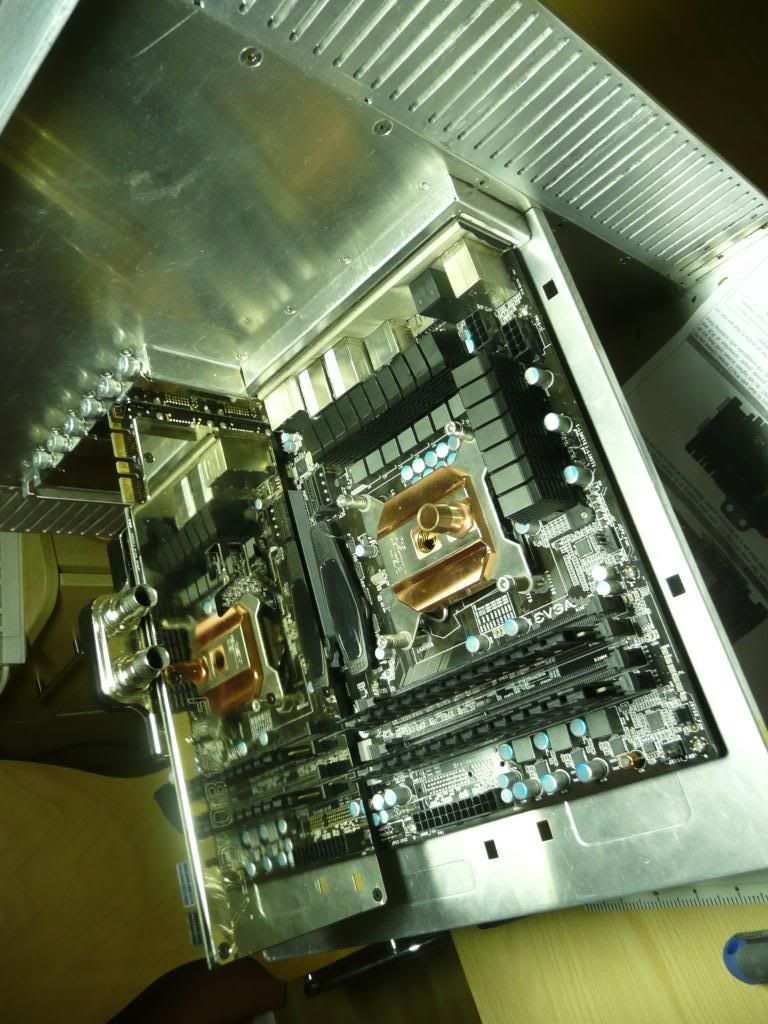

I think I worked out it weighs around 34-35kg (5st) fully filled with hardware and water (it holds about 1.7 litres of water btw). Weighs about 25kg unfilled. Very heavy but not unmanageable.

I have dabbled with the idea of running some fans. Would probably go for 9 x 120mm fans on an automated fan controller though as there are much higher quality fans available in that size. I bought a sanyo denki 9S1212L401 1500rpm fan and a 1450rpm Scythe gentle typhoon, and whilst they're both superb fans (if somewhat pricy), they're unnecessary as temps are fine atm. Who knows, might go for that if I start runing multi-GFX cards down the line and temps get out of control. Would be nice to have fans that stay off until temps get dangerously high.

Thanks Vetalar!

Two car radiators would suck for passive airflow though.Why would someone design and build their own case from scratch in order to save time and money?

besides which, watercooling has come on a bit since car radiators...

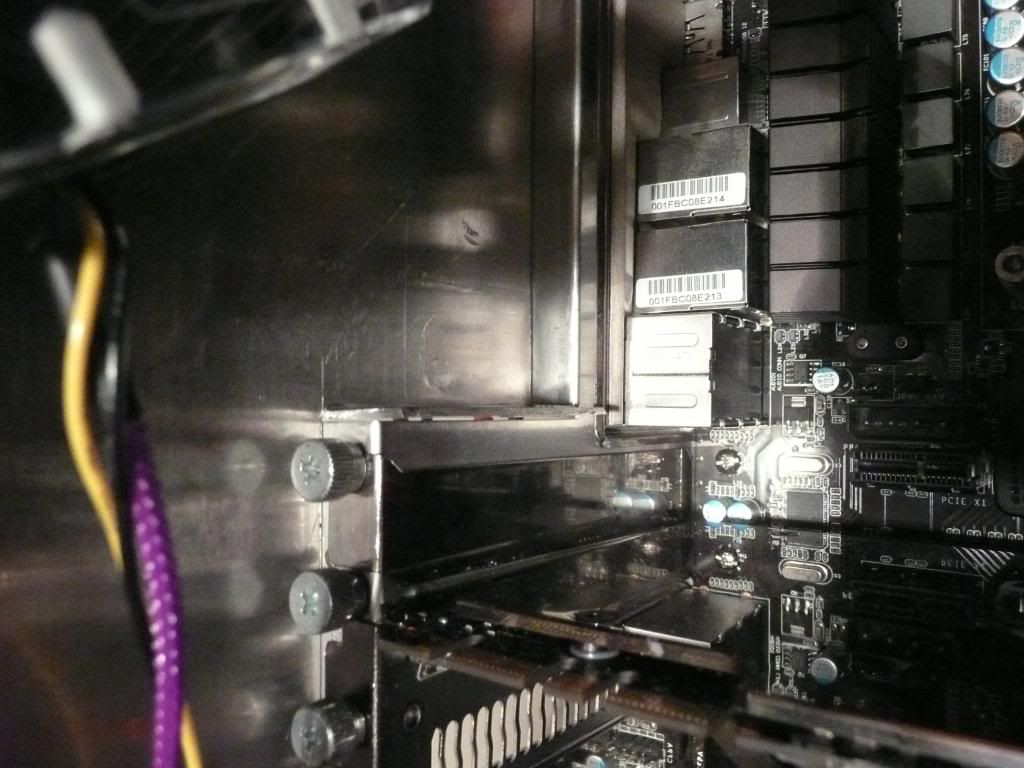

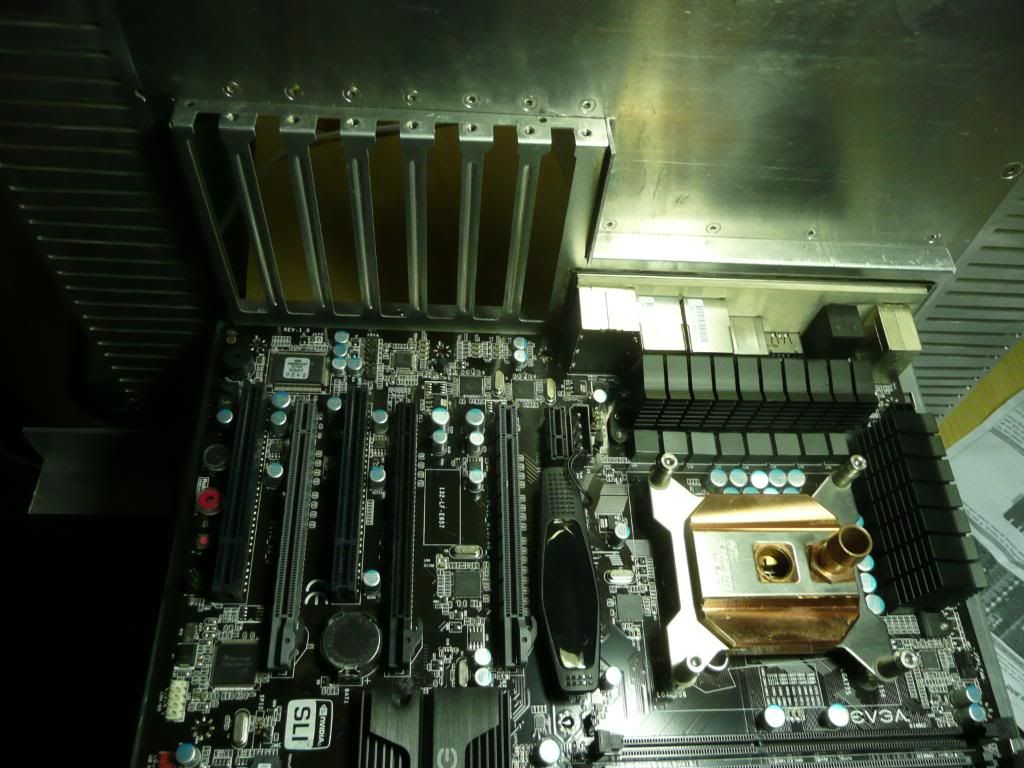

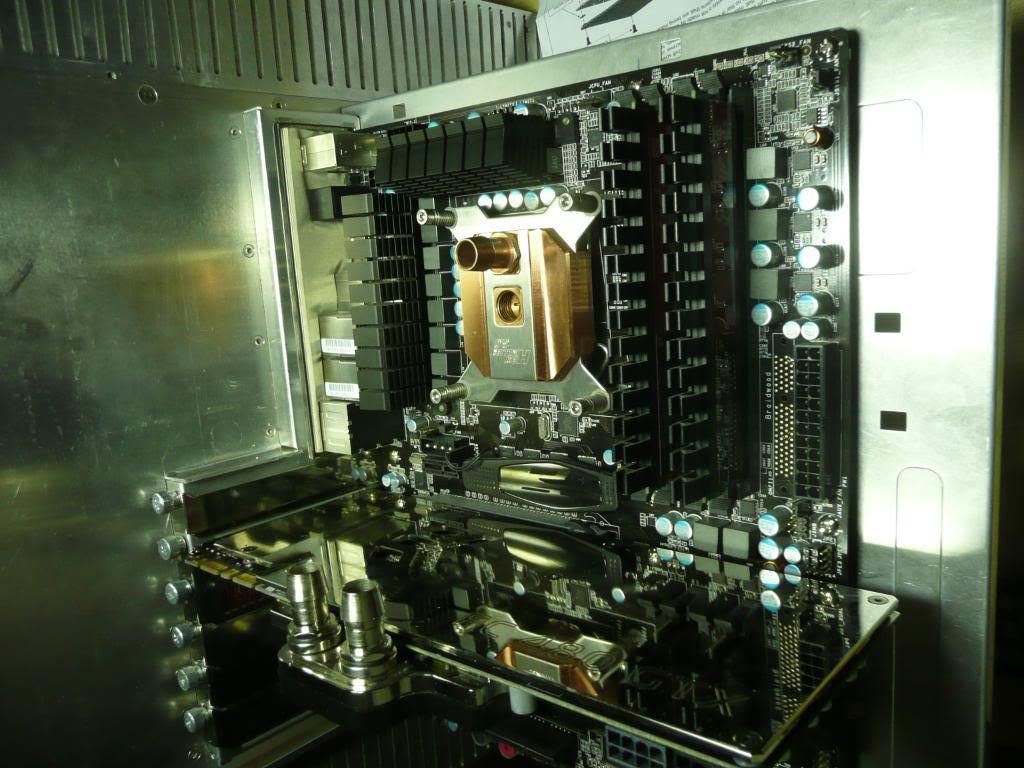

I don't think the heat from the motherboard makes a massive difference tbh. I mean, Mobo cooling blocks are really for aesthetics rather than anything else... I could stick some cardboard around the motherboard, but as the system is designed to run fanless it seems a little pointless as I'm not going to add a fan to cool it! Plus the motherboard etc adds its heat to the water when it is warmest, when it has just entered the radiator..

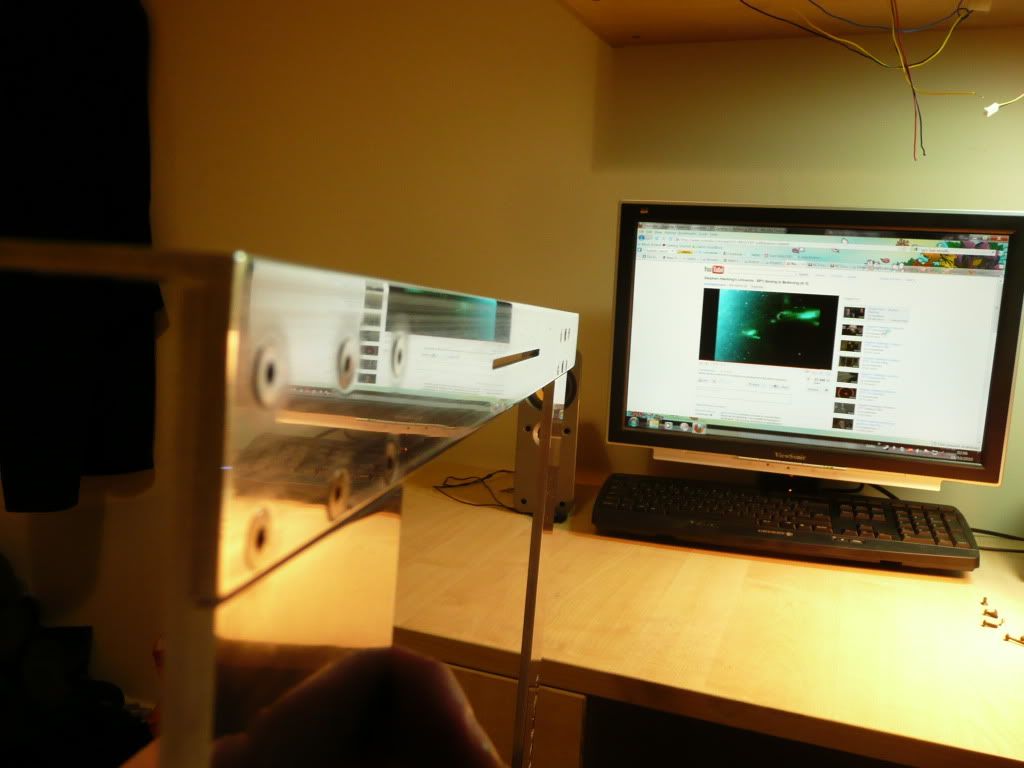

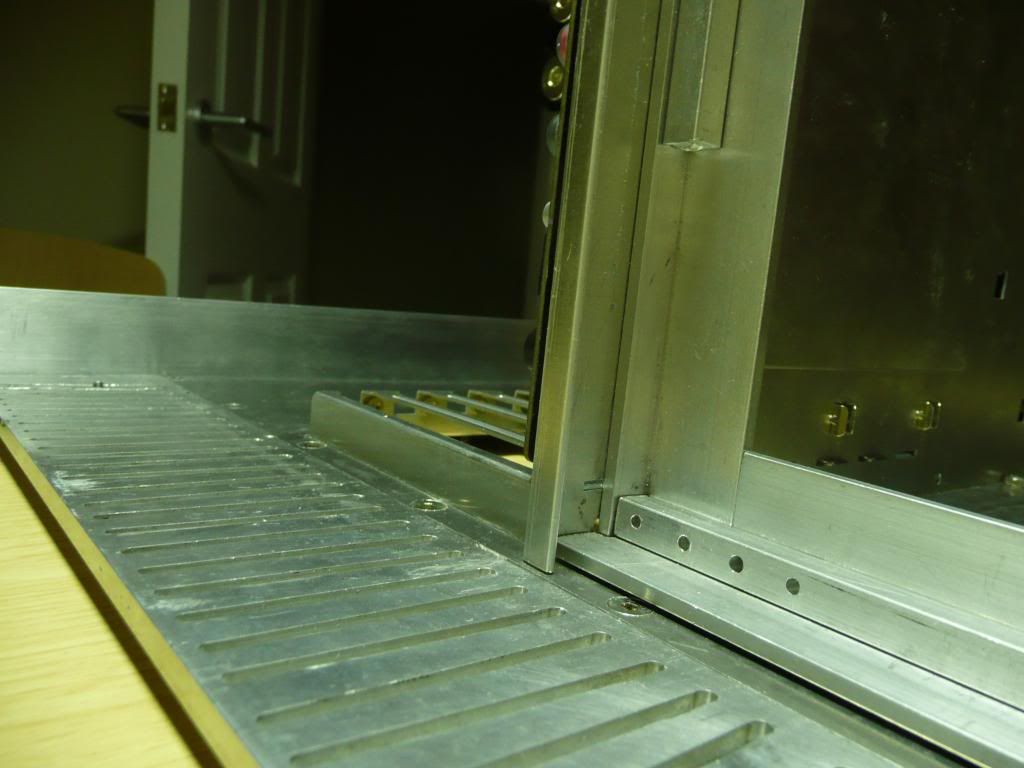

The case is actually designed to make act as a counter-current exchanger with warm water from the loop entering at the top, getting cooled by air that has already warmed slightly and risen through the case, going down the pipes against the flow of rising air, and then going throught the finned pipes at the bottom and being cooled with the coolest air. Of course, more heat would be transferred to the air if no fins were cooled by any slightly warmed air and only received fresh cool air, but that's not possible in this situation due to space limitations. It's a good solution for transferring heat, chemicals etc used widely in biological and industrial processes and systems. Having said that, as nice an idea as it is, I recently plumbed the loop up with the water going first into the bottom and I'm not sure how much difference it actually made to the temps.

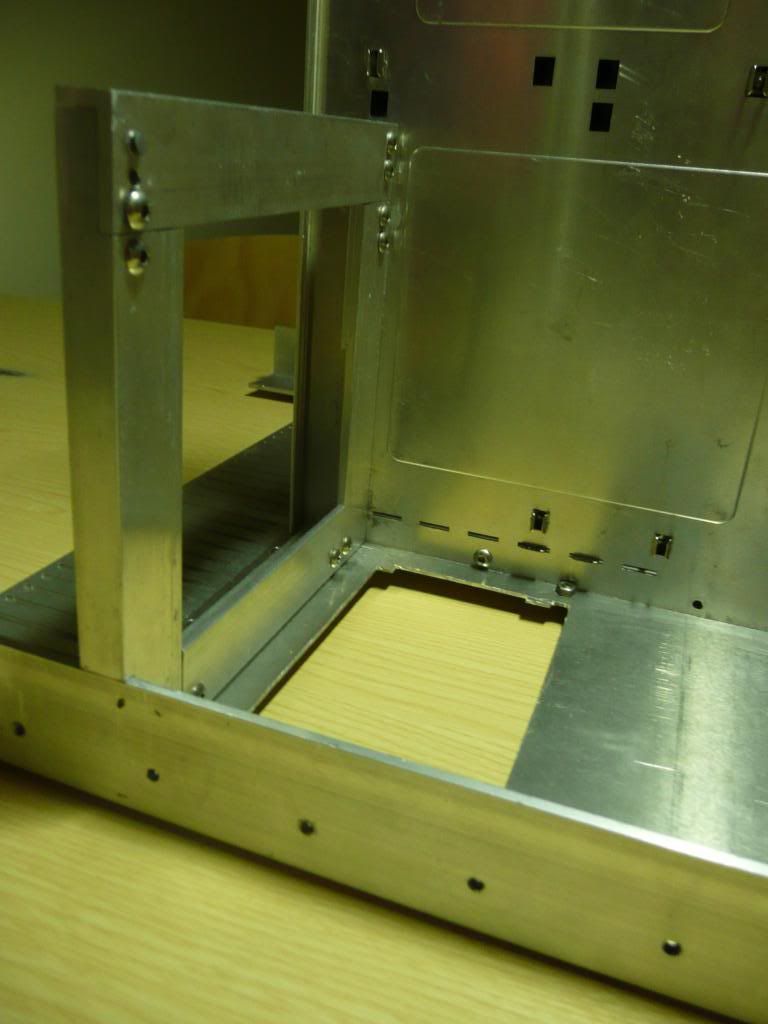

Yep, a lot of hours. But even though tedious in parts (ahem, soldering 4000 joints), I enjoyed making it.

Sort of like people who wax their car. Not much fun, and time-consuming, and that dust and grime isn't actually doing much so what's the point?...

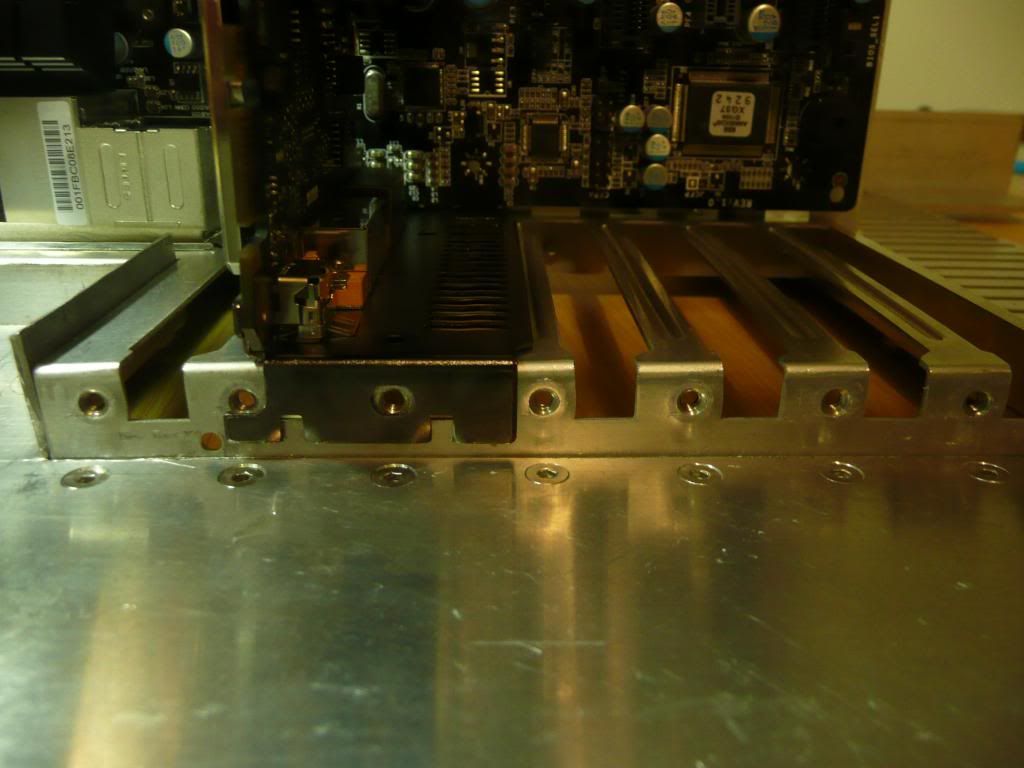

It's not about costing money really. I naively mentioned when I started this project that current passive-cooling tubes like Innovatek Konvekt-o-matik or Cape Cora tubes cost a lot. The reality is that scratch built cases cost a lot in time and materials. Even with getting copper at much less than what the metal is worth as scrap (I paid about £100 for over 25kg of it already cut to strips for me) the project has still cost over £300 I think for raw materials. But people don't make cases to save money over a case off the shelf. They do it because it's a hobby, just as making your own furniture is an expensive hobby compared to buying a set of chairs from a Swedish furniture warehouse.

Yeah, I'm planning to get an aquaero and have temp probes in the water (before and after rad maybe), simple flat probe for ambient and one stuck for heatfin temp to get an idea of water to heatfin delta and see how much heat is likely being dissipated by radiating and how much by conducting.

Yeah, the main problems were from sealing the ends. It's big enough that making molds for sealing the plenums (in polyester resin) and before that keeping bits clamped together for sealing with solder and epoxy is a. Plus I was a litle impatient at times - only recently got it with me and so before that work was restricted to weekends etc. so work did tend to get a bit rushed when I knew I could only get a day or two's work done.

Hmm, never liked the idea of filters. There shouldn't be bits of crap in your loop anyway, so a steel sieve causing massive restriction and getting clogged up seems pointless. Even if there is rubbish in the loop, a microfin block will get clogged up and collect it for removal anyhow.

I'm not an engineer, though I did some basic haemodynamics (basic fluid mechanics) covering Poiseuille's law, laminar and turbulent flow etc. at university a few years back. I just stumbled across EES when looking for freely available modelling software. It's a nice little program, though the numbers are out for my set-up and it doesn't explicitly state how it's modelling and what assumptions it's making, which makes interpreting what it says difficult. That's probably my fault though.I just downloaded the free version; I didn't have any classes or the accompanying textbook to explain it.

Thanks all!

Sadly not - was entered for Bit-tech's MOTM competition back in January at the stage where it was just burnt-flux-covered heatfins soldered to tubes.

Cheers Jay. I don't think the mass of copper's important other than allowing heat to flow throughout it - I'm using 0.9mm thick copper and I'm sure that's massive overkill for ensuring heat is spread easily and evenly throughout the heatfin surface, akin to cabling up an LED with pylon cable.. Commercial watercooling radiators use incredibly thin fins... As it happens those figures happen to be pretty similar to what I calculated though - I have 4.3m^2 of radiative surface area which gives a figure of 630W of purely radiative cooling (for a black painted surface; emissivity 0.95 and with a surface temp of 40C and an ambient of 20C IIRC)... Wish I could find the online heat radiation calculator I was using..

Reply With Quote

Reply With Quote

Bookmarks