I noted this a year and a half ago about how manufaturers should put a focus on mounting hardware and was pleased to see Thermalright efforts in that direction.

http://www.xtremesystems.org/forums/...&postcount=716

I have learned alot from this group on the hardware side as I have not really looked hard at hardware mounting and will be very useful in some sink development I am doing. An odd point here, a manufacturer could not have the best performing sink in a range of sinks but with a good hardware mount design could run the web site review circuit and average out better with good contact and balanced pressure than better performing sinks. I would imagine a best hardware mount should be a priority for the competitive sink market.

As noted the spread on these results run about 9C the difference between a great mount and a marginal one is the difference between a high end sink and an average one.

Taking a repetitive holistic approach. Temp results can range 9C factoring out the heat sink and just considering compound/contact/pressure on it's own.....Non trivial with the whole picture in mind.

Not sure I agree with the convex feature from the contact side of the test resultsFeatures

* All new patented multiple support pressure vault bracket system, allow users adding pressure to the bracket system (40~70 lbs.), and have a more efficient and secure mounting.(1366 / 1156 / 775).

* Mirrored copper base increasingly upgrade the quality and the performance of the heatsink.

* Special bent winglet design, allows hot air to pass the heatsink more rapidly.

* Heatsink are all nickel plated to ensure the best quality and performance and could last for years.

* Soldered heatpipes, copper base and fins, to ensure the best thermal conducting efficiency.

* Six sintered heatpipe design, all heatpipes are nickel plated.To slow the oxidation deterioration to the heatpipe, to ensure longer usage and performance of the heatsink for the cpu.

* Including 2 sets of 120 x 25mm fan clips and Chill factor II thermal paste.

* Convex copper base design, to ensure the Highest thermal conducting thermal efficiency between the cpu and the heatsink.

http://www.xtremesystems.org/forums/...&postcount=716

We have incorporated a new label design on our syringes -tried to add on some racing stripes but they didn't fit

I will be sending out the reformulated Perihelion end of next week, we went through 7 iterations before we were finally satisfied it was stable.

You still have my vote for the best TIM I've used.

Crunch with us, the XS WCG team

The XS WCG team needs your support.

A good project with good goals.

Come join us,get that warm fuzzy feeling that you've done something good for mankind.

I am all Mac now but LittleOwl is my bud and I can test your TIM on my woodcrest to clovertown conversion when I get the fundage if you want to send him some with a ear mark for me.

Got an Xtreme System? Bring it here! <----

I just ran out of AS5 after replacing the factory tim on my H50.

So far, after two days of thermo cycling the new AS5.

AS5 Day3

4 BB sized dots near the inner quadrants.

Corsair H50-Dual fans-flat out.

i5 750@3.6GHz 1.3vid 1.29vtt

LinX-all memory-Load temps at 40 minutes 100% CPU

Idle-36c

Load-72c

The temps should drop a bit after a few more days. This is AS5 after all.

I'll have to get some of this stuff to try.

I excel at Half Ass.

With that application method I would expect it to start to climb again soon. You will have a bunch of air trapped in the spaces between spots.

[SIGPIC][/SIGPIC]

I always apply AS5 that way. I have never gotten Air trapped in there and the pattern looks good. I always check. It hurts nothing to have a look before you screw it down.

There is not that much space between the dots. Usually none at all. It's fine. I don't think I will use that method when I get the IC diamond TIM.

I excel at Half Ass.

Wait ... you put it together and then separate the interface again before you screw it down? Seriously???

[SIGPIC][/SIGPIC]

go to ic diamond website and actually look at the slides with the different application methods... you would be surprised how the air bubbles actually do get in there

and, yes, it DOES hurt to have a look after you apply it and then put it back

Main: i7-930 @ 2.8GHz HT on; 1x GIGABYTE GTX 660 Ti OC 100% GPUGrid

2nd: i7-920 @ 2.66GHz HT off; 1x EVGA GTX 650 Ti SSC 100% GPUGrid

3rd: i7-3770k @ 3.6GHz HT on, 3 threads GPUGrid CPU; 2x GIGABYTE GTX 660 Ti OC 100% GPUGrid

Part-time: FX-4100 @ 3.6GHz, 2 threads GPUGrid CPU; 1x EVGA GTX 650 100% GPUGrid

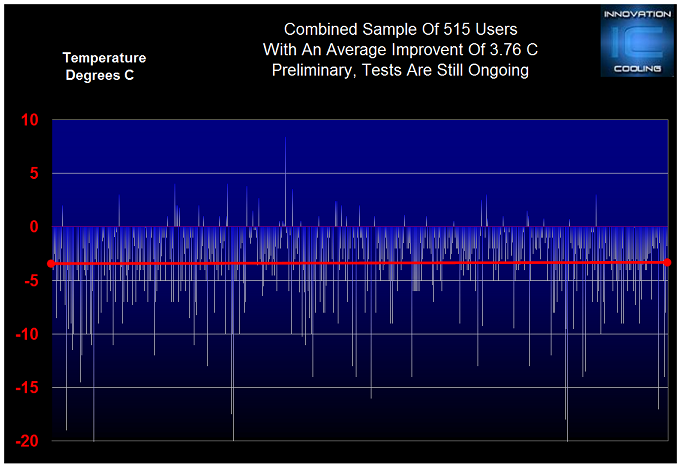

Updating my charts this weekend and hit the 500+ user tests milestone. Raw data chart, haven't broken out he individual competition compounds yet, getting a little crowded

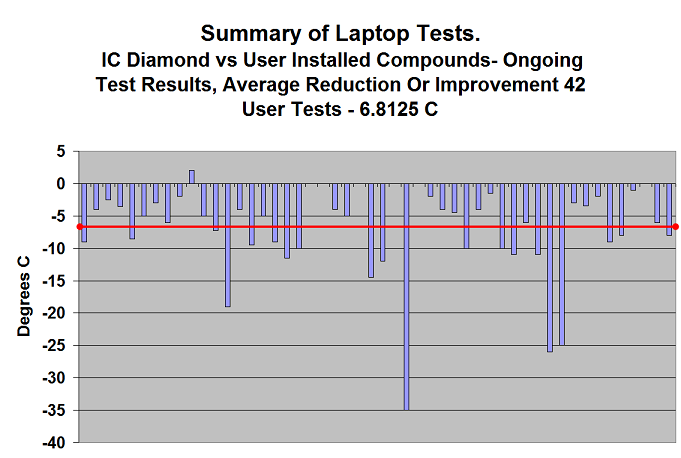

Lots of notebook people on the re-paste track these days

http://forum.notebookreview.com/asus...success-2.html

From my post at notebookreview

In any event below chart is not final as all results are lumped together, GPU/CPU will be broken out on final.

What is interesting is I would categorize any improvements 10 C and over as catastrophic failure of the stock compound. I count 12 out of 42 roughly 25%

That's a real high number vs the standard PC which are more like 1-2%.

This would translate to early component failure, reduced life expectancy, increased returns/costs of owning a laptop etc.

I must admit that I have been a slacker when it came time to test the newest paste. I had tried MX-2 on the i7 920 that I got for Krunching and my temps were very high even after a re-mount. I am now using the 24c paste and my temps after cure-in time have lowered considerably.

I always had great success with 7carat but the new paste is even better, great job!

XSWCG Disclaimer:

We are not responsible for the large sums of money that you WILL want to spend to upgrade and add additional equipment. This is an addiction and the forum takes no responsibility morally or financially for the equipment and therapy cost. Thank you and have a great day.

Sigmund Freud said... "Failure to CRUNCH is a sign of Sexual Inadequacies".

I've been using the Diamond i7 since Mr.Tastymannatees first came to XS.

Always been happy with it and now you tell me they have a better one?

Crunch with us, the XS WCG team

The XS WCG team needs your support.

A good project with good goals.

Come join us,get that warm fuzzy feeling that you've done something good for mankind.

.....and there was me thinking that the difference between ic7 and ic 24 was the tube size.....

My Biggest Fear Is When I die, My Wife Sells All My Stuff For What I Told Her I Paid For It.79 SB threads and 32 IB Threads across 4 rigs 111 threads Crunching!!

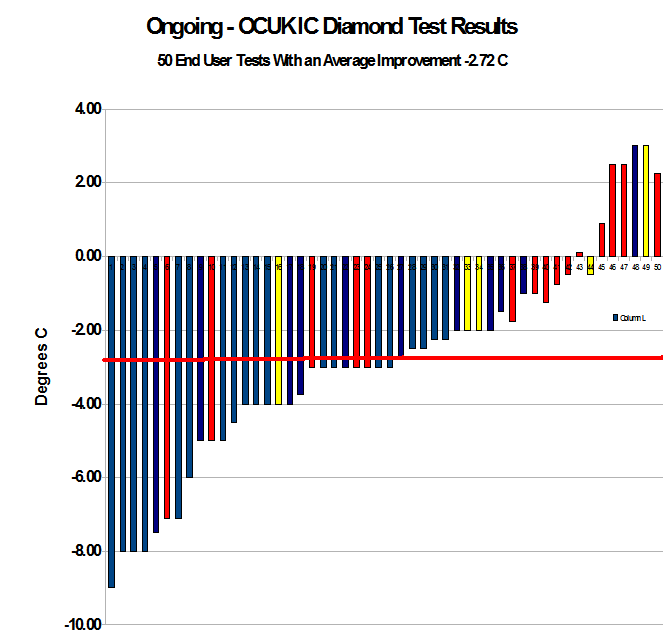

You people were the 2nd group survey we did and and a lot of good stuff came out of it. So now at 20 giveaways the most recent from OCUK

This set of data that separates OCUK from all the 20 or so groups tested by us.

In the past water cooling is usually less than 5% of the sampled results, on OCUK at this point we are 30% water cooling(marked in red), 70% air.

What made it readily obvious was the statistical cluster of 20% water in the marginal-zero-negative result category. The other 10% is mostly the H50 in the performed as expected group. Might be linked to compound mix but I have a sense that it may have an overall edge in C/P for the H50.

In any event The air cooler group (marked blue) has it over the water with pretty much positive results across the board.

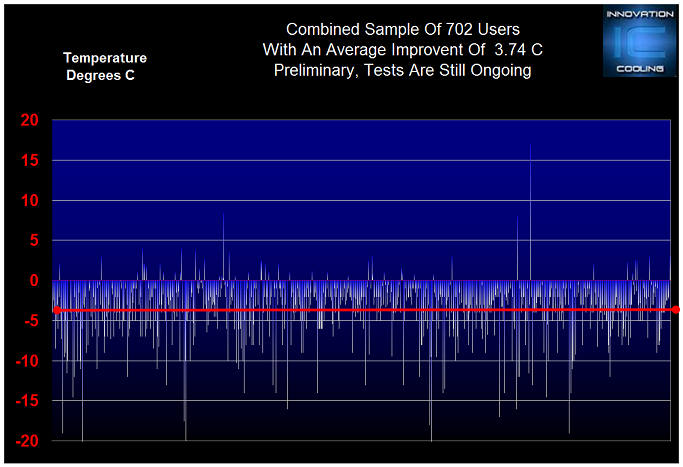

hit 700 milestone you guys were in the first 100 or so

Just started using this on my GPUs for LN2. Very nice paste! Just requires heating the pot up a bit to thin out the material before dropping temps

Way to go with subZero

My man in the UK gilagamesh at overclockerstech uses a hairdryer otherwise you could cold cure.

I ran a test with a couple of glass slides, some binder clips (60 psi)and a micrometer.

After about 2 hours it was 95% of bond line thickness (BLT) overnight 98%

You can not just slap it on and go directly to zero paste will harden before before BLT is optimum.

Improve your numbers? How much?

We have been doing a IC Diamond Reliability Survey over at Notebook Review with some interesting results, although only halfway through the survey a major factor in long term reliability relates to Contact and Pressure as we went through the process here with C/P and performance same applies to long term use.

When you have full contact with thermal and mechanical loads in sync with each other fully/evenly distributed across the entire processor and would be a likely canidate for long term use.

Just some quick notes

Looking at the data to date it looks to be trending that if you hit a year with no change you are probably clear for extended 1.5- 2- 3 year use. A temp rise above +5C within the first year is a pretty good indicator that you will hit + 20C by year 2.

A kind of a go- no go indicator, those that hit in the 20C range I would call a failure and would repaste and while you have the system apart consider lapping the sink or some mod as TanWare's to improve contact. To note I have a couple of retailers that have agreed to test market the Contact and Pressure indicating film and should retail around $5-$8. Note that we are not selling the product and will not profit from it, we are only promoting it's general use for end users as a tool for improving performance/reliability

I am assuming a 5C +/- error on these tests as most are sloppy about reporting ambients.

As noted in my previous post there does not appear to be any correlation yet as to higher initial temps leading to a failure. Technos started with an initial temp of 58 C and at close to the one year mark ended up 19.25 C while Karamazovmm whose initial temp was 95C ended the year at 90C basically unchanged. There are other examples but this happens to be one of the more extreme. This was a suprise to me as typically notebooks runan average of 15C higher than the overclocked systems so I was expecting some indication in that direction at this point perhaps needs more time.

Applied thermal compound is simple stuff as things go, two mating surfaces with some goop in between and there are not too many avenues to explore to explain a difference in results other than amount of compound applied (we assume everbody gets this one right) Then the contact and pressure between the two joining surfaces.

As we discovered with the C/P testing the weak point in this simple setup is in the contact and is a reasonble cause for good result or bad result or something in between.

Note below yknyong1 contact area being worst case most of the heat transfer would be in the corner/edge area, a significat heat concentration more like a soldering Iron this edge corner/area would be the part of the joint to fail first and as the remaing paste is lightly contacted would then run at higher temps baking out initially then delaminating with further thermal cycling. This kind of contact is a likely canidate for early failure

The following BlazeSempai example at the other end is full contact with thermal and mechanical loads in sync with each other fully/evenly distributed across the entire processor and would be a likely canidate for long term use.

This is as simple as it gets.

yknyong1- Apple Macbook Air13 i5

BlazeSempai p 8700

From the testing I did with this I can say that you need a bowed heatsink or waterblock on 1155 and a less bowed version on 2011.

The reason being that the edges of the ihs are invariably higher than the center and it is the center that needs the contact most.

The normal springs one gets in a water block kit could do with being upgraded for stronger ones or if you feel you want to really get good contact pressure maybe consider torquing the nuts down onto bound springs.

My Biggest Fear Is When I die, My Wife Sells All My Stuff For What I Told Her I Paid For It.79 SB threads and 32 IB Threads across 4 rigs 111 threads Crunching!!

interesting results, any testing with 3rd party air/water cooled gpu's?

All along the watchtower the watchmen watch the eternal return.

Bookmarks