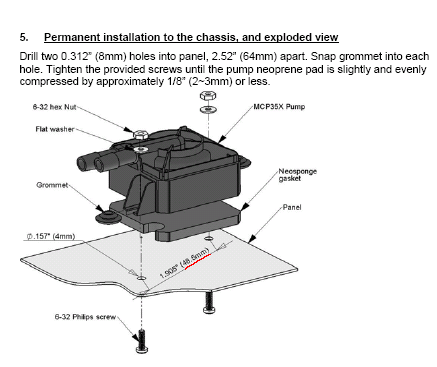

I am drafting a design for a DDC stand that I am going to make out of acrylic. I have gone to the Swiftech website and found the installation guide for some measurements. There is something that doesnt make sense to me, maybe you can help.

Description says 8mm holes 64mm apart. Diagram depicts 4mm holes 48.8mm apart.

Are these contradictory or am I reading this wrong?

I do not have the pump in front of me, and had planned on fabricating the stand at work today, so quick replies are appreciated!

Reply With Quote

Reply With Quote

Bookmarks