Farm-09 Q6600 on an IP35 Pro. "Edge lap" before and after. All with D7 paste.

Refer also to my posts #202 and #417 for more info on this same machine. I'll try to provide the full story here, but who knows......it's been a long week already!

I'll hold my temp data until the end of the post so it's all together.

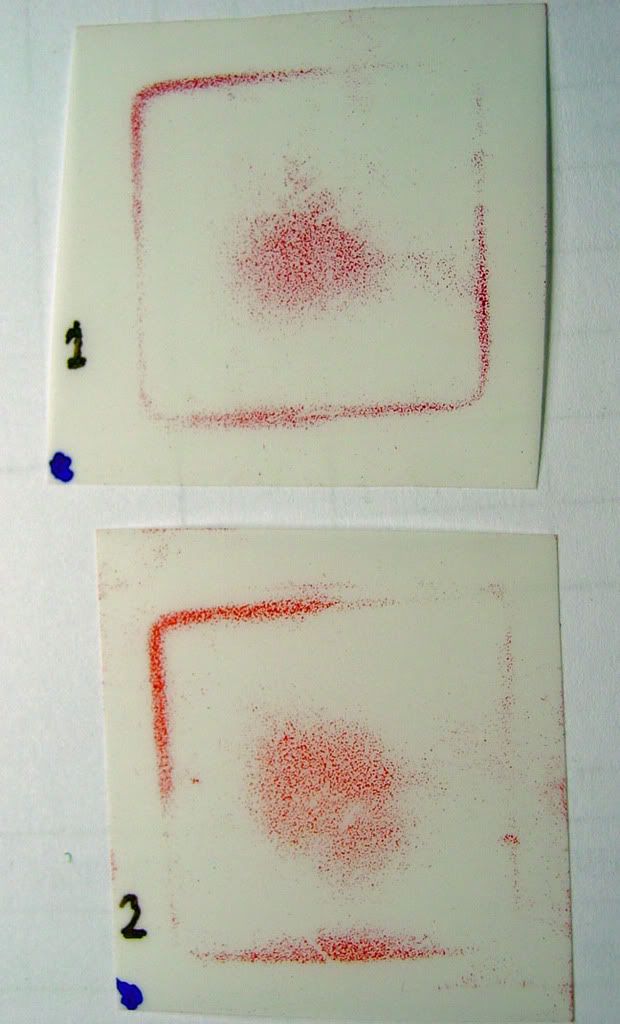

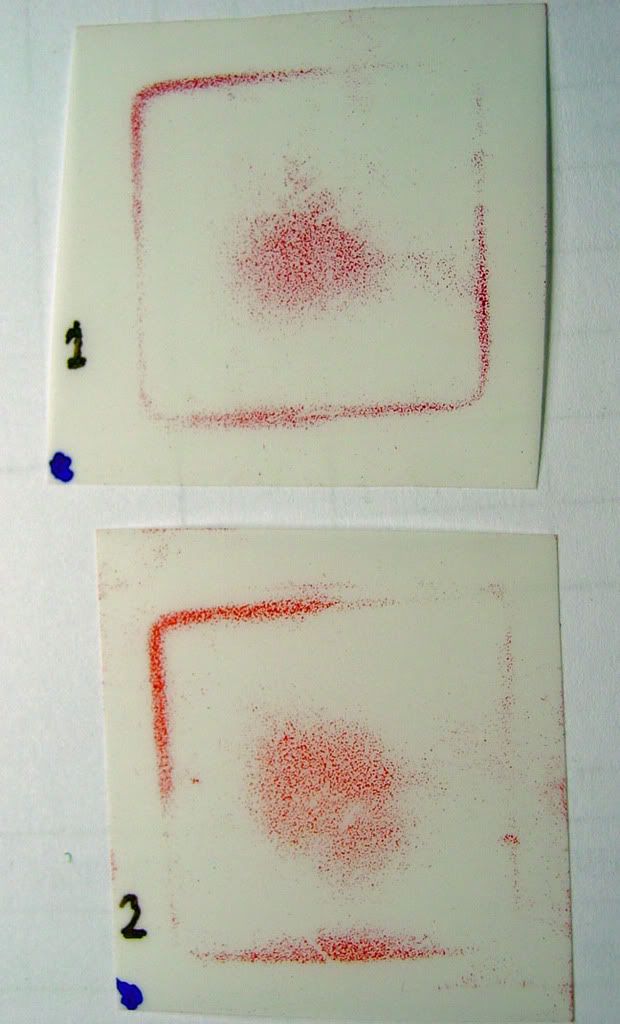

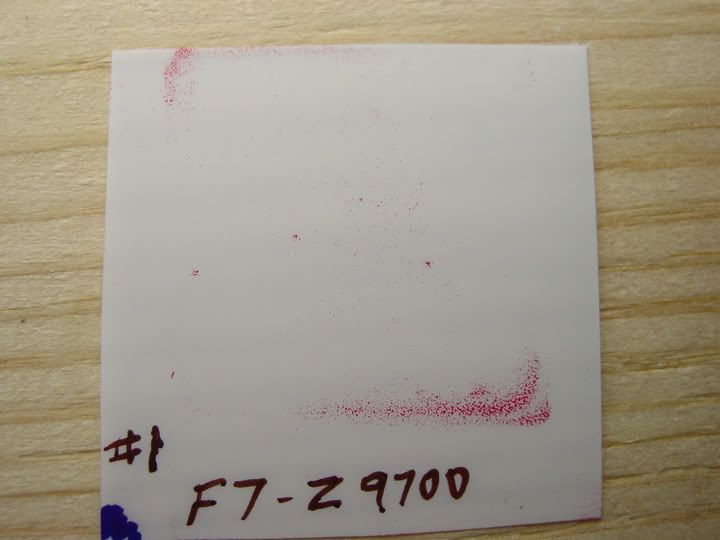

Here was the original pressure test films from before, out of post #417. It was pretty clear that this quad had the "island, moat, high edge" that most quad IHS's show.

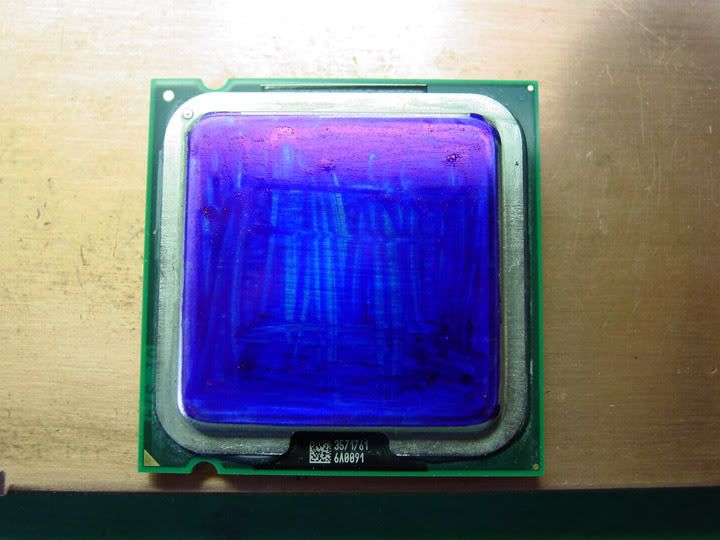

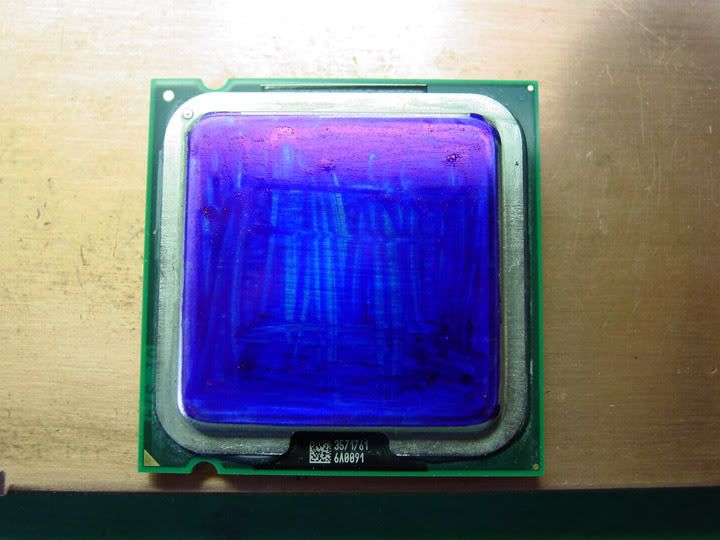

I blued up the CPU with "poor man's" Dykem blue, a blue sharpy marker. (Dykem blue is something gunsmiths use to check contacts. SiG and SS probably know about this...)

I took a few flat strokes on the 1/2 solid copper bar I use to lap. (This thing is dead flat as shown by using a high grade machinists rule, and holding it up to bright light.) I did this to see the intial profile better. The same rule on the CPU showed that it indeed had the "island, moat, edge" profile, as shown by one of Tasty's diagrams. Where the blue is gone is where the high spots are.

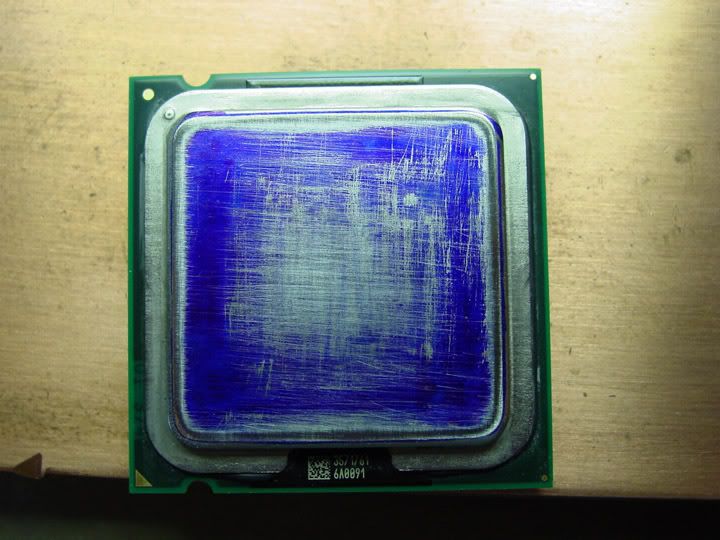

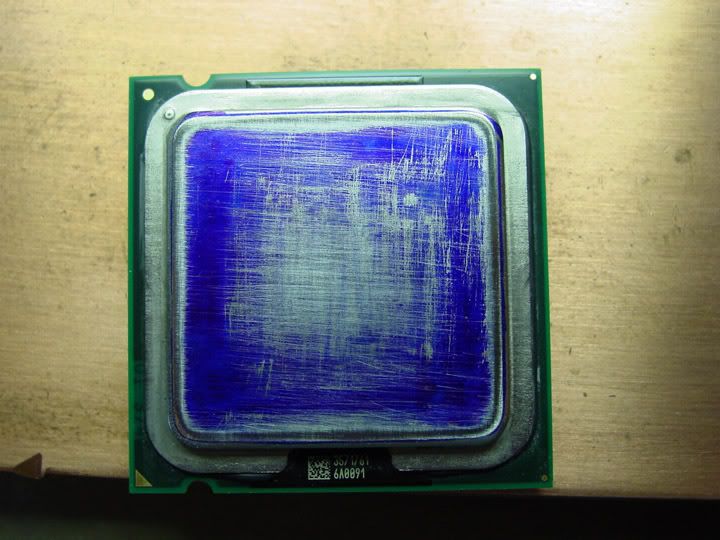

So, I went about figuring out how best to take down the edges since I had the high spot profile. I re-blued the thing to get another baseline and took the CPU by the edges with a slight tilt to the copper bar. I worked a few strokes at a time and rotated the CPU to the next edge. The tricky part was getting it even. I actually think it's easier to lap flat than to try this technique. But hey, this is science, right?

Here is a pic after the rough edge lap. Note that it has the reverse of blue color left on it than the first profile pic.

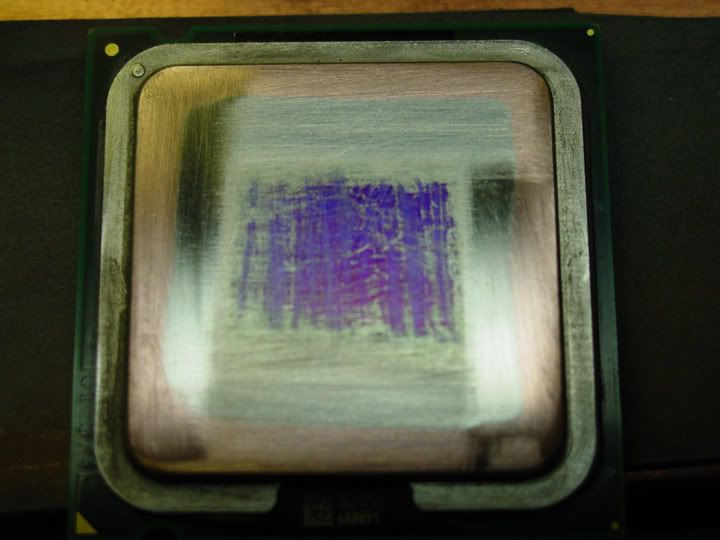

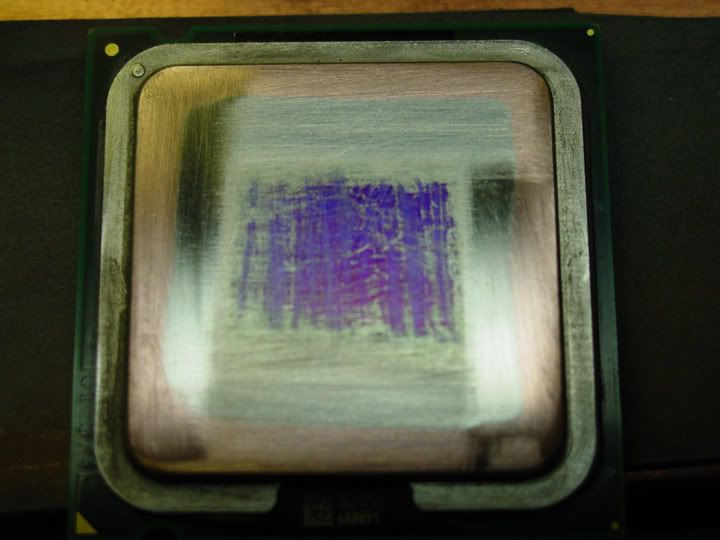

Of course, no self respecting lap job can go without finer grits and polishing. A good lap job is one where the camera takes a picture of itself, out of it's own vanity...

I had to try it, so I used D7 as the polish. (What the heck, I already tasted the stuff, it tasted like it would be good polish...

) It worked quite well...as you would expect out of diamond compound.

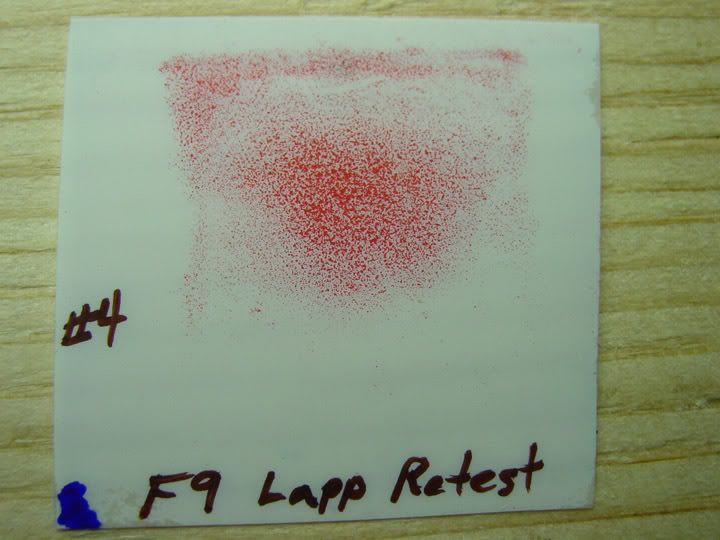

So, the next test was to see the difference in the pressure test. Comments after the pic.

I thought it was a curious result. I may break it down and try it again. I don't know what's up with the diagonal white line down the left of the middle, or the white spot in the lower center. Does the film perhaps have a dead spot in it? It definitely has a bias to the front of the CPU. I'm also curious now what a flat lap would show.

Looking with the machinist ruler, at a bright light, the TRUE is slightly convex, and this CPU is now a bit convex. I would have expected a solid patch in the middle. I'm doubting now that the TRUE spring screws put consistent pressure all the way around the mount. The order that I've put in the screws has been the same in all testing on this machine. Lower left first, then upper right, then lower right, then upper left. Maybe this result makes sense with that pattern.

OK, now to temps.

Before Lap - D7 paste.

Ambient 20.3

CT idle 24,26,24,24

CT load 40,44,38,40

After Lap - D7 paste.

Ambient 17.5

CT idle 21,22,19,19

CT load 37,40,35,36

Ambient delta of 2.8 degrees C. Picked up some improvement on idle, picked up only a little improvement at load. I'm not sure what to make of this other than to try another film on this setup, then lap flat, film it again and re-run temps. Tasty, let me know your thoughts. I would not be against lapping both sides on this to see what happens....

Another thought. I'm beginning to wonder how linear the CPU temp diodes, and/or Coretemp is performing. I will attempt to better control my ambient variation when I take test points.

Regards,

Bob

Reply With Quote

Reply With Quote

Here is a pic after the rough edge lap. Note that it has the reverse of blue color left on it than the first profile pic.

Here is a pic after the rough edge lap. Note that it has the reverse of blue color left on it than the first profile pic.

I had to try it, so I used D7 as the polish. (What the heck, I already tasted the stuff, it tasted like it would be good polish...

I had to try it, so I used D7 as the polish. (What the heck, I already tasted the stuff, it tasted like it would be good polish... ) It worked quite well...as you would expect out of diamond compound.

) It worked quite well...as you would expect out of diamond compound.

The contact areas become voids? Maybe we should be sandblasting the IHS Instead?

The contact areas become voids? Maybe we should be sandblasting the IHS Instead?

The X3350 was nice, but I need those Nehalems to start showing up...

The X3350 was nice, but I need those Nehalems to start showing up... )

)

Bookmarks