some notes from last night's testing at high FSB for 3D stability

first of all............if i get a 32M SuperPi run i should be 3D stable as well ...very good indication

actually using AM3 is probably quickest way to find out

now the settings....didn't take me long to get to this but there is a fair bit of trial and error and with subsequent testing i realised these settings are sweet spots atm

here are the volts set in bios which gave me the highest stable FSB i could benchmark with (595MHz)

Under System Voltages Section:

CPU Core >> set value required for MHz OC

CPU FSB >> 1.45v

Memory >> set to value required for MHz OC (1.9-2v is plenty for 2GHz speeds and decent timings)

Nforce SPP (NB) >> 1.45v (VERY important) going lower or higher reduced stability > higher probably due to possible better cooling required (will have to test that but NB is generally pretty cool

Nforce MCP (SB) >> 1.75v (PUT A FAN ON SB)

LEAVE GTL REF at AUTO >> system will determine the best settings (-80 for me at high FSB) >> for stability at ultra high FSB you can also try dropping it to -90 to -110otherwise leave it at auto

Note in RAM settings there are two settings called P1 and P2 which require you to increase volts manually or you will corrupt your windows as the chipset latencies are set very tight particularly when both P1 & P2 are enabled. For high FSB testing i could not boot even at 575MHz FSB with both P1 and P2 enabled (probably would work with better cooling on NB and possibly some more volts). I had P2 enabled for my 3DMARK runs which i was very happy with

RAM Settings >> i normally set main timings 8-7-6-20 1T and rest are left at auto which i tune through memset

Reply With Quote

Reply With Quote

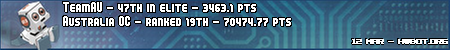

(4th fastest run on HWBOT)

(4th fastest run on HWBOT)

now crank the CPU clock to 5400Mhz

now crank the CPU clock to 5400Mhz

Yes, Yellowbeard, a tall rough man with a big yellow beard

Yes, Yellowbeard, a tall rough man with a big yellow beard

(great allrounders those coolers)

(great allrounders those coolers)

Bookmarks