Hi guys! finally got to modifying a back plate to stop the bowing of the motherboards when using convex based cpu water blocks such as the new D-tek Fuzion block and Swiftech Apogee GT. This mod would work and should be done on any motherboard using 775 Intel chips and a cpu water block that does not come with a back plate.

This idea came about after reading about the swiftech challenge and what happened to the guys the first night when they broke the EVGA 680i mother board from installing the new convex style bases of the cpu water blocks. After my install experience of a Dtek Fuzion block on another thread several members suggested why cant we modify a back plate to stop the motherboard from bowing?

http://www.xtremesystems.org/forums/...d.php?t=131298

Virtualrain posted this link http://www.thermalright.com/a_page/m...ion_lga775.htm

as a good back plate. The part itself only costs 5 dollars MSRP shipping will cost more then the part.

http://www.newegg.com/Product/Produc...82E16835999351

Why cant the water block companies supply us with this? Since the Dtek and Swiftech Apogee GT are so close in performance the first company that would supply a back plate would surely take the most orders from us dont you think?

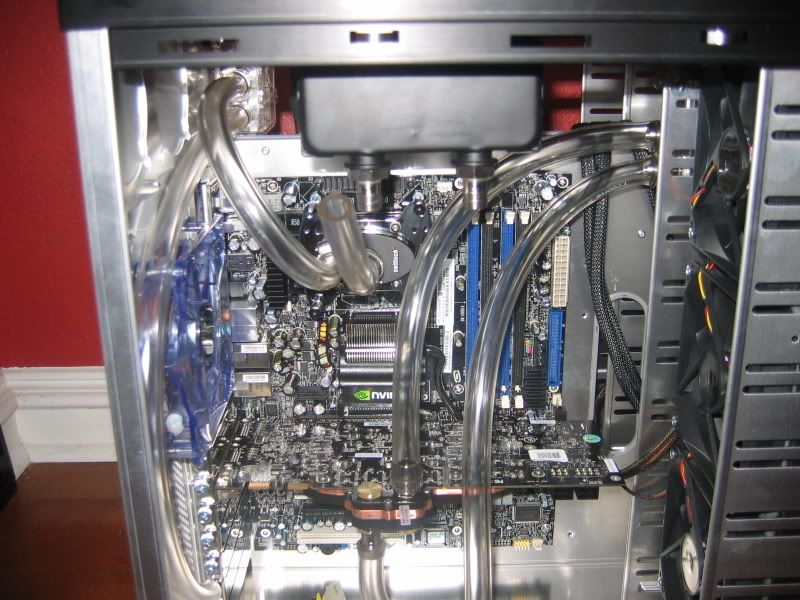

Lucky for me I had a brand new one sitting in my computer closet so I modified it to work with the studs from Dtek Fuzion block. I took a 9/64 drill bit and enlarged the holes and added double sided sticky tape since it has a foam in it as a cushion on all four arms of that back plate. This protects the resistors on the back of the EVGA 680i board from being smashed by the pressure of the Waterblock tension. As you well see in the following pics the motherboard after the backing plate install would not bend even up to 15 full rotations of the tension screws where as before it would bow after five full rotations of the screws. This will help in applying even consistent pressure on the cpu giving more even temps across all cores and protect the motherboard.

Without the back plate and new Fuzion waterblock you see the board has bowed after only turning the screws five full rotations. Notice the heat sink has seperated from those heat producing chips that can cause bsods when over heated.

without back plate

here are pics of the back plate installed and turned 15 full rotations till almost hitting the spring stop which could not be done before. I didnt want to push my luck and crush the bottom side resistor so I left the screws hand tight and snug. Red circle is the resistor and the white foam is the extra double sided sticky tape as a cushion. The resistor is to the side of that steel arm of the back plate but I padded it anyways.

I also noted that taking off the original mount and looking at the thermal paste distribution without the backing plate showed the contact of the Fuzion block was dead on center with untouched thermal grease to the sides. After the backing plate almost all of the surface area of the cpu was being used with more pressure seen in the middle of the chip.

Here are some preliminary temps before and after the backplate install. Remember AS5 has not cured yet so the temps are still little high but not bad notice how the cores are more close to each other in temps after the back plate install. My computer room is always 77-78F as measured by a digital therm in my room and thermostat that controls that room.

here is before install at idle

Here is before install under load

After install 1 hour idling

after install 1 hour load

Reply With Quote

Reply With Quote

....

....

Just ordered a couple from Best Byte Computers. Should be here tomorrow.

Just ordered a couple from Best Byte Computers. Should be here tomorrow.

Bookmarks