go around the IHS with the razor blade... some cpu's have resistor banks (like my 805) so only go in around .5cm... you just want to get the RVT silicone off

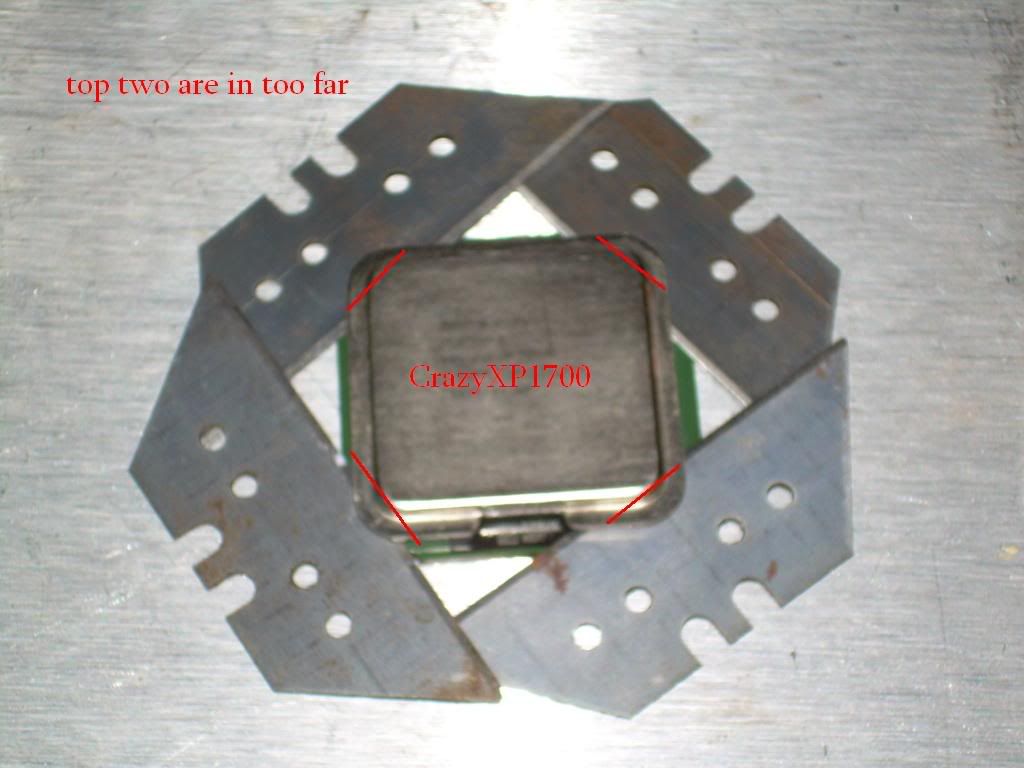

Put a razorblade in all 4 corners of the IHS...

now this is going to be used to do 2 things

1. it's going to suspend the PCB so that it will drop right out once the solder reaches it's melting point..

2. the razors are actually going to be applying all the pressure that you need to seporate the IHS from the PCB... so you shouldn't have to twist or apply any pressure to it... once it's warmed up... all the presure is just gonna shoot that CPU down... and the razors should be holding up the IHS still

place the razors holding the CPU over a vice, or something so the cpu can drop freely... now you'll want to put some foam or something like that below because it will literally POP off!

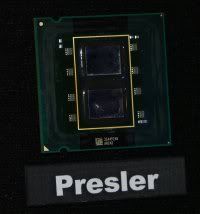

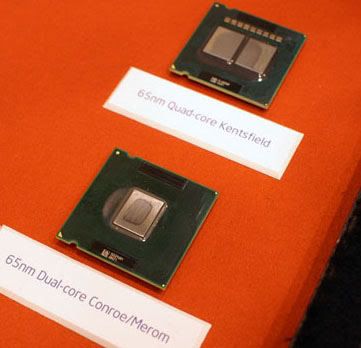

Core 2 duo's may be a little tricky... basically you've got a couple of these you've got to pop... i think warming up faster would be the best option... that way one core doesn't pop before the other... circular motions around the IHS would be the most ideal, the heat should transfer throughout... but still a fration of a second later could send one core popping off while the other is still firmly attached... (i havn't done one yet!)

I used a big ass propane torch, a fire maker, 4 razor blades, and a CPU to risk!

Reply With Quote

Reply With Quote

)

)

but it was dead before I removed the IHS. I have tested it in a friends 925x board and had no go and 45 code still. Also you can remove the solder with your finger nail as crazyxp said so that's one problem solved. I'm trying to get another celery now and I will try again

but it was dead before I removed the IHS. I have tested it in a friends 925x board and had no go and 45 code still. Also you can remove the solder with your finger nail as crazyxp said so that's one problem solved. I'm trying to get another celery now and I will try again

Bookmarks