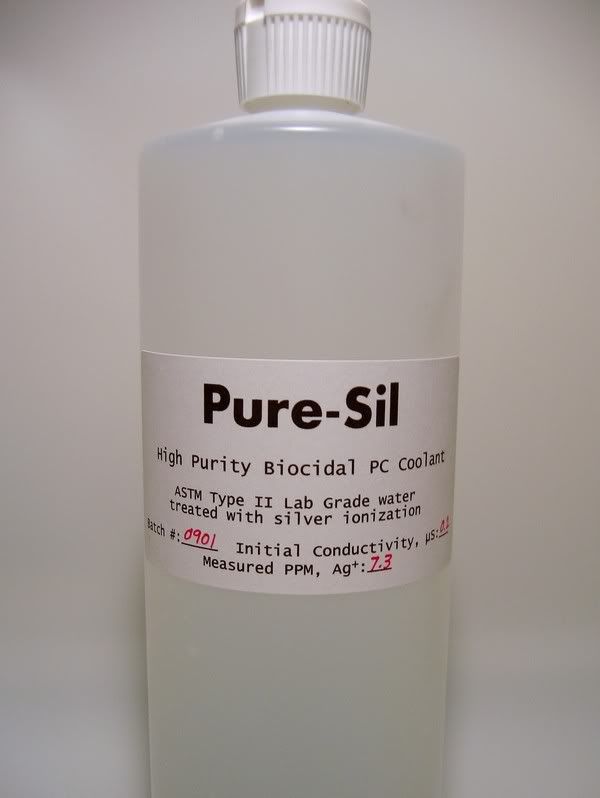

Been working on this the last few weeks, first batch should be at Petra's on Tuesday.

The only available size atm is 32oz. in a flip-top cylindrical bottle, I'm not sure of the exact sale price yet but it will be priced comparably to other coolant products.

I make NO claim that this coolant is "superior" to plain old, high quality distilled water. The only claims I make are that it has a guaranteed purity, and has a guaranteed silver ion content (which gives it biocidal properties).

The problem with store bought distilled is that you never really know what you are getting unless you measure its conductivity yourself with a properly calibrated meter. Good quality distilled or deionized water should have a conductivity of <1ÁS. As an experiment I purchased every brand of distilled water I could find earlier this week. I tested them all, and the worst of the bunch was 22.5ÁS. That is HORRID quality for steam distilled water, and while not exactly incredibly dirty, it isn't exactly pure either. Most of them were under 2ÁS, although the second worst at around 11ÁS was a name brand.

I talked to a guy who said he personally has measured store-bought distilled as bad as 86ÁS... that is BAD. He called the manufacturer and alerted them, the next batch was down to 25ÁS, he called once more and the batch after that was finally at spec (<1ÁS).

The water I use for this coolant is lab grade water purchased from a chemical supplier. Once again, there is no claim it is "better" than good quality distilled, but at least I know EXACTLY what I am selling to people, and they know EXACTLY what they are getting, unlike buying store bought distilled and not having a clue whether it is actually pure or not unless it is tested.

The water used in each batch is tested for purity once I recieve it. My test meter is calibrated using a factory supplied calibration solution each time. Each and every bottle is ionized and tested for ion content individually. The measured ion content, initial purity, and batch number are then handwritten on the label as seen. It takes about two hours per bottle (32oz.) to produce. This is so that I can keep the non-ionic silver particle level small. It also ensures that I am forming a high purity silver solution, cranking the juice can cause all kinds of nasty unwanted silver compounds to be formed... that would mean an unsafe and low quality product.

This coolant combined with copper ions shed by the blocks in a loop creates Copper-Silver ionization, which is death to just about any known single celled organism that can grow in a loop.

I make the silver ion content MUCH higher than is necessary, so the biocidal properties of this coolant should last for a very long time as long as the loop is cleaned properly before filling (silver ions will bond to loop contaminants). Luckily about 5-10% of the silver content of this coolant is made of neutrally charged atomic clusters (aka colloids), so no matter what, there always will be some silver present, even in an amazingly dirty loop.

Using additional silver such as an ingot or coil is not necessary, but recommended for those who plan on running long-life loops, and the solution will drop ions over time both through slow action with the loop, and through interaction with any biological agents that attempt to grow.

As far as safety goes, none of the particles are larger than water molecules, so they should have no effect whatsoever on pump bearings. The coolant is non toxic and safe to drink, even in larger quantities, although it may give you a slightly upset stomach due to the silver wiping out friendly bacteria in your gut. If someone does drink it, eating a cup of yogurt is the only treatment needed.

Reply With Quote

Reply With Quote

Bookmarks