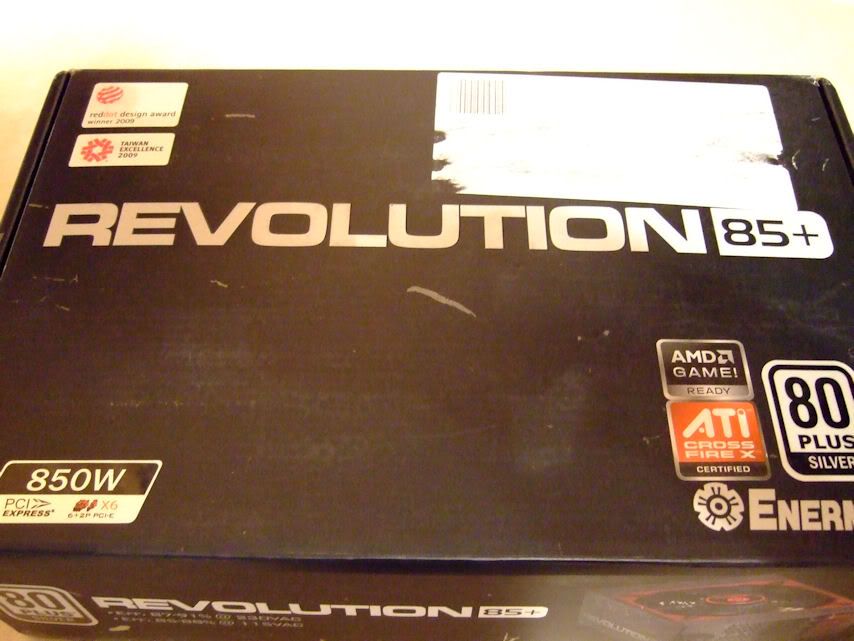

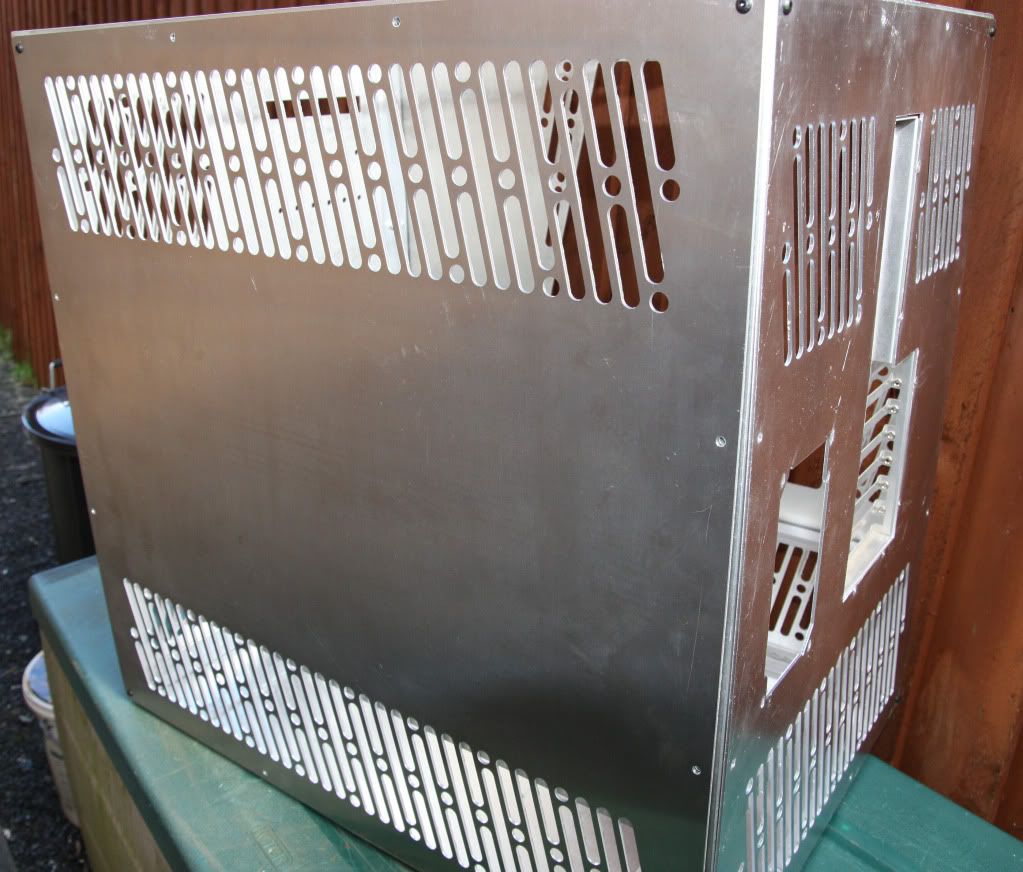

Instead of invalidating the warranty on my PSU, I have purchased some extension cables from Tom.

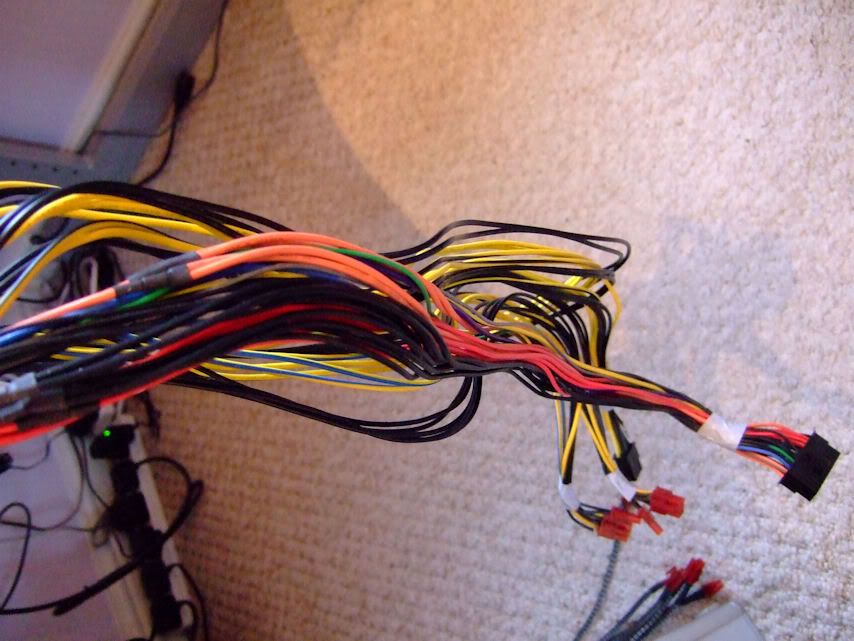

I purchased a few braided and non braided cabled. I decided to braid them all in Tom's Dense Weave braid.

First up the 8 pin ATX connection

Also purchased some 2.5mm Dense Weave cable braid & heat shrink.

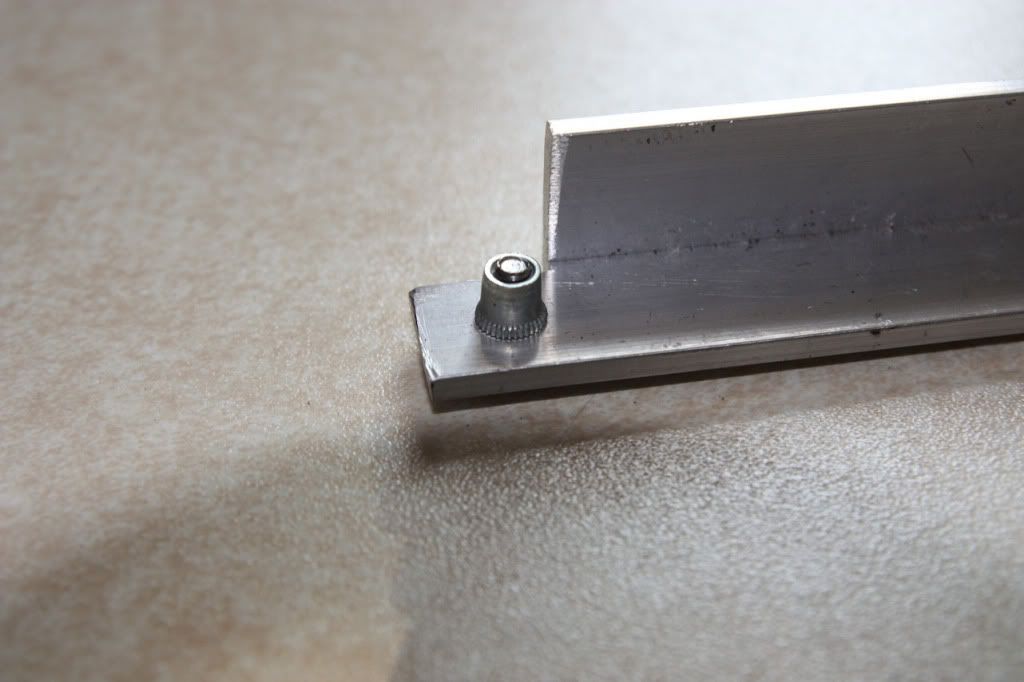

Purchased a new pair of pliers and side cutters from the local pound shop (no expense spared)

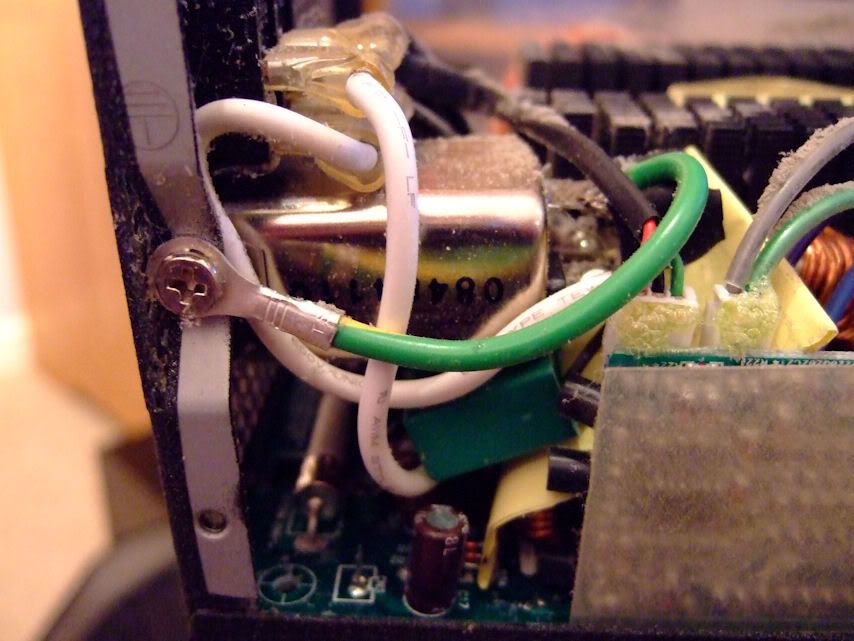

Cut the original braiding off to expose the cable and connections.

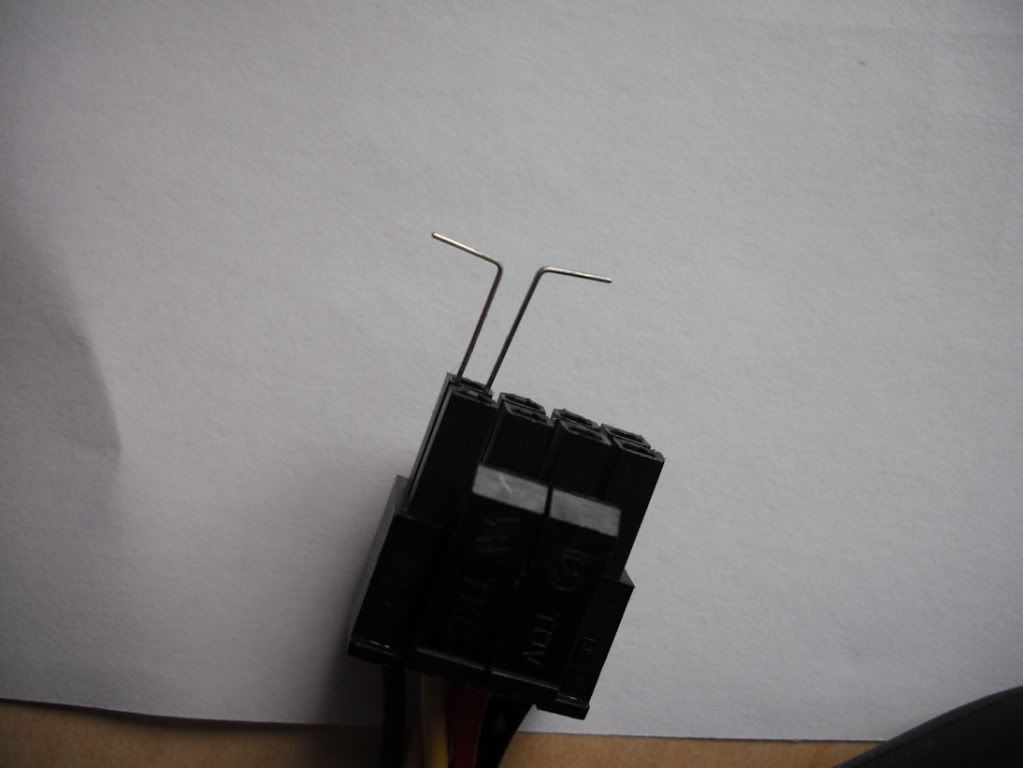

Then used a few paper stables to release the pins

As you can see, the clips are straightened and pushed down the side of the connector to release the pins.

After a little bit of time, finished

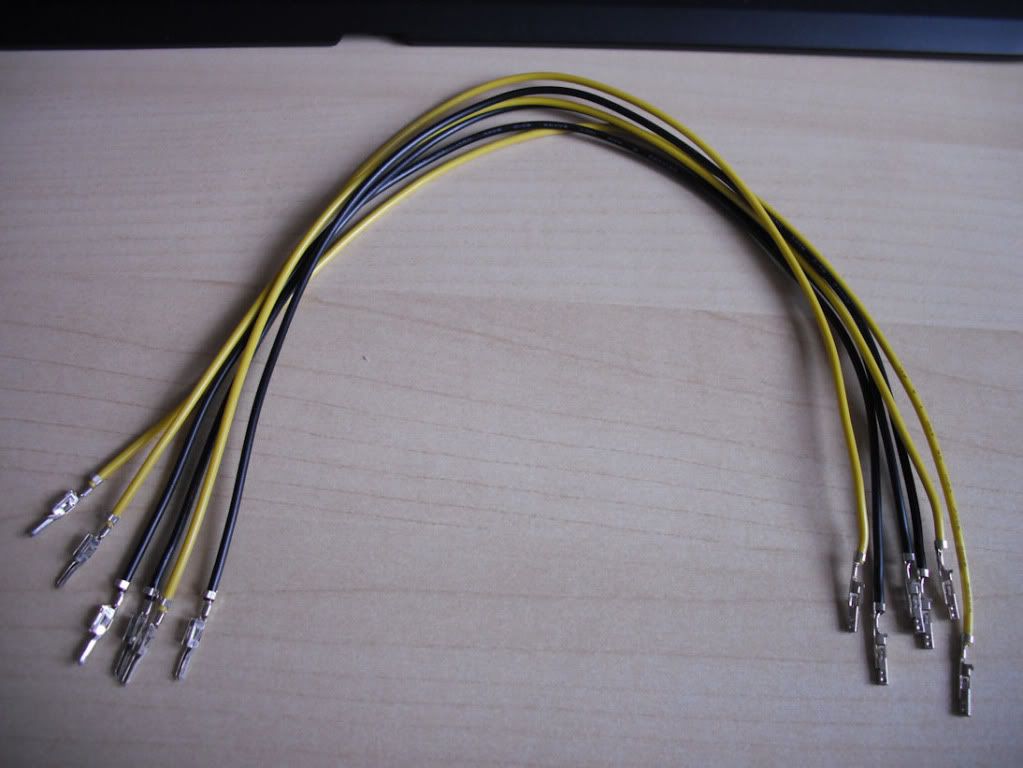

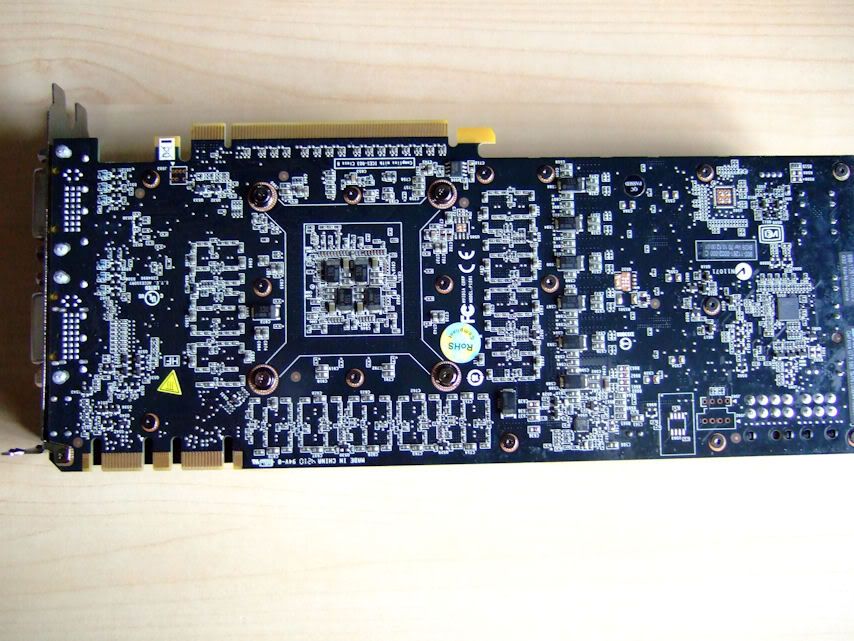

I also purchased extensions for the graphics card.

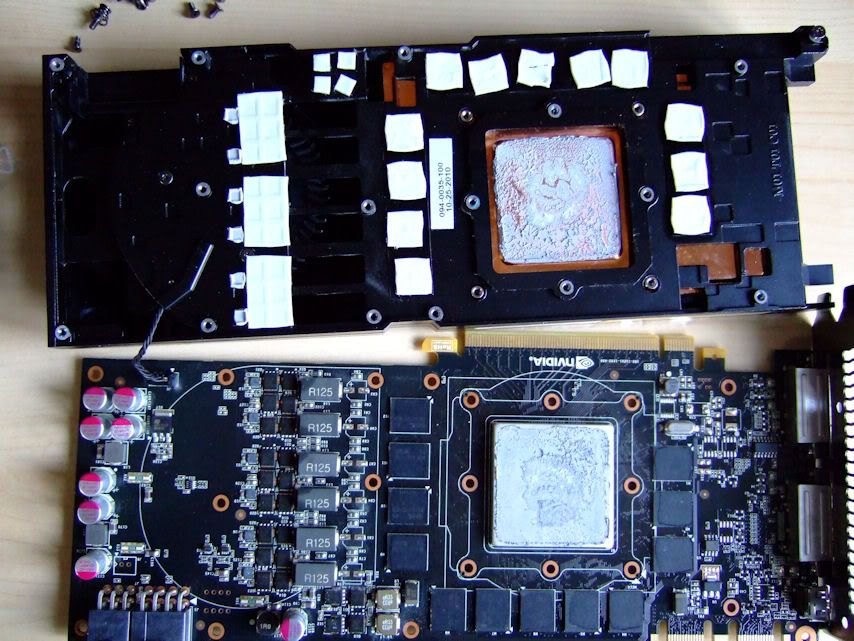

Stripped them down as before

The finished item

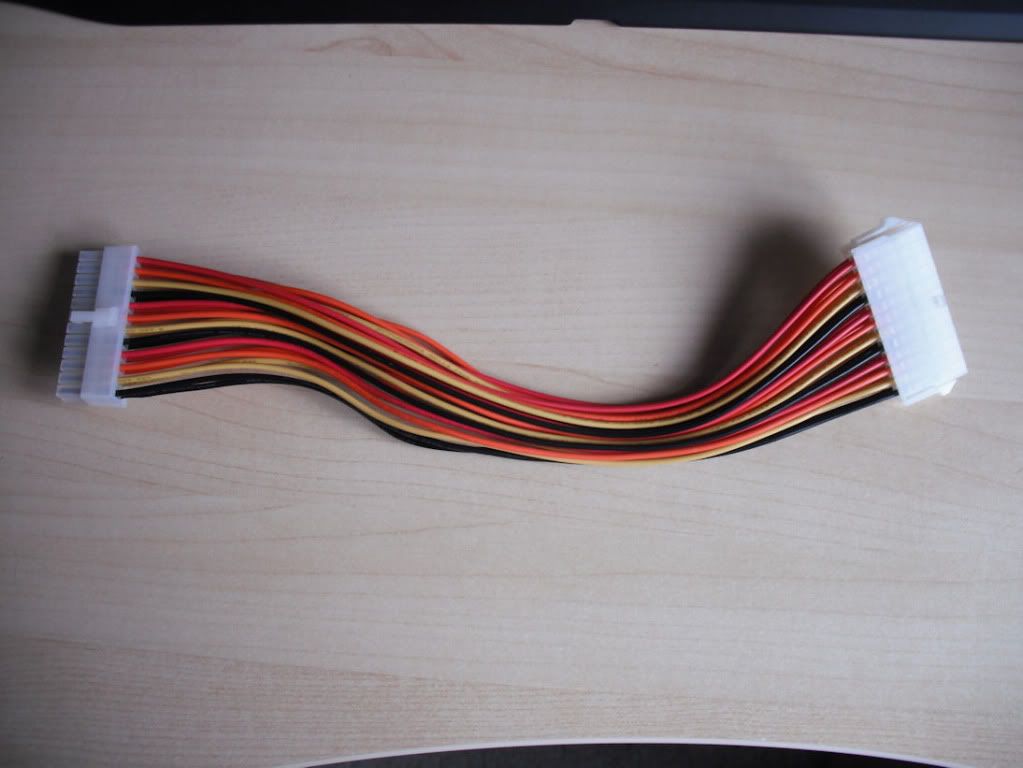

Finally the 24pin motherboard cable

The finished item

I have to say, I am very pleased with the results (even better than I thought).

Also have to say that the dense weave braid I perched from Tom is excellent and I will definitely be going back for more.

Reply With Quote

Reply With Quote

I can't believe I've missed this till now, I love it

I can't believe I've missed this till now, I love it

Bookmarks