Introduction

Here with this new round of field testing we are introducing our new thermal compound Perihelion. It’s been nearly 2 years since Innovation Cooling’s (IC) test run of IC Diamond here on XS. While XS was not the largest of any of the 12 Field tests done to date, it was certainly the most thorough of the lot. So with that in mind I selected this group to do the first public tests as it was the most challenging, results from the XS IC Diamond testing assisted us to effectively trouble shoot a number of issues like proper application amounts and mounting and hardware requirements needed to obtain best performance in addition we were able to refine our marketing message. Forum comments and feedback we received were invaluable. XS gets first look at our new compound IC Perihelion prior to product release.

So Thanks again all who agreed to participate and those who have helped us in the past.

Background

We are taking a little bit of a different track on things by adding a maximum possible performance metric for consideration rather than just a Paste #1 vs. Paste #2 sort of thing. We are fast approaching material limitations (if not already maxed out) and performance improvements from here on out will be harder to differentiate. More and more we project or expect that future buy decisions will be made on factors such as cost/quality with competitive compounds performing within a few 10th's of a degree of each other with the exception what I call the exotics like diamond and the liquid metals

To demonstrate this we soldered a sink to a test die (one inch Die @120 W) and with a thermocouple we set through a hole in the sink to measure the top of the joint to establish a maximum performance "solder line" for a practical theoretical limit to performance. In our own study there were no significant gains to be had in the thermal cascade of die, compound, sink. We are at the beginning of the end of the performance race with a pile up at the material limit wall.

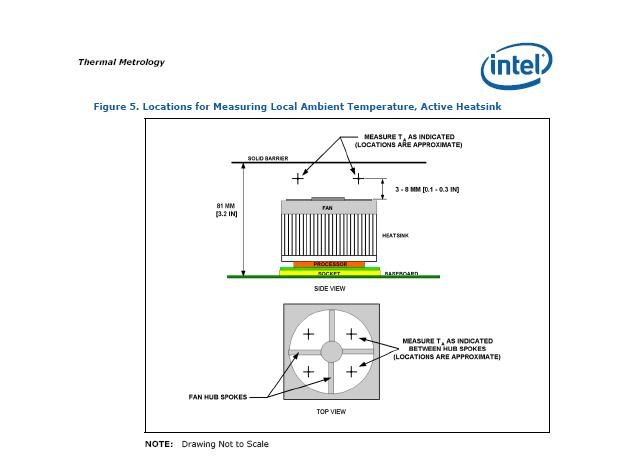

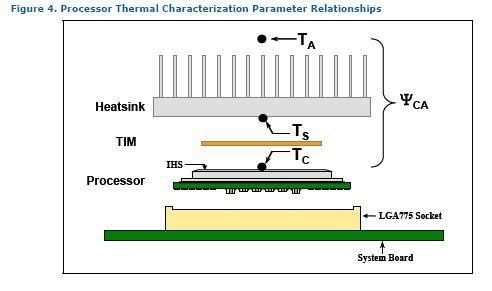

The Graphics below (Courtesy of Intel) outline how we test.

We test ambient temperature at four points an in addition we measure airflow through the sink drawing a flow/ resistance curve resistance curve and also test the fan by itself. Standard adjustments are made for temperature, barometric readings and altitude.

For thermal measurements we follow Intel's suggested method.

For the synthetic die we just replace the CPU with a 1" copper die. Synthetic test set up provides more information such as to how much power is applied to get the thermal reading and is much easier to control for mounting contact/ pressure repeatability in testing. We then use in-system-tests for a correlation to synthetic tests.

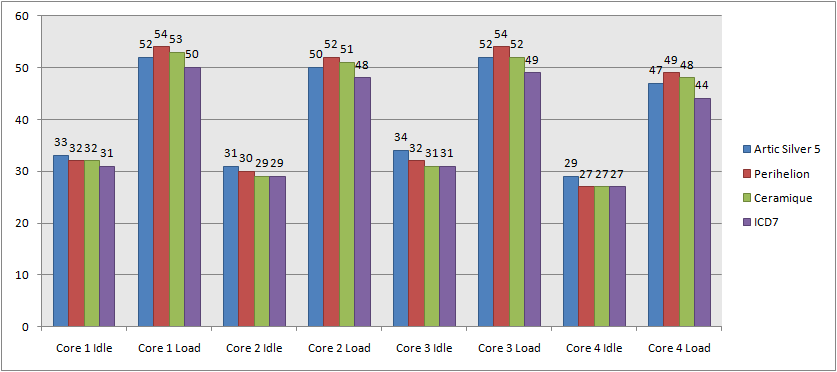

Chart below - samples are the newly released paste compounds which are pretty good performance wise. I tested all the recently released compounds in the last year the top 3 are of those shown here. So in the future it is possible we will have 10 compounds all testing inside of a degree of each other. Future product reviews of compounds will probably start with some statement that the paste has hit the standard performance mark and then move on to other features. Ultra High performance is the new average now.

Test comparison below was done on a synthetic one inch die @ 120 W

We believe this is where thermal compound becomes kind of a ho hum commodity product with cost/quality(long term reliability) becoming more dominant features in the buy decision as noted. The design target for Perihelion fills a gap in our product line for Cost/Quality/Performance in as close to an optimum balance as we could get.

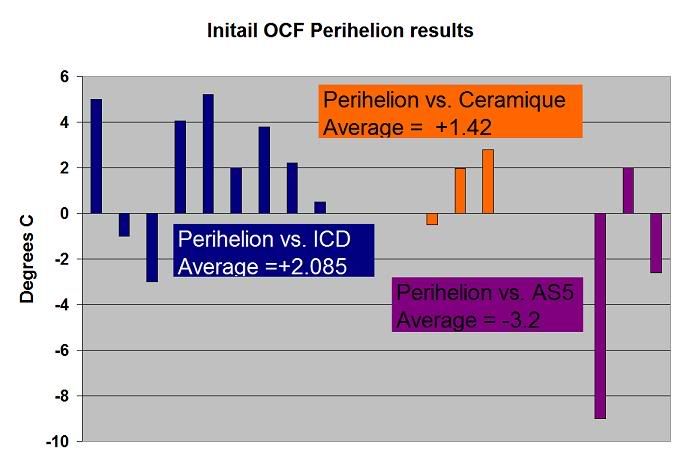

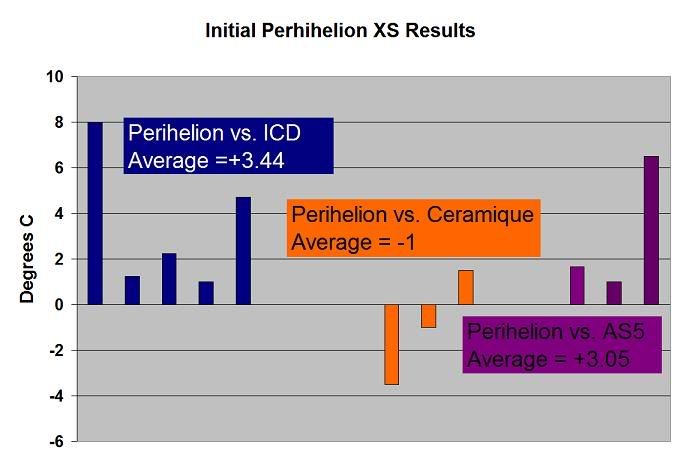

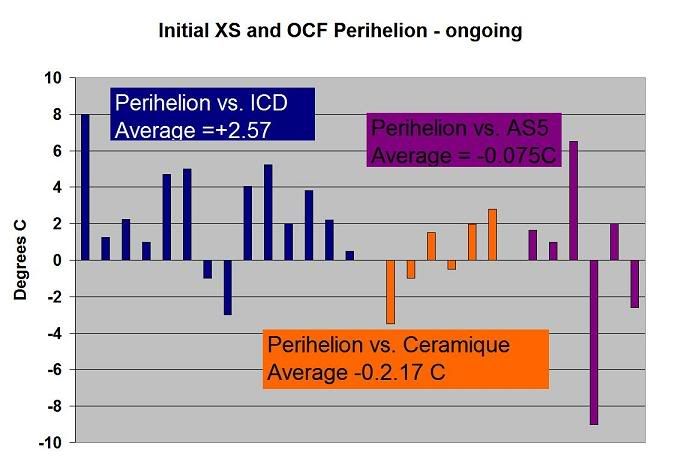

What remains is to see how our lab data translates to in-field use by actual users

Test Requirements

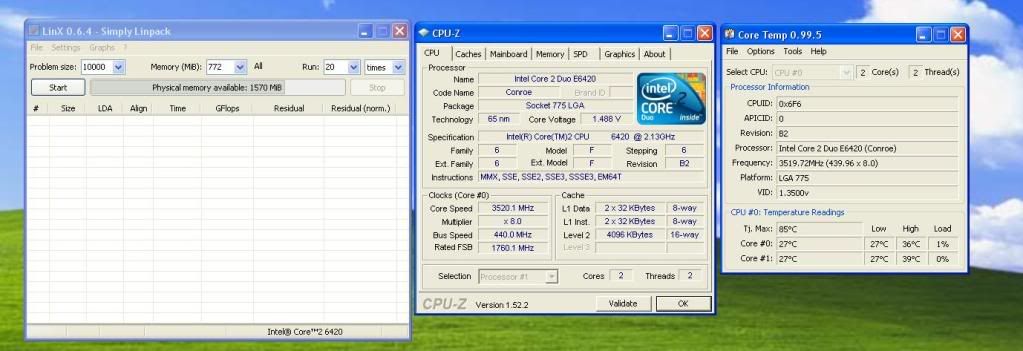

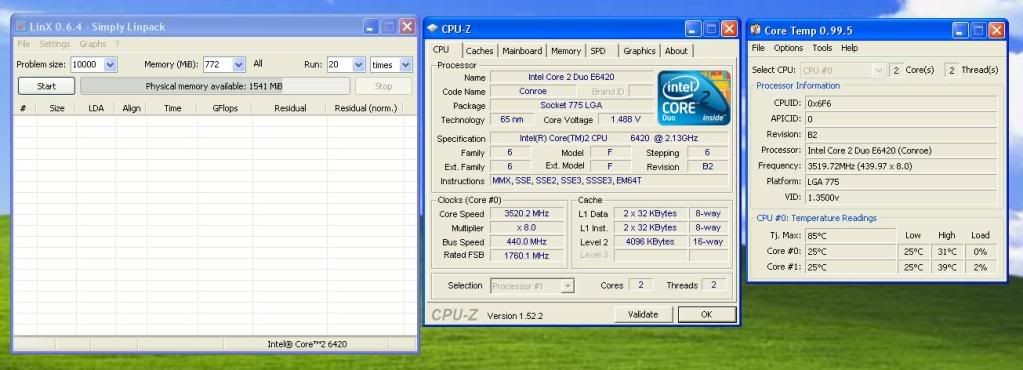

Be sure to benchmark your cpu temps with your current tim and record your results before using perihelion for testing. we need before and after please!

Also, please make sure you don't change any variable other than the thermal compound used for before/after (i.e. same volts/clocks, cooler, and other hardware)

APPLICATION METHOD

For all those participating in the Perihelion giveaway, please follow this link to the Innovation Cooling website for application instructions on the product application is the same as IC Diamond:

Perihelion Application Instructions

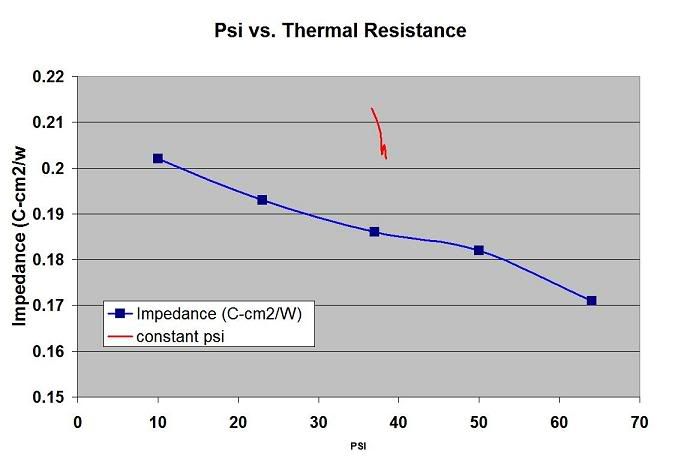

Proper application is the key to this product. The nature and consistency of this product is likely quite different from what most of you are used to in a Thermal Compound. We don't recommend use of traditional methods of applying the TIM like razor blades, lines, x's (though some people have reported great success with the X method), etc. Through extensive testing, the best overall application method has been determined to be a pea sized amount (approx. 5.5mm dia.) directly in the center of the CPU. The TIM should be adequately spread via the downforce of the CPU cooler (a sufficient amount of downforce will provide best results; minimum 50psi of downforce should be the goal for optimum results. please see the Innovation Cooling website for more info). Also, for coolers/surfaces that have many peaks and valleys, it may be beneficial to wet the surface(s) with a small amount of Perihelion to initially fill the voids in the mounting surfaces...then proceed with recommended application as usual. Please click on the link provided and shoot me a PM if you have any questions.

Keep in mind, Perihelion has been formulated with the specific goals of providing great thermal conductivity with short set times, but also for long term stability and performance without pump/bakeout through extended thermal cycling or usage. This stuff is very stable over long periods of time.

HOW TO POST RESULTS

THE FORMAT IS AS FOLLOWS (ALL TEMPS IN C):

OPTIONAL INFO: PROCESSOR, VOLTS/CLOCKS, HEATSINK/COOLING USED, ETC.

Pre-Perihelion

Compound:

Ambient Temp:

Idle Temp:

Load Temp:

Heat Sink Fan Speed:

Perihelion

Ambient Temp:

Idle Temp:

Load Temp:

Heat Sink Fan Speed:

If you have any problems or need support, please feel free to post here for now. Remember, proper application and good even heatsink pressure (goal should be minimum of 50psi or more) are crucial for peak performance. Too little compound will impact your results so please do visit the Innovation Cooling website for Application Instructions with images and explanations as well as read the review on this site as. For those with direct touch heatpipe coolers, you might want to try wetting the contact surface of the cooler with a tiny amount of Perihelion to fill any small voids before proceeding with the normal application method.

So, I'd just like to thank XS for this great opportunity and also all the participants and members. This is a great website. If anyone has any questions, please feel free to post up. Sign ups are still open and should be posted in the sign up thread.

Thanks all !

Application Notes

We strongly recommend using our application procedure out of the gate and no others.

http://www.innovationcooling.com/app...structions.htm

Correct Application AmountCauliflower like extensions indicate absorption of air. The more viscous the paste the more you have to use. With thinner or less viscous pastes the "Air Zone" is further extended .the application should look like this with a 5.5mm bead - This was tested by us and validated on a number of forums (including this one) using less will impact results negatively as shown in multiple tests.

The metric is viscosity, amount of paste to the area being covered.

Our new labels will include a 5.5mm "reference spot" to facilitate proper application.

http://www.innovationcooling.com/app...structions.htm

In this example IC Diamond was applied between two glass slides and stress tested in an oven @ 150C for 20 hours. Applied 5mm bead of ICD.

Note the halo of air bubbles, this is why it is important to apply enough compound, because as the paste thins it spreads it reaches a maximum zone where air is reformed into the paste application between the sink and IHS

In essence you need enough compound to extend the air pocket zone outside the area of IHS contact otherwise you are riding on a cushion air(an insulator) preventing full contact/performance and leading to an early failure of the mount

Note: in a rush to get up will add edits and info later

Reply With Quote

Reply With Quote

(seriously, I know it ain't happening)

(seriously, I know it ain't happening)

Bookmarks