-

Noctua NF-A12x25

Introduction

One manufacturer known for its quality, performance, and silence is Noctua. Noctua is finally launching their much-anticipated next-generation A-series fans. The NF-A12x25 is the new flagship model and took 4.5 years to develop. In comparison to the previous generation's NF-F12 and NF-S12A, the NF-A12x25 is an all-round performer providing both excellent static pressure and airflow. That means it will out perform the NF-F12 when it comes to radiator cooling, but it is also excellent as a silent case fan. I already got the full range of the latest arrivals. All of the fans are in the typical for the company pink/brown color scheme and all of them have unique features.

The NF-A12x25 is available in a 4-pin PWM version with a 1700 rpm or a 1300 rpm variant.

There is also a 3-pin FLX versions with low-noise adapters running up to 1300 rpm.

For users who want a truly silent experience, the 3-pin NF-A12x25 ULN is available as well, which ramps up to 900 rpm.

Packaging & Contents

As expected the packaging with the Noctua NF-A12x25 fans is very high quality. I've mentioned this before on previous Noctua reviews but it is worth saying again, packaging for most people falls into two categories:you think it should be as minimalist as possible to save costs and keep the product price down or you think they should put in the attention to detail to improve the overall buying experience. Noctua have clearly done the latter here.

The back side of the cover shows a brief description of the fan in nine different languages and provides the fan specifications, the Scope of Delivery again, and the Six Years of Warranty disclaimer.

Once you open up the Noctua packaging you can see what I mean about the attention to detail,although some might call it marketing overload. Either way we'll take you through all of the key features of the NF-A12x25 fans on the next page.

There is a second compartment which contains more detailed and labelled diagrams of all the key features of the NF-A12x25. Please check out the next page called "Key Features" if you are interested in these.

Once you open the box you will see the bundle contents. The next images show their accessories removed from their boxes.

The NF-A12x25 PWM includes:

-Low-Noise Adaptor (L.N.A.)

-4 Pin y-cable

-30cm extension cable

-NA-AV2 anti-vibration mounts

-Anti-vibration gasket for water cooling radiators

-Fan screws

The NF-A12x25 FLX includes:

-Low-Noise Adaptor (L.N.A.)

-Ultra-Low-Noise Adaptor (U.L.N.A.)

-3:4-pin power supply adaptor

-30cm extension cable

-NA-AV2 anti-vibration mounts

-Anti-vibration gasket for water cooling radiators

-Fan screws

The NF-A12x25 ULN includes:

-Ultra-Low-Noise Adaptor (U.L.N.A.)

-3:4-pin power supply adaptor

-30cm extension cable

-NA-AV2 anti-vibration mounts

-Anti-vibration gasket for water cooling radiators

-Fan screws

They all sit on an installation manual which is available online.

A Closer Look

Once you've observed the obvious things, like the colour scheme and nine blade impeller, you start to notice the finer details in these Noctua NF-A12x25 fans.

You're either a fan of Noctua's colour combination or you're not, and on the whole, we're not. Well, i'm not anyway. Perhaps in a white case these might look ok, but it's hard to see them fitting in aesthetically anywhere else. On the other hand, any fellow enthusiast who happens to look into your case will know that you've spared no expense in making it look ugly. And while we're at it, we don't think the exposed metal work on the hub does anything to improve matters.

Integrated anti-vibration pads made from extra-soft silicone minimise the transmission of minute vibrations while maintaining full compatibility with all standard mounting systems and fan clips used on heatsinks.

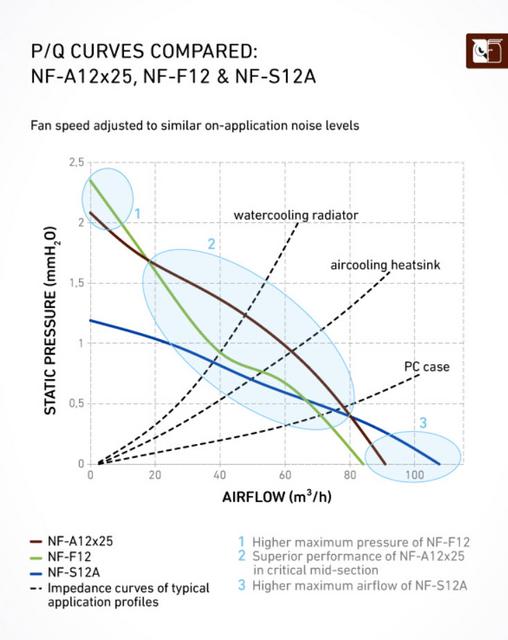

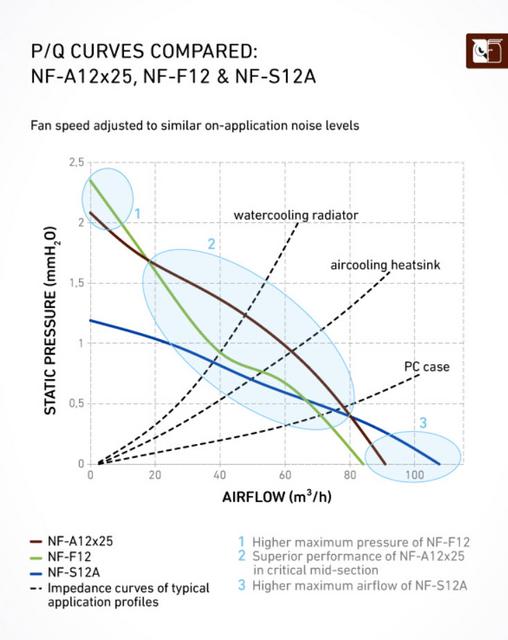

The NF-A12x25's sophisticated aerodynamic design allows for a pressure to airflow (P/Q) curve that is extremely strong in the critical mid-section. This means that the NF-A12x25 is a true jack-of-all-trades with excellent performance in both static pressure demanding and airflow demanding applications. The below chart compares the P/Q curves of the three fan models and maps them on sample impedance curves of a typical PC case, heatsink and radiator in order to demonstrate how much air the fans can push through when working against the airflow resistance that these applications represent. As can be seen from the chart, the NF-F12 produces higher maximum static pressure (top left) and the NF-S12A produces higher maximum airflow (bottom right), but at the relevant operating points, namely the impedance curves of the three sample applications, the NF-A12x25 provides a better balance of static pressure and airflow than the other two fans. This is the cornerstone of the NF-A12x25's superior real-world performance.

One of the crucial design measures that allows the NF-A12x25 to further improve its renowned predecessors performance is its record tight tip clearance (distance between the blade tips and the inside of the frame): whereas most 120mm fans have a clearance of at least 1.5 to 3mm, the NF-A12x25's ultra-small gap of only 0.5mm sets a new benchmark. This highly ambitious design enables the fan to work more efficiently against back pressure, such as on heatsinks or radiators, because it reduces leak flows through the gap between impeller and frame. However, it also poses novel challenges in manufacturing. Producing a fan with a tip clearance of only 0.5mm not only requires much higher precision and stricter tolerances in general, but also makes it necessary to tackle creep phenomena that are irrelevant for fans with a bigger tip clearance. Over extended periods of use and thermal cycling, axial fan impellers undergo minute creep deformations due to the centrifugal forces pulling the mass outwards, which result in minute increases of the fan?s diameter.

For example, the impeller of a typical 120mm fan made from standard PBT can become larger by as much as 0.2mm over several years of usage. With fans that have a larger tip clearance, e.g. 2mm, this is not a problem, but with a tip clearance as small as 0.5mm, impeller creep becomes a major issue and even a 0.2mm creep will result in a high risk of the blades making contact with the frame if there is any minute vibration or imbalance. In order for these challenges to be met, Noctua has taken several different measures that, from a manufacturing point of view, make the NF-A12x25 the most advanced and most elaborate Noctua fan to date. Firstly, the centrepiece of the NF-A12x25's motor hub is made entirely from steel in order to reinforce the outer plastic structure. At the same time, the axle mount has been reinforced with an additional brass piece in order to stiffen the joint between axis and impeller. In combination, both measures assure reduced tolerances and increased stability in the critical hub area.

The key to overcoming the impeller creep issues, however, was the development of Sterrox, a novel liquid-crystal polymer (LCP) type material that has much better dimensional stability and less creep as compared to conventional engineering thermoplastics such as ABS, PA, PBT or PC. The name Sterrox is derived from the Greek word στερρός, which means stiff, firm, solid, hard or rugged. Liquid crystal polymers possess remarkable chemical and mechanical properties, such as high tensile strength and environmental inertia, that make them ideal for high-end medical and military applications with demanding requirements and budgets that can support the high material cost (roughly four times as high as PBT). The most well-known LCP is Kevlar, which is being used in products such as bulletproof vests, combat helmets and other body armour due to its excellent strength-to-weight ratio. The remarkable mechanical rigidity of LCP materials is due to their unique molecular structure: unlike conventional polymers, which have a chaotic molecular chain orientation both in solid form and in the melt phase, thermotrophic LCPs such as Sterrox show an ordered, rod-like molecular alignment even in the melt phase and solidify into a highly oriented, extremely rigid chain structure, which gives them much more advanced mechanical properties.

Sterrox is Noctua's own customised type of fibre-glass reinforced LCP that has been specifically fine-tuned for use in next-generation fan designs such as the NF-A12x25. Its extreme tensile strength, exceptionally low thermal expansion coefficient, high environmental inertia and excellent dimensional stability have made it possible to reduce impeller creep phenomena to levels that were previously unthinkable with PBT- or PA-based impellers.

In addition to permitting fan designs with much lower tip clearances, Sterrox provides a second key advantage in having an elasticity modulus and damping properties that are ideal for reducing resonance and vibration phenomena in advanced fan blade designs such as the NF-A12x25. In particular, the use of Sterrox allows the suppression of a phenomenon called blade surface mode vibration: a fan impeller has a natural frequency and multiple resonant modes. When the fan is running, the turbulent air around the fan blades will transfer vibration energy into the blades and cause resonant vibrations.

These surface vibrations are so minute that they are not critical from a mechanical point of view (unlike e.g. vibrations due to imbalance), but they can cause serious acoustic problems. The reason for this is that when the fan is running, there is a pressure difference between the intake and the outlet side of the fan (lower pressure on the upside of the blades, higher pressure on the downside of the blades). From an aero-acoustic point of view, this situation is similar to a stereo speaker where there is higher pressure inside the chassis and lower pressure outside the chassis. In both cases, the pressure difference leads to an efficient acoustic coupling, so the surface vibration of either the blades of the fan or the membrane of the speaker is transferred to the air. While this acoustic effect is desirable in the case of the speaker, avoiding it is crucial for fine-tuning the sound signature of advanced fan blade designs and this is where the increased stiffness and improved damping properties of the Sterrox LCP material come in: when comparing the same fan blade design made from PBT and Sterrox and measuring their surface vibrations with a contactless Doppler laser vibrometer, the Sterrox impeller damps the same vibration excitement much quicker.

In real-world usage, this means that less vibration from air turbulence is transferred to the fan blades and, consequently, fewer surface mode vibrations are transferred back to the air as noise, which significantly contributes to the NF-A12x25's smooth acoustic profile.

Next to aerodynamic noise and bearing related noises, the so called "commutation noise" or "switching noise" can play a major role in the noise emission of axial fans with brushless DC motors. At each transition from one stator coil to another, the rotor receives a sudden torque pulse when the next coil switches on. Each of these torque pulses causes a minute deformation of the whole fan structure. Depending on rpm, torque and the material of the fan, this can result in noticeable noises. Noctua's Smooth Commutation Drive system provides more continuous switching in order to achieve a smoother transition between the stator coils and thereby significantly contributes to the fan's overall quietness. The second generation of this technology (SCD2) further improves running smoothness and reduces minute noises in close proximity to the motor.

Inner surface microstructures are an advanced aerodynamic design measure first introduced with Noctua's NF-A12x25 fan. Miniature dents at the inside of the fan frame create a turbulent boundary layer when the fan blades pass by. With the tips of the fan blades ploughing through this boundary layer, flow separation from the suction side of the blades is significantly reduced. As suction side flow separation is a major source of axial fan blade passing noise and leads to considerable losses in airflow and pressure efficiency, the use of Inner Surface Microstructures allows for lower noise emission and better performance at the same time. Reducing undesired turbulences caused by suction side flow separation, Inner Surface Microstructures help Noctua's latest fans to keep pushing the boundaries in performance to noise efficiency. The NF-A12x25 impeller features suction side Flow Acceleration Channels. By speeding up the airflow at the crucial outer blade regions, this measure reduces suction side flow separation and thus leads to better efficiency and lower vortex noise.

Custom designed PWM IC with SCD Noctua's custom-designed NE-FD1 is a next-generation PWM fan driver IC that integrates Smooth Commutation Drive (SCD) technology for quieter operation and allows for ultra-low power consumption. Its superb linearity and security features such as locked rotor or reverse voltage protection make it an ideal driver IC for premium-class PWM fans.Most conventional PWM fan driver ICs put out square signals that cause sudden torque impulses. These impulses can cause minute deformations of the entire fan structure which lead to audible "clicking" noises that are especially noticeable with many common PWM fans running at slower speeds. Adopting Noctua's Smooth Commutation Drive (SCD) technology, the custom designed NE-FD1 PWM IC slows down the slew rate of the output signal in order to give a smoother, less sudden torque impulse. This way, PWM switching noises can be effectively suppressed and the fan runs even quieter, especially at low speeds.

The NF-A12x25 features the further optimised second generation of Noctua's renowned, time-tested SSO bearing. With SSO2, the rear magnet is placed closer to the axis to provide even better stabilization, precision and durability.

Test System & Methology

Testing a high-end fan such as the Noctua NF-A12x15 is tricky and somewhat inaccurate given the tolerances of both a silent cooling device and the harsh environment found inside every computer case. For now, Noctua is only releasing the 120mm NF-A12x25. However, for users who want to use it on a 140mm mount, there is the NA-SFMA1 accessory. This is basically just a simple adapter which allows users to mount the NF-A12x25 into a 140mm mounting space. And that kit i used in our scenario adding two Noctua NF-A12x25 PWM fans on the NZXT Kraken X62 AIO. Ambient temperatures are kept at 23C throughout my tests. Idle temperatures are obtained after booting the PC and idling on the desktop for 30 minutes. Load temperatures are obtained after running OCCT test for 15 minutes. To measure noise levels i disable the two front in-take fans, rear exhaust and GPU fan.

Testing Setup:

Processor: AMD FX-6350 @ 4.5 GHz

CPU Cooling: NZXT Kraken X62

Motherboard: ASUS 970 Pro Gaming/Aura

Case: NZXT S340 Elite

Memory: CORSAIR Vengeance 4?4 GB @ 1600 MHz

Video Card: XFX HD 7970

PSU: Antec TruePower New TP-750

Hard Drive: Corsair Force GT 240 GB

Optical Drive: N/A

OS: Windows 7 Pro 64-Bit SP1

Performance

As you can see the results the Noctua NF-A12x25 comes out with slightly lower temperatures.

The Acoustic performance of the Noctua NF-A12x25 speaks for itself, that's if you can even hear it! You can see all that slaving away by Noctua to fine tune every part of their Noctua NF-A12x25 fan has paid off.

Conclusion

Testing out these new fans from Noctua makes me realize just how much I like the innovative designs of their products. They do not simple take the ideas from others and make small improvements.They throw the book away and start from scratch. The Noctua Noctua NF-A12x25 may only be a fan, but I have never seen a fan where so much attention to detail has been made to every aspect of its design, airflow, noise, power consumption, aesthetics, accessories, durability and quality. With their static pressure are ideal fans for any CPU heatsink, radiator, chassis or all in one loop. In terms of noise our results spoke for themselves, they were absolutely outstanding and this is where the Noctua NF-A12x25 really shines the most.

Considering most 120mm fans cost around $7-10 the Noctua NF-A12x25's are far from cheap (EUR 29.90 / USD 29.90), in fact they are nearly thrice the price of a standard 120mm fan, but at the end of the day Noctua aren't trying to churn out of thousands of cheap and cheerful fans for the mass market. They have developed something niche and specialised. The quality of the NF-A12x25 fans is as usual up to the high quality what we've come to expect from Noctua over the years. Noctua guarantees these fans for 6 years (more than 150,000 hours) so they are a good choice especially if you are going to leave them running for days, weeks, or even months on end. If you're comfortable with the colour scheme and happy paying the premium-level pricing, then you'll be more than happy with the excellent performance that Noctua's latest offerings bring to the cooling fan market.

Last edited by testman78; 07-23-2018 at 09:50 AM.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Reply With Quote

Reply With Quote

Bookmarks