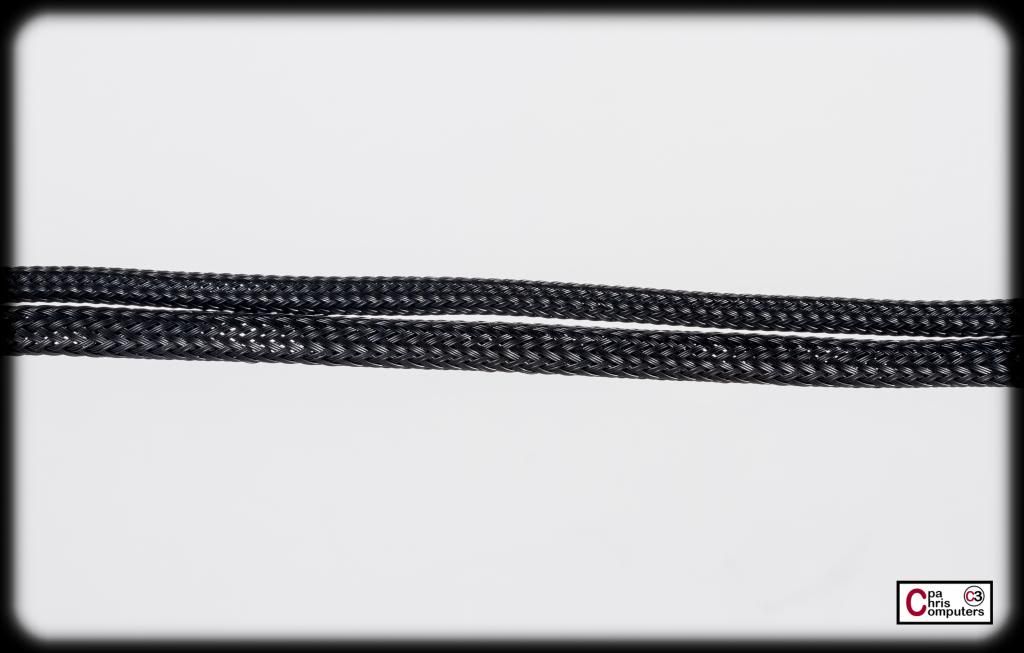

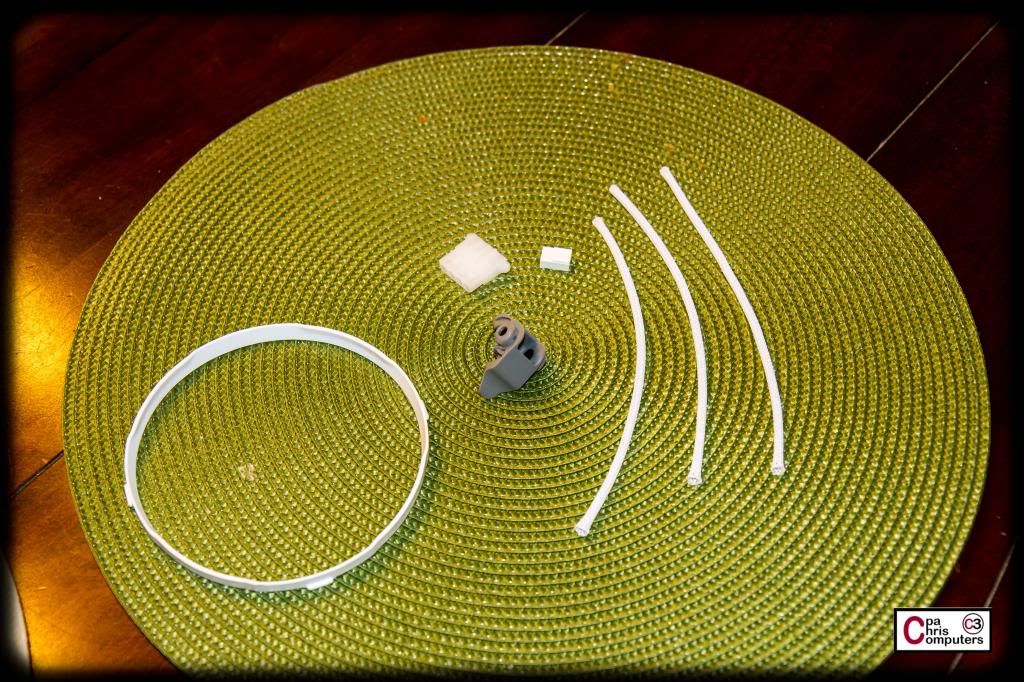

Here are some comparison shots between Telios and MDPC-X.

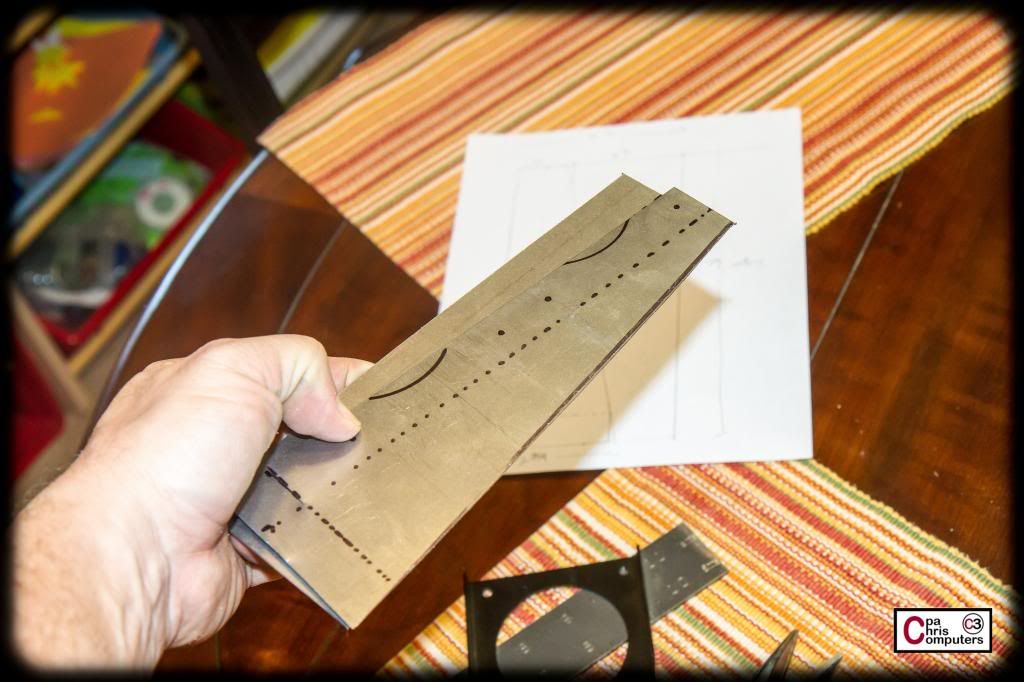

For all of these shots, the Telios is on top, and the MDPC-X is on bottom. First the black sleeve.....

It's pretty easy to see that the Telios is a smaller diameter sleeve. In theory, you would think that this would make it grab the wire better and be easier to stretch tight. I'll let you know if that's true once I start sleeving with it.

Closer up....

The shades of black color are almost idenitical. No real difference there at all. But there is no doubt that the Telios is a tighter weave. Take a look in the picture above at how many specs of light you can see through the Telios sleeve vs the MDPC-X sleeve.

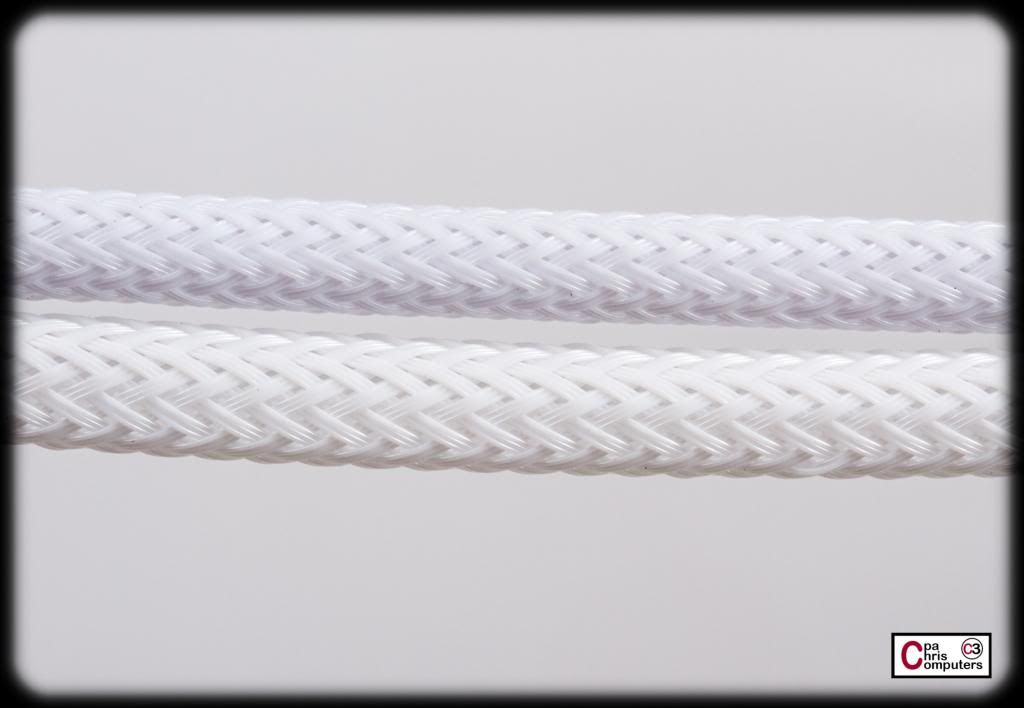

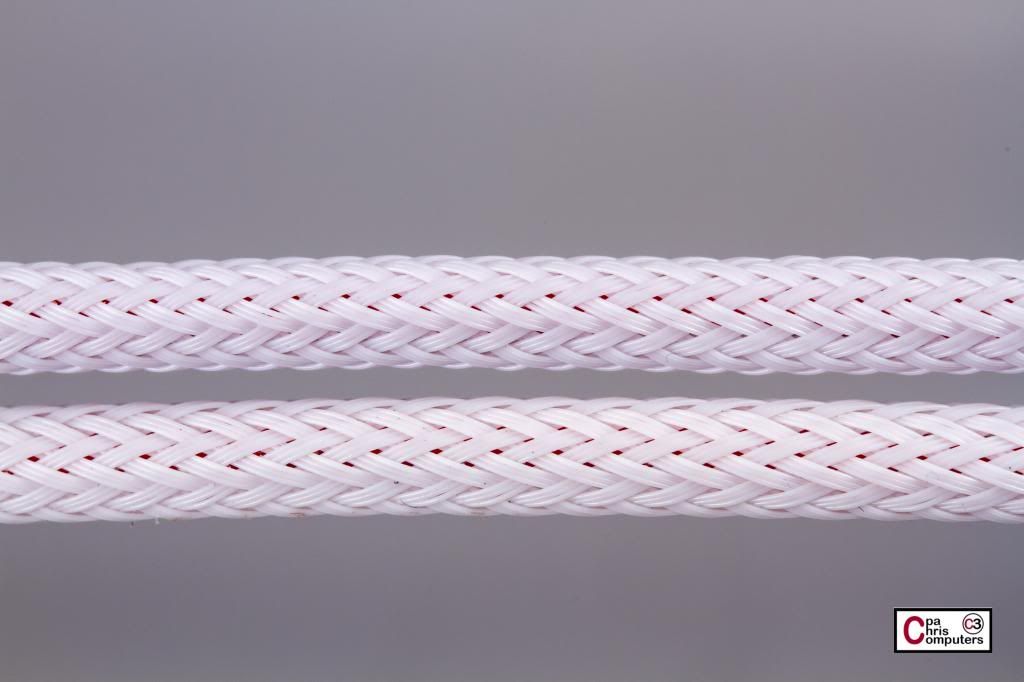

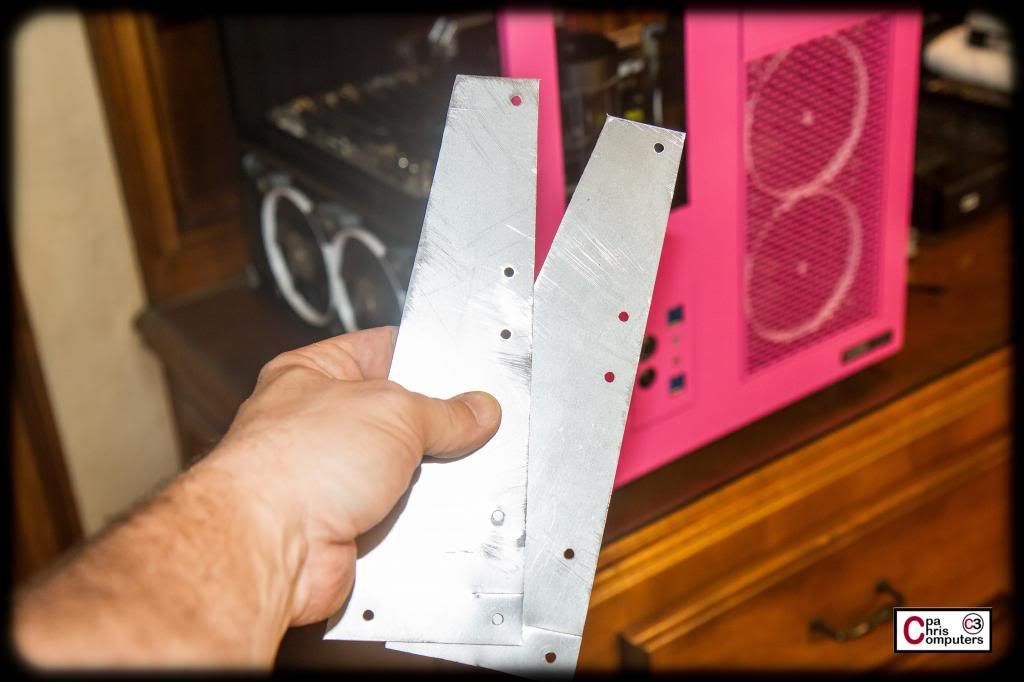

Below is a shot of the white sleeve. Again, Telios on the top, MDPC-X on the bottom....

The shades of white are very different bewteen the two, with Telios being cooler white vs MDPC-X being a warmer white. Easy to see the size difference still....

...and when you get closer it's easy to see that the weave is tighter for Telios.

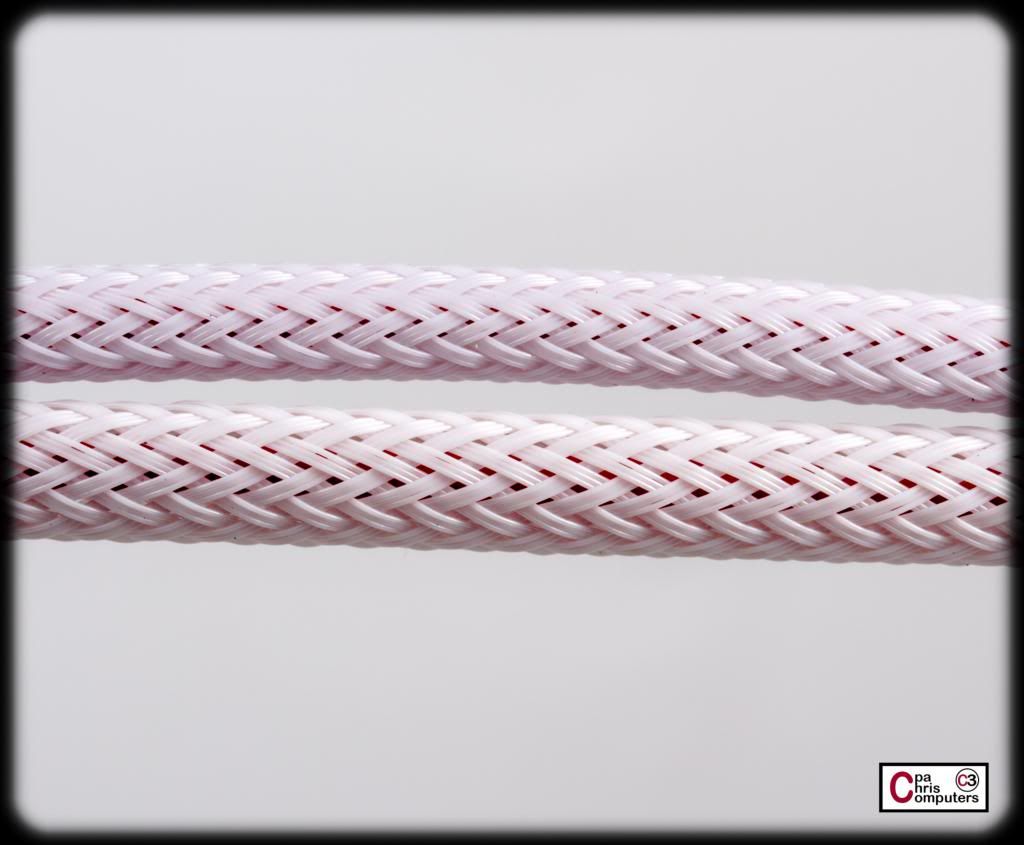

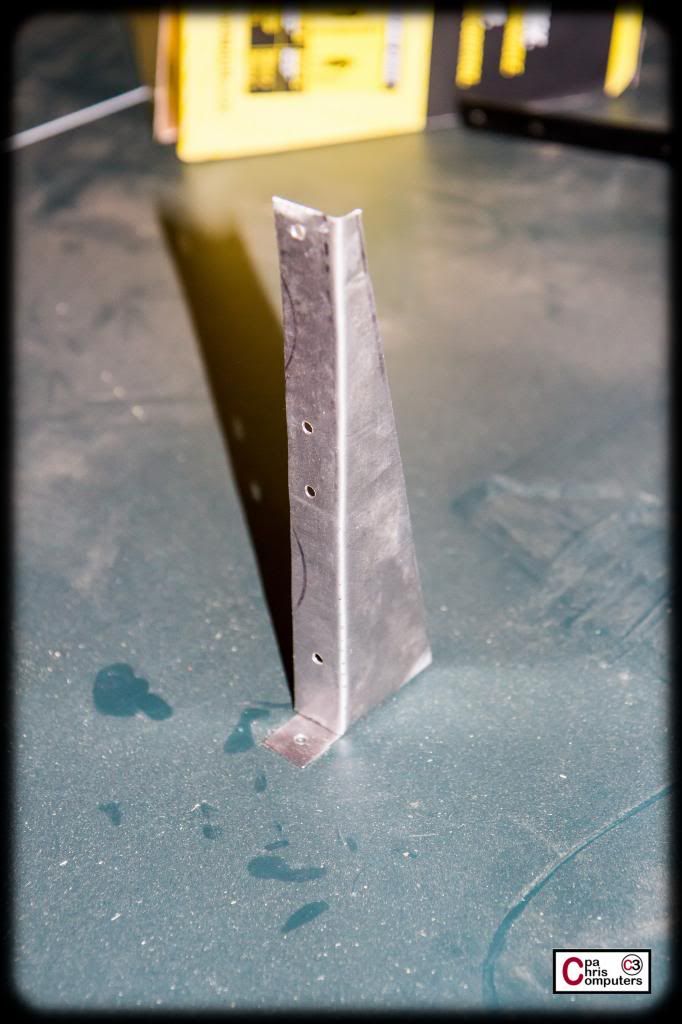

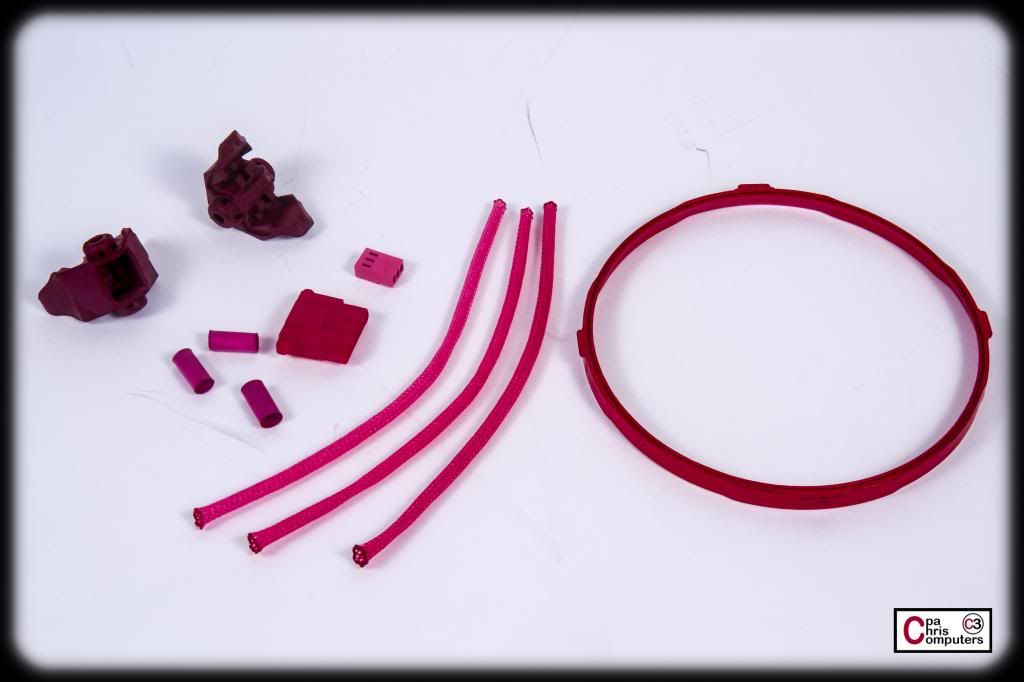

Now...I would never recommend sleeving red wire with white sleeving without taping up the red to cover it first. But....just to see if the Telios covers better than MDPC-X....lets do it. I put a piece of red 18 awg wire in each of the pieces of sleeve. Still not stretched, so this is just about as bad as it could ever get with regards to coverage.

While neither sleeve can hide the red wire without stretching it tight....it is easy to see that the MDPC-X shows more of the red specs of wire beneath the sleeve than the Telios does. So I think it's fair to say that you are going to get better coverage from the Telios.

They almost look pink! Maybe I don't need to dye the sleeve after all...... :p

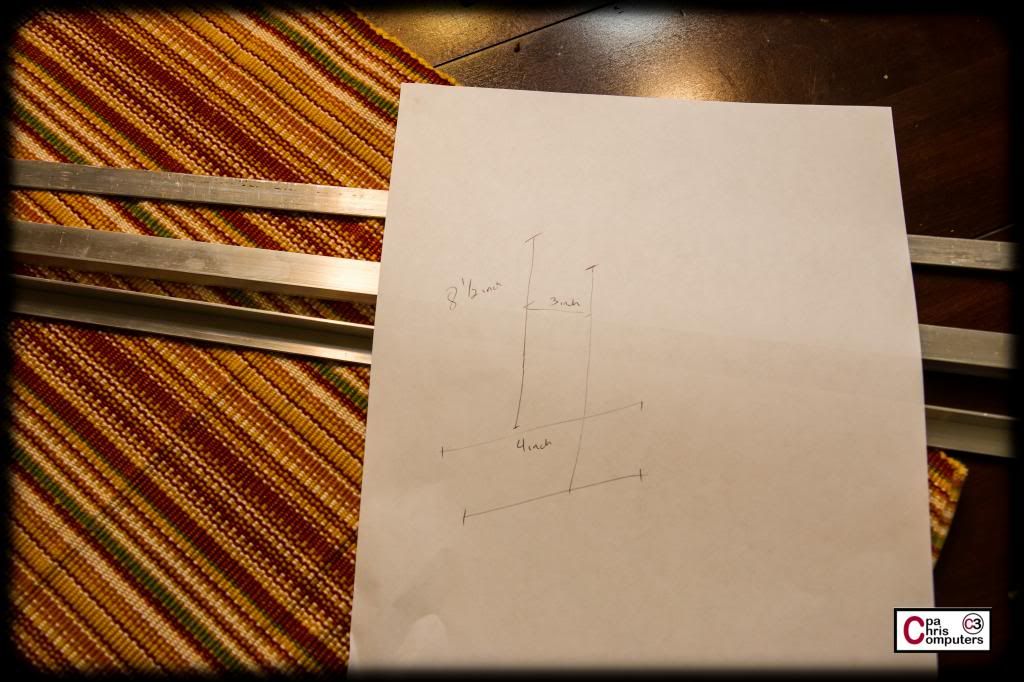

What is the difference in cost? Well....that takes a little math. Any CPA's in the house? Oh...wait. Ok...I'll give it a shot. Nil's sells MDPC-X by the meter instead of the foot, and you pay by Euros, not $'s. So we need to do a little conversion. And while we are at it, let's go ahead and set up a scenario where you are getting 200 feet of sleeve. That's enough to do a sleeving job for most computers. Not all. But it gives us a start at estimating total cost for a sleeving job between the two (without the heatshrink, terminals, etc....just the sleeve):

Telios -- As of today, the cost is $6.75 for 25 feet of black. You would need 8 packs to get 200 feet. 8 * $6.75 = $54 bucks. Shipping for the 200 feet of sleeve would cost you another $6 bucks, for a total cost of $60.

MDPC-X -- As of today, the cost is six euros for 10 meters of black....or about 33 feet. So you would need 6 packs to get about 200 feet. 6 * six euros = 36 euros. As of today, the conversion rate is 1.38, so it would cost you about $50 bucks. So the sleeve is a little bit cheaper than Telios was. Not much....but every dollar counts, right? However, the shipping on this one will cost you another 9.70 euros, which is about another $13. Total cost of $63.

So the cost is pretty similar between the two, and the $3 difference is not even something to consider when you are working on your $5k gaming rig, right? For quite awhile, Nils would only open up the MDPC-X international shop for a few hours at a time, and only a couple of times a week. So....ordering it was a process involving finding out when the next opening would be, setting your alarm for whatever ungodly hour it might have been in Germany, and then quickly filling your order online before the store site went down again. Although this difficult ordering process did create a certain mystique about the product, I always found it to be quite annoying. Not sure if it's been changed permanently or not....but for awhile now the MDPC-X online store has been open every time I've visited. So maybe that policy has changed. It will take you a little bit longer to have MDPC-X shipped to you though. If you are getting Telios through FrozenCPU, ...you know how fast they ship and you have options on the shipping method.

Hope that helps if you are trying to decide between the two. I'll pass on more thoughts as I start using it, but Telios appears to be a very attractive option for sleeving.

Reply With Quote

Reply With Quote

Bookmarks