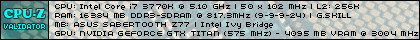

"Long time lurker" is a bit of an understatement for me, but I have been working on another cooling setup recently and since TEC's get no love, as witnessed by the ZERO threads in this forum, I decided to post this here. Keep in mind I have already been running a TEC direct die block setup for almost a year now 24/7.

So I was tossing up the idea of building a small TEC chiller to run in front of my SDD Arqtik block for a while, but it was just an idea I was tossing around on my backburner.

Fast forward to last week, I was looking through some forum classifieds for an AIO cooler for a rig I am building for a friend. Low and behold, I stumbled on someone selling not one, but two of the Mindchill Arqtik chillers and the dual controller. I only really needed one, but they are hard to find and the price was decent so I jumped on it... Just the 2 chillers kept a 3770k at 5ghz in the 50s, so adding them before my single TEC block should be interesting. Current plan is to set chillers to keep coolant temp at dew point (~10c), then run the SDD block at full tilt. Should be interesting what the block will do with now with ~30c cooler water on the hot side. I would love to see low 40s load @ 4.8ghz like that .

New cooling setup will be:

Cold side: MCP655, 2x Arqtik chillers in series on dedicated bit-chill controller, Arqtik Single Direct Die on a second controller, all 1/2" barbs, pump and all 3 TECs at 14v.

Hot side: MCP655, Three Black Ice GTX 480 Quad radiators in series, Dangerden dual bay res, a million 80CFM 120mm server fans

GPUs: MCP655 modded for G1/4" barbs, modded CPU coolers on both GPUs, Aquacomputer AMS 280mm Rad, modded stock VRM plates w/ fans, Phobya tube res

...everything will be internal - 3 separate loops, 3 pumps, two chillers, one TEC block, both controllers, three 480mm rads, one 280mm rad, both reservoirs, approximately 30 120mm 80cfm Globe server fans...WHEW.

This is the data sheet for the TECs http://www.customthe...CZ_spec_sht.pdf. I will be running 3 in series, one in each chiller and then one directly on the CPU, all at 14vs.

Reply With Quote

Reply With Quote

Bookmarks