Here I will post my worklog of attemting to extract every drop of heat sucking performance out of the 4770K's Heat spreader. After delidding the processor, it was quite apparent that the thermal compound Intel uses sux, and my heatspreader did not sit perfectly atop my core. After my naked Haswell experiment convinced me that running the processor in the nude as if it were some sort of AMD Barton 2500+ was not the ideal solution, I decided to "re-lid" my haswell. If the processor still sux after this, ill buy a new one. If anything, this will be a good experiment for when I do get a fantastic haswell.

Anyways, after delidding the processor I noticed my vice put little teeth marks on the heat spreader. Step 1 was buff those down

Now, I measured the width of the CPU core and where it sat on the die. I didn't want some crappy machining, and unwanted plating to come between my cpus core, and the heat extracting copper of the heat spreader. This was all done by carefully buffing away at the die landing area until all deep machine marks were gone and the plating was removed from the location. I did not do any unnecessary buffing here, only what was needed to get the job done

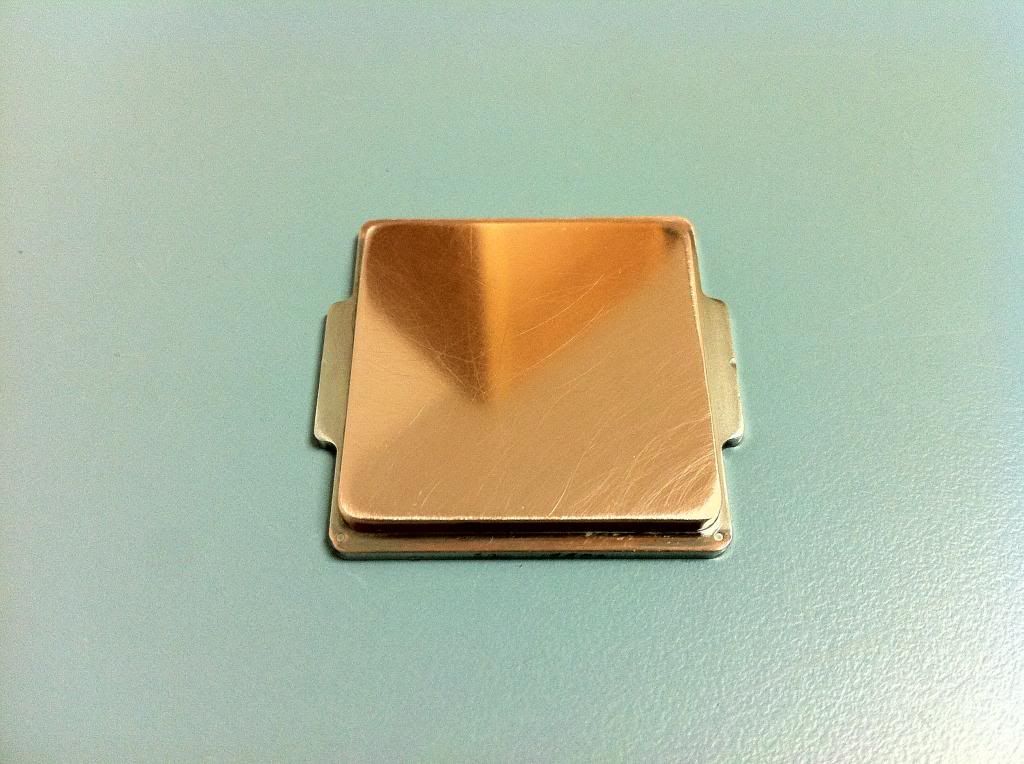

I then micro polished the area with some compound we use at work on certain aircraft parts. Guess what took this picture... lol

Now I move onto the heat spreaders top surface where it makes contact with the cooler. I started with 1200 grit wet sandpaper and went to work. I immediately realized the heatspreader is not flat. This is even after I worked on it for quite some time. I should have taken a picture to show just how concave it was.

Here it is all nice and flat from sanding with the 1200

I then began working on it with 2000 grit

After that was done and I removed most deep scratches, I use 3000 grit to smooth it all out

Here it is awaiting its final buffing before being reapplied to the processor.

Next step, Tune the mounting surface of the heat spreader so that the core landing area makes level and even contact with the Core of the processor. I want there to be just enough room for a bit of coollabratory liquid ultra to fill any imperfections in the two surfaces but I want the core as close to the copper as possible.

Stay tuned

Reply With Quote

Reply With Quote

Bookmarks