Hello guys,

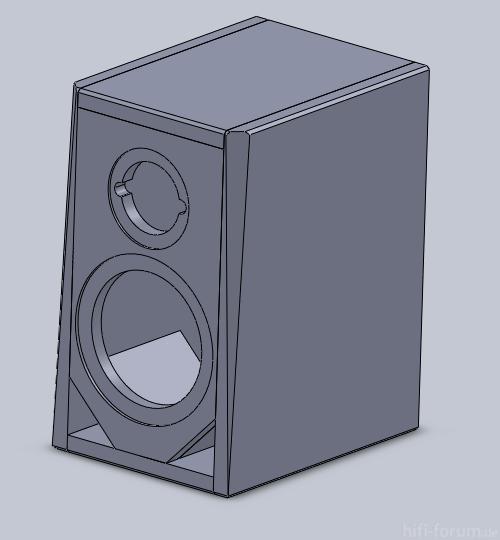

i have build two frontspeakers to test my new Cnc Machine. I looked for a small 2way frontspeaker with a 6,5" driver. There i found the Quickly 18 by Udo Wolgemuth. The kit will be cost 144€, And this speaker are a realy good investment. The speaker have a volume of 18liters. Not to small but not to large for a small room about 18qm. As bass, he select a Gradient Select W176-4. SPL is good about 89DB. MMS is convincingly with 15,8gr and the Fs sounds promising about 40hz.

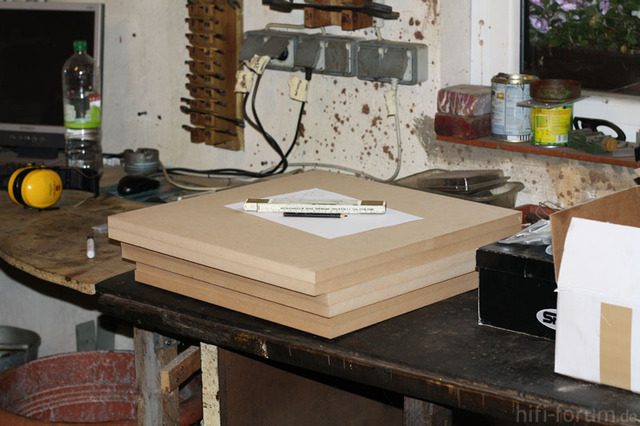

As tweeter he select the 1" Gradient Select GDT 104 N. The tweeter generated 92db and he must cut up to 1500hz. For a first build a try it with 19mm MDF.

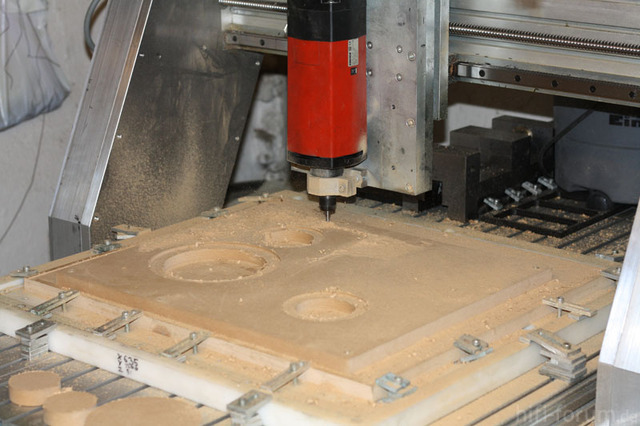

Ok, just stress testing the cnc machine.

Ok, the parts are done. Now i must glue the parts to form a box. Its also important as the accuraty of the blanks. Admittedly, the blanks are more accurate as the stick because i tried this in first time. Buts its ok. Then it will be hard to sand all surfaces well. I am happy the cnc machine works accurate. But i have fear to break a milling cutter. There i work to slow and the garage was extremly dusty. It was hard to get it clean together. I have collect aprox. 30L dust in a big garbage bag. My diy extraction does not work -.-

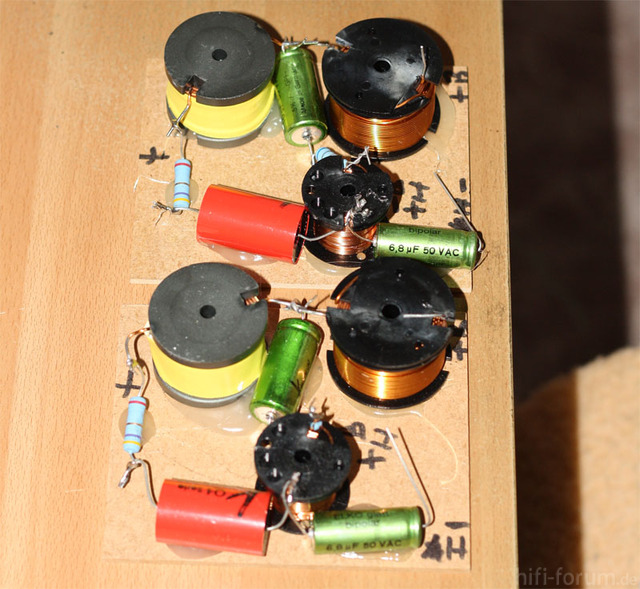

Ok, now we have a Box. Time to present the speaker and the frequence flank.

Also we have a finish box. Now i must put the frequence flank and the driver in to the Box and connect the cable to the terminals. Ok, all done. Time to hearing. I'am suprised. The small box goes big. At first, i have checked, is the subwoofer on? Ok, the sub was off. Amazing what generate a deep frequenze the tiny speaker. The Tweeter works good. Not to softly and not to hard but very clearly for this price. All tests are succefully and i had never heared more hifi for 144?. Before, i had Wharfedale Diamond 8.2. (250€) They have a 6,5" driver too. But this speaker get out about 55hz. The Quickly 18 works good up to 45hz. Deeper the speaker plays diffident. 45hz is ok for the natural music. Electronic, you take a subwoofer to support the speaker.

It was a nice project to test the cnc machine. Coming next, i will build a tiny active Speaker with a 4" woofer. The woofer have a xmax up to 9.5mm and the volume is 4L. Its a combination with a Aurasound NT1-204-8FB and a Aurasound NS3-193-8AB. The Box was called CT227 MKII. But in this project, i will veneer the surfaces. Its a next step to build a 5.1 System. I will build the Vota 1 Vota 2 and vota 3 by Udo Wolgemuth. I hope these are my masterpieces.

Best regards Marc

€dit:

Specs about the cnc machine:

XYZ: 630x1180x130mm

weight: i think 600-700Kg

Vmax: 17m/min in X and Yaxis| Z axis 6m/min

Accuraty: about 0.05mm

16mm ballscrew spindles

digital amplifier up to 5,6A - 80V

4A Stepper

Linerguidings on Y axis 25mm, X and Z axis 20mm

Reply With Quote

Reply With Quote

Bookmarks