Been working on the case a bit today. Mostly filing. I removed one of the sides of the 5.25" bay things. It will be reinstalled but cut down to only hold the front 5.25" covers in place. I hope to have the radiator supported by the one side only. That way you'll be able to see the radiator, reservoir, and pump entirely w/o them being hidden. Next up is cutting the new motherboard tray.

Here are a few pics w/ better lighting of how the case was yesterday.

My modding koozie.

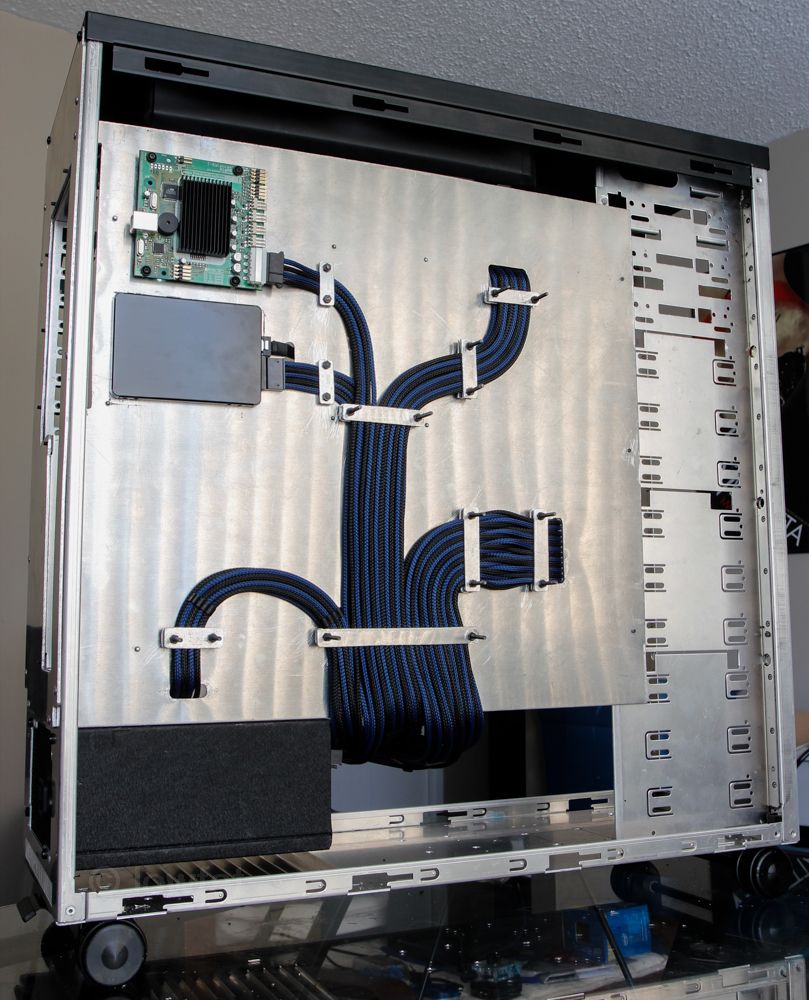

Working on the cable management floor plan. I don't want to be drilling a million holes this time around. Planning out every single cable before I do any cutting.

I attempted to counter sink the rivet holes on the back of the case. Carefully used a 1/4" drill bit to sink them. The grade on them isn't perfect but I wasn't able to find counter-sinking tools that were designed to under 1mm drill depth.

Also finished cutting out the center of the backplate. Have a few small mistakes but I am happy w/ the outcome. Especially for a first time and doing it by hand. If only I had a CNC.

Got some new nibblers today. Bessey again. They work so much better than my older ones. Except they mouth on them doesn't open as wide so they cannot be used w/ anything larger than 1.5mm. Also got a new pair of Bessey snips.

I started work on drilling out the holes on the motherboard tray for cable management. I thought that flush mounting the bolts so they couldn't be visible from the front side would look good. Since I don't have the tools to drill precisely 1.5mm in to the aluminum I ordered some aluminum epoxy filler, which should be powder coatable according to their website. Pricey stuff unfortunately.

Epoxy Filler, Aluminum Epoxy, Epoxy Putty, high temperature epoxy - Alvin Products - Metal Restoration and Repair

Thanks.

About 90% done w/ the holes on the motherboard tray. Still need to do the 4-pin connector cables for the pump/fans. But I don't exactly know where it will go yet so it will stay uncut. I won't be using spacers/standoffs for the cable management clamps this time. There will be two plates that go on each set of screws. One between the two layers of sleeving and one on top. Held in place w/ a pair of nuts. The screws will then be cut down to length. Doing it this way will allow for better tension. Plus being able to comb the sleeving since both layers of the sleeving will be separated at each clamp. Didn't realize some of the screws weren't in all the way and were leaning when I was taking the pics. The battery light on the camera was flashing I was in a hurry to get the pics taken. The plan is to cut off all the heads of the screws on the front side of the motherboard tray and use some metal epoxy to flush them. I have ordered some stuff that claims to be powder coatable.

I have also cut all the holes required for the cable pass-throughs. I tried to keep them as small as possible. Each one will definitely require the connectors to be removed for the cables to get through.

Finished the first set of cable retention clamps. Only 14 more clamps to make.

My sleeving combs that I now use to clean and straighten out the sleeving when putting it the case. A good 10x better than those cheap 3 and 4 mod smart ones I was using in the past. Way easier to install and remove and significantly easier to work w/.

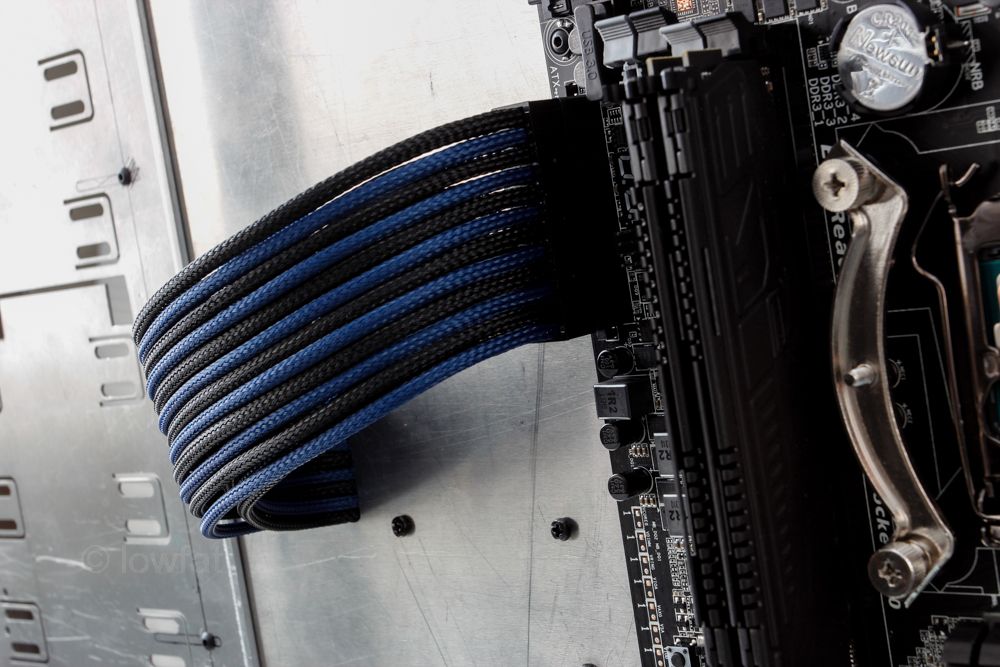

And the outcome. Only took me about an hour to feel the 24-pin one cable at a time through the hole and straighten them out.

Half finished the 24-pin. It is getting very hard to keep the non-overlapping look here. The run is just too long without bracing. I may look in to buying an acrylic comb that sits between the wires.

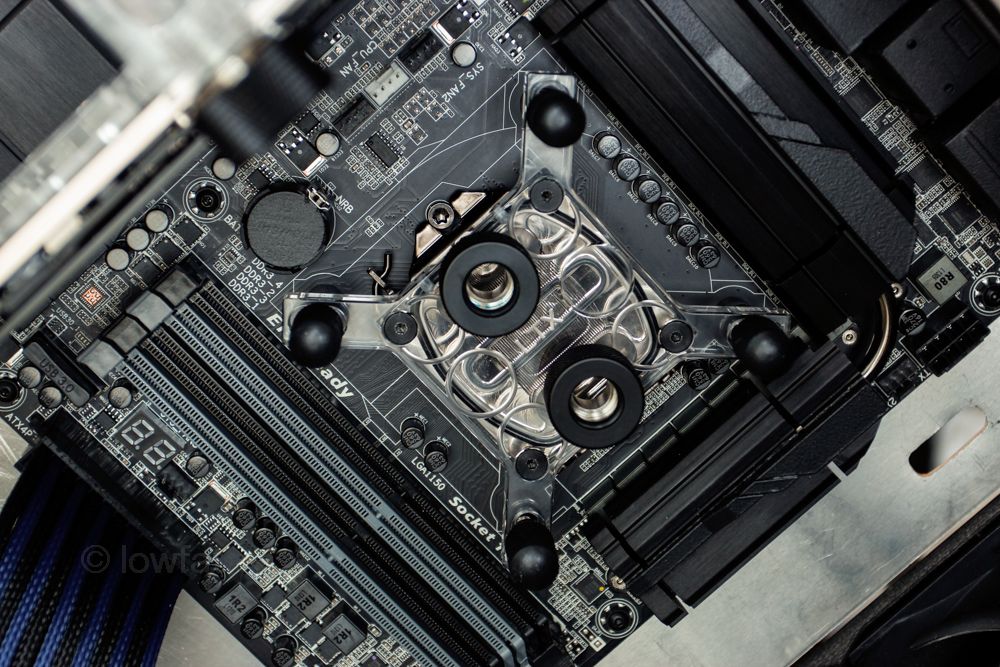

Repolish and resanded the WC stuff. Ended up sanding everything down to 1000 g, then 2000, then the polish.

After polishing

Bunch of pics if the blocks/pump. Ended up removing almost every EK badge. The reason I kept them the first time was due to the fact that the area under neath wasn't finished. After a bunch of sanding it looked good. Although the circles are recessed.

Also painted the caps, the edge of the pcb, the power connectors, and heatshrinked the fan and led connectors.

Frosted a tube. Didn't like it. Looks like I'll be sticking with clear.

Painted the battery.

Love your attention to all the little details. We will never be able to identify all the little things you've done, like painting the CMOS battery, but we'll surely notice the effect on the overall build quality.

Working on the GPU cables and straightening out the cables on the back at the moment.

Really need to get this thing finished. It sucks not having a computer. I am doing all my updates via my HTPC and tablet. Getting close though.

The last days I have worked on the cabling again.

Just need to crimp on some new crimps.

Purolator lady was nice to me this week.

Also got a new SSD. Mushkin Chronos Deluxe 480GB. Immediately took off the label. Love the brushed black aluminum look to it.

Yesterday morning I 'finished' the PSU wiring. That is a first for this build.

Then I started working on aluminum. Cut a new false floor and a frontside 5.25" drive bay cover. Still need to mount them properly.

This wiring is blowing my mind.

Thanks.

Nibbled a new 5.25" side cover. This one is a bit larger to fit the radiator a bit better. Also mounted the false floor properly.

Then I mounted the front radiator.

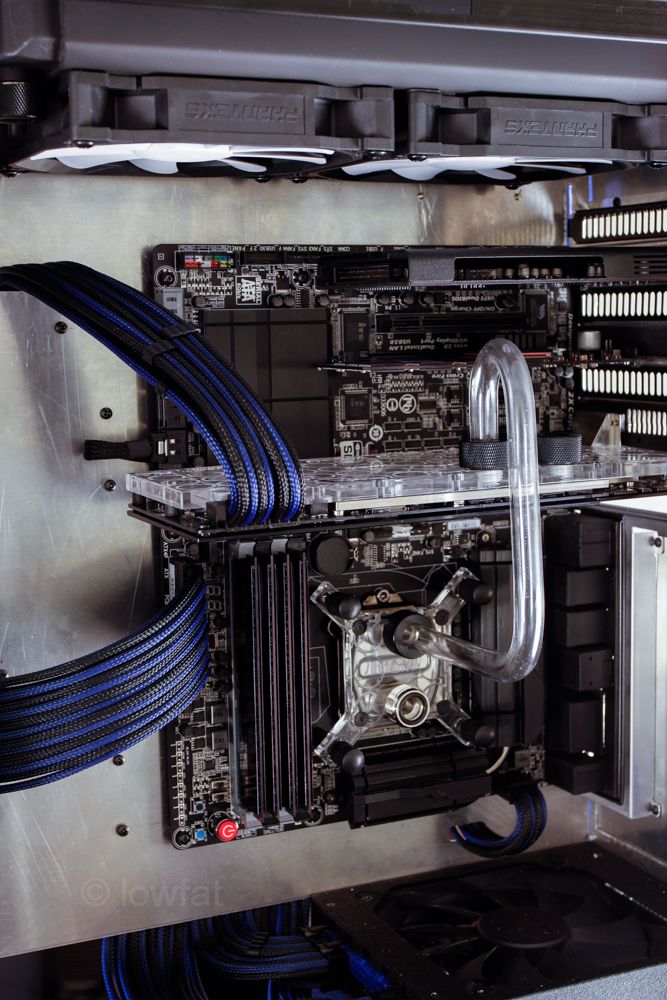

A few pics w/ the hardware reinstalled.

The last few days I have been attempting to use the Monsoon mandrels. It hasn't been going so good. I went through 8 feet doing this single run and it still isn't right. It is 2-3 degrees off.

Some of the work is starting to get tedious. Not much work left but most of it is boring and seems to require a lot of dismantling. Lat few days I have been working on fan/pump cables, filing down standoffs, mounting pump, etc.

Macros of some brass filings.

Mounting the pump.

Pic from the other side of the radiator to show how it is setup.

Got bored and heatshrinked my entire screw driver.

I have question: are you going to eventually poweder coat/paint interior of the case?

Personally I think that clean raw aluminium, even with all those scratches looks good, and more original than most builds these days, since cases just come in finished form (everything is black).

Bookmarks