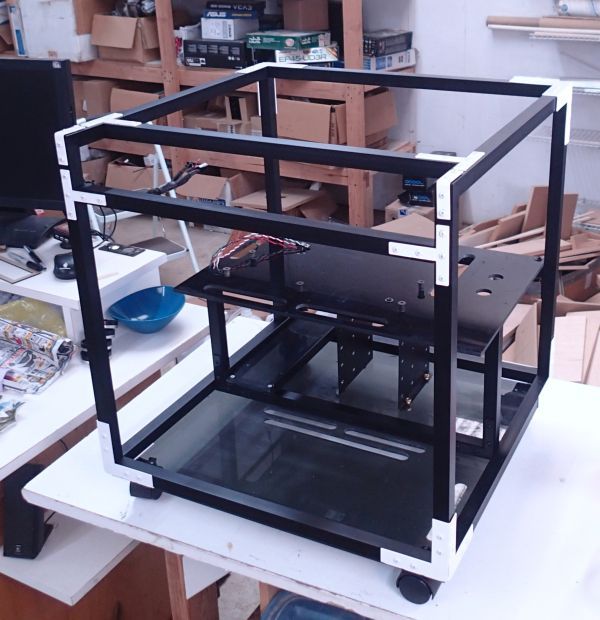

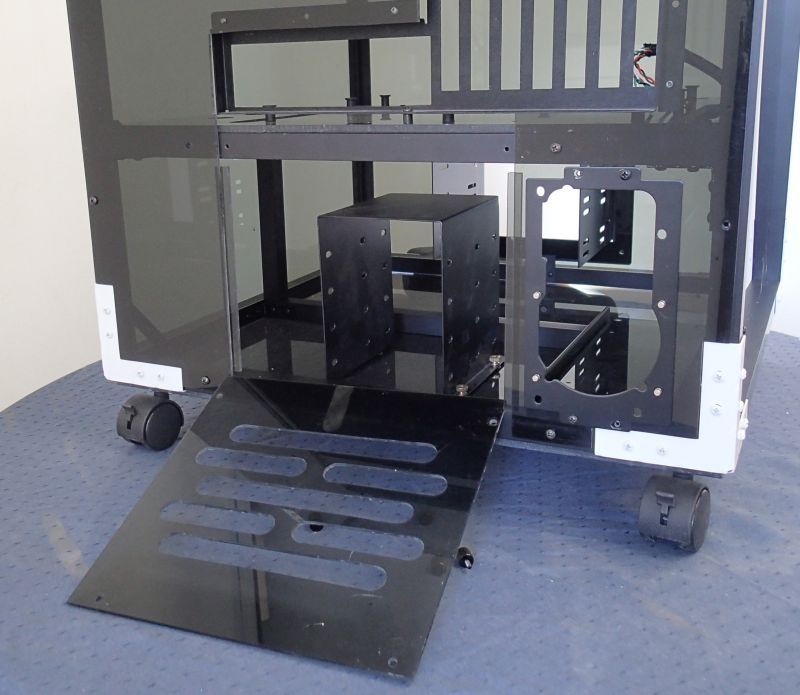

Exoframe 2.0

A few years back I built my Exoframe Project.

Build log is here.

Completed project thread is here.

I was recently contacted by GMdoubleG at the ocforums about possibly building a similar case. I told him that I could, but it would take a while because, as I mentioned in the original thread, Iíve always wanted to build stronger 3 way corner brackets from steel.

Well, I contacted some local NorCal guys, Erik at Norcal laser and Matt at Mioneís Solidworks, and after a few revisions, I had a steel 3 way corner bracket.

The thread on the design and fabrication of my 3 way corner brackets is here.

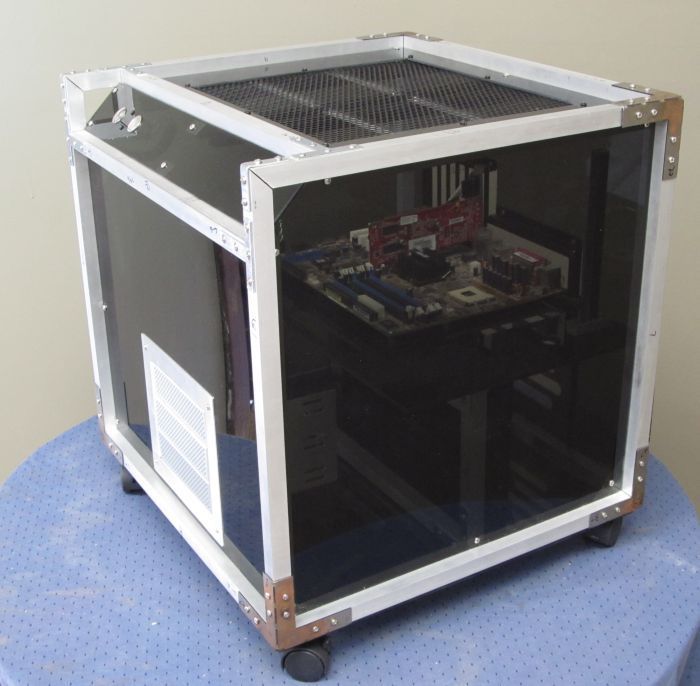

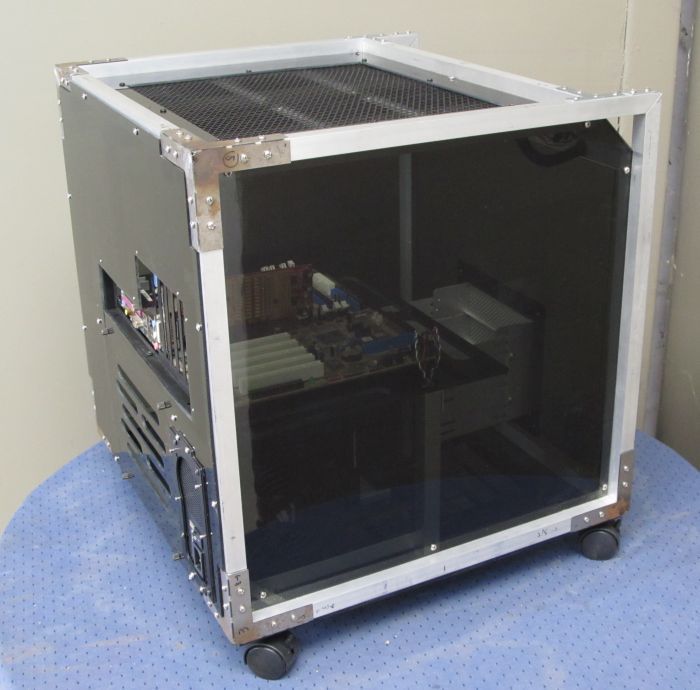

GMdoubleG had some specifics.

Looking for more of a cube shape. Horizontal motherboard. Two 2x120mm radiators up top.

Plan was to leave the aluminum bars and steel corner bracket unfinished--he would have a local painter powdercoat and/or anodize.

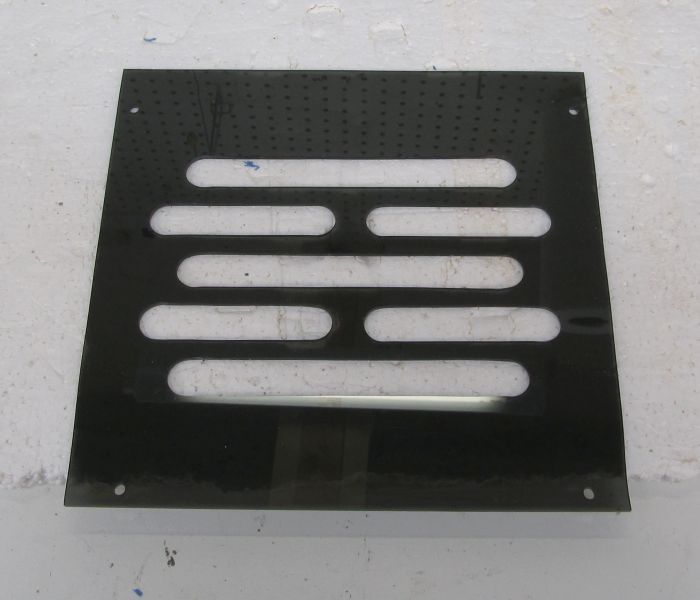

Going with all gray plastic paneling.

He passed along some general design drawings:

Reply With Quote

Reply With Quote

Bookmarks