There is a case perfectly suited to LC?

Meets your expectations,

with options ATX, inverted ATX or upside-down configuration?

That in which everything can change no problem cutting and completely modular components ...?

One which ignores the AC at the start and will not be compromised?

NO

Usually the case designed for AC

should be modified to work with LC

There is no ideal and a matching each of us case.

There will never be ... because everyone needs something different.

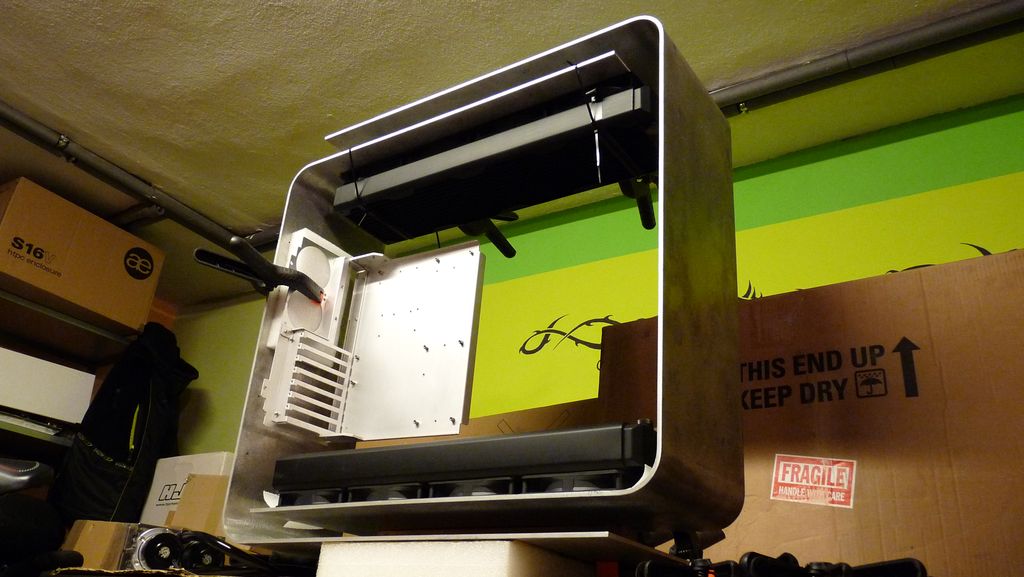

Here's my vision, rugged in design and simple in its form ...

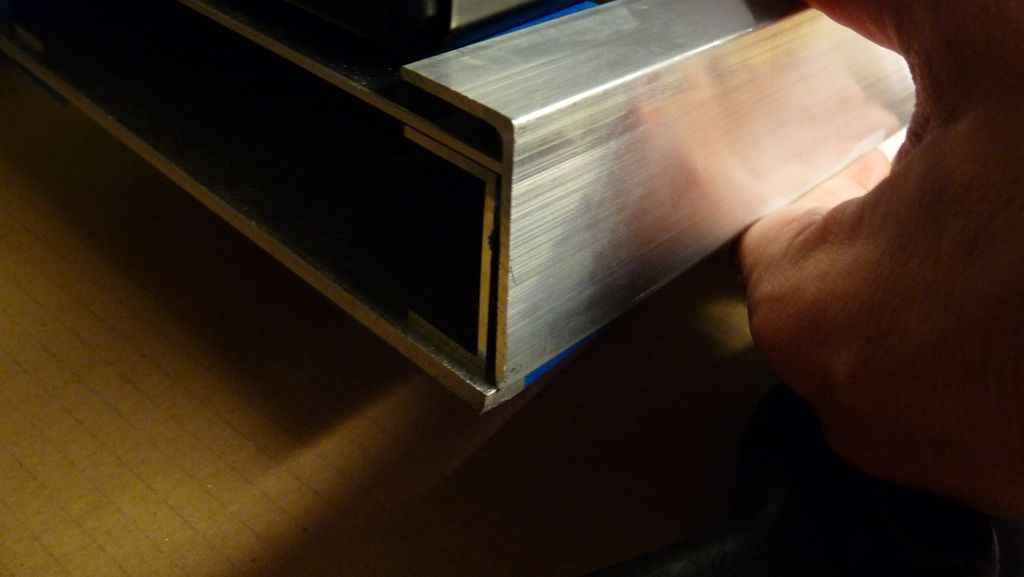

Panel from the visible side is a sheet of glass cut with water to the desired shape.

This solution requires an absolute order/clean in the wiring and equipment inside.

Everything is visible... and there is no room for error.

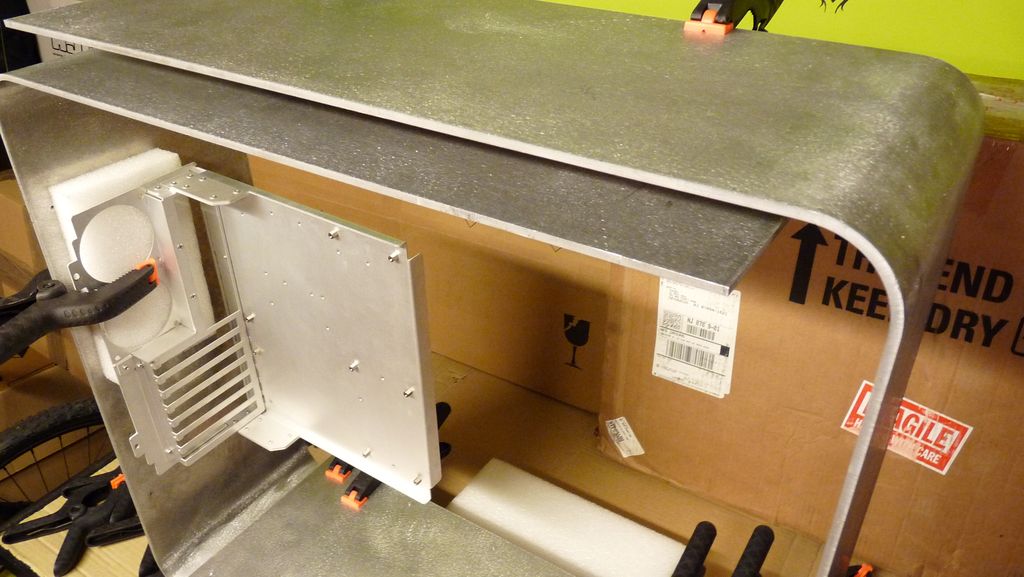

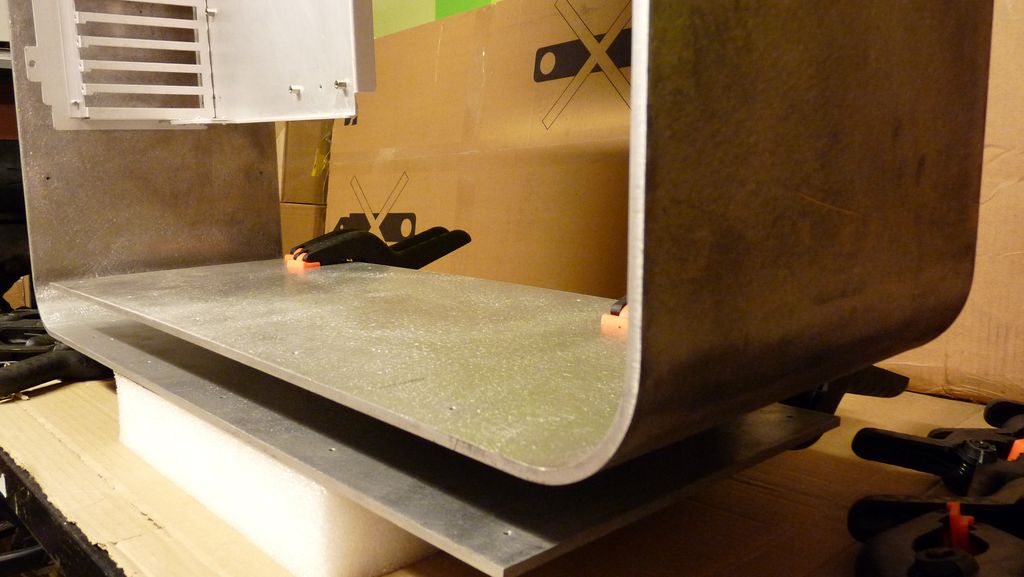

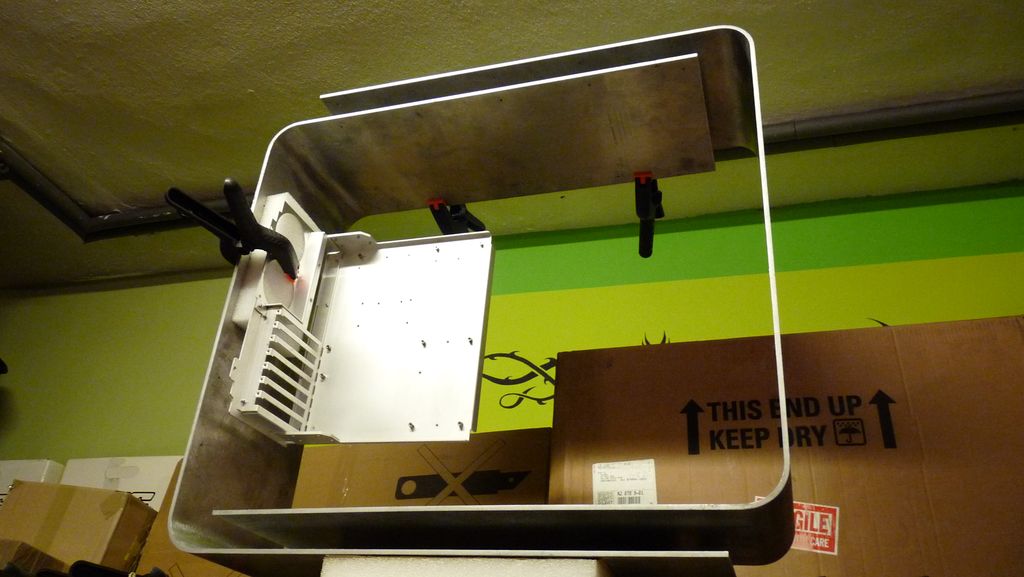

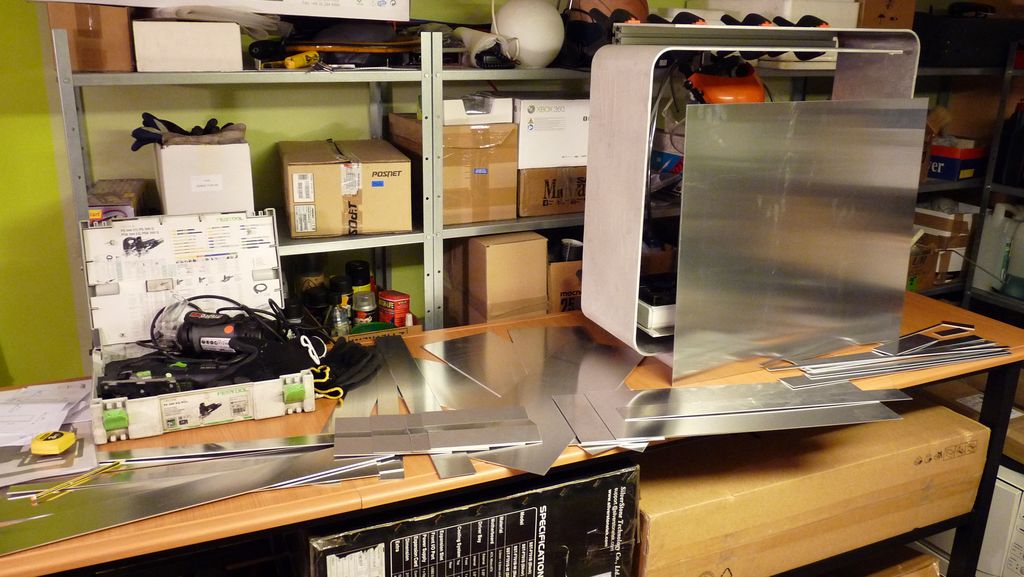

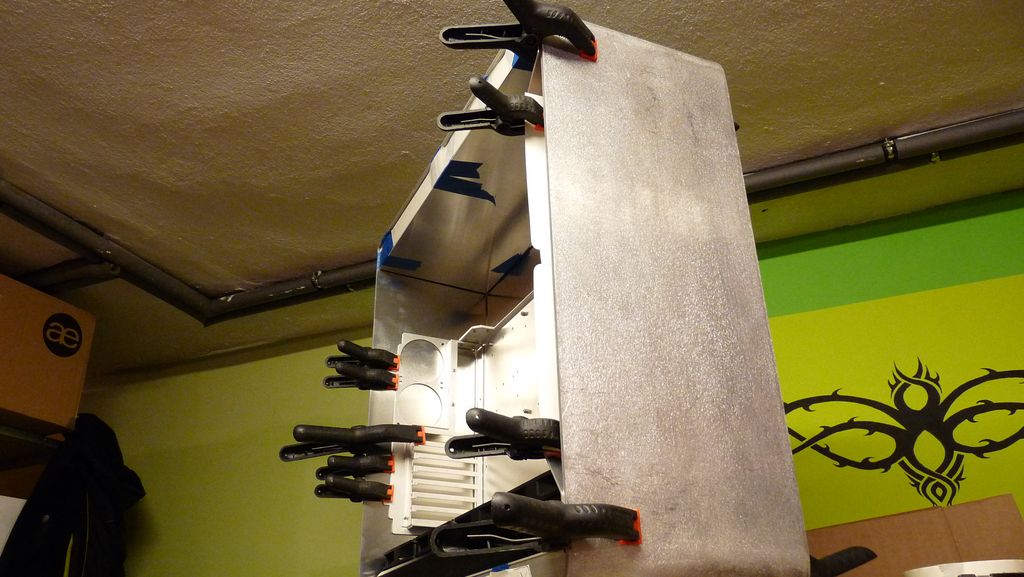

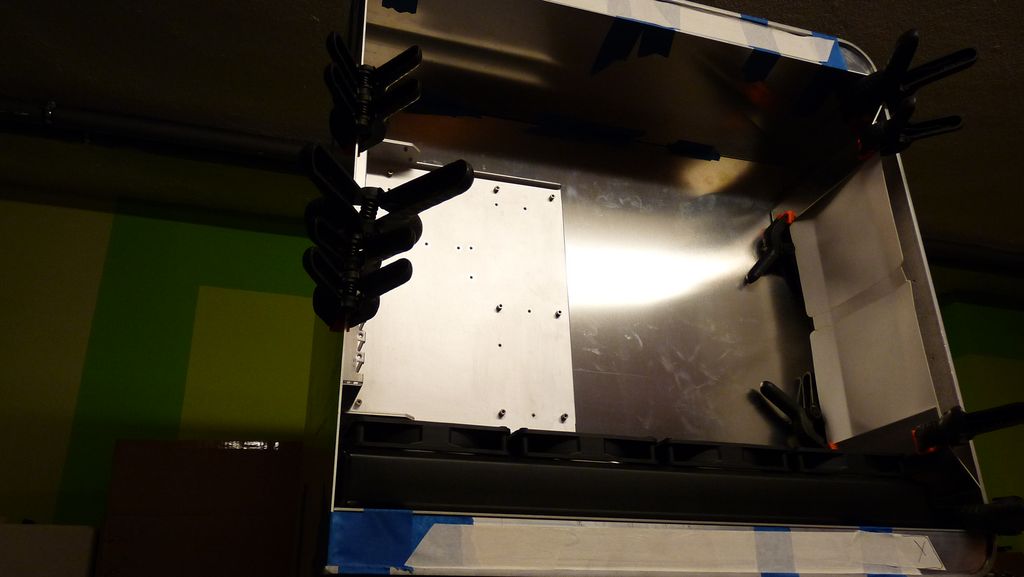

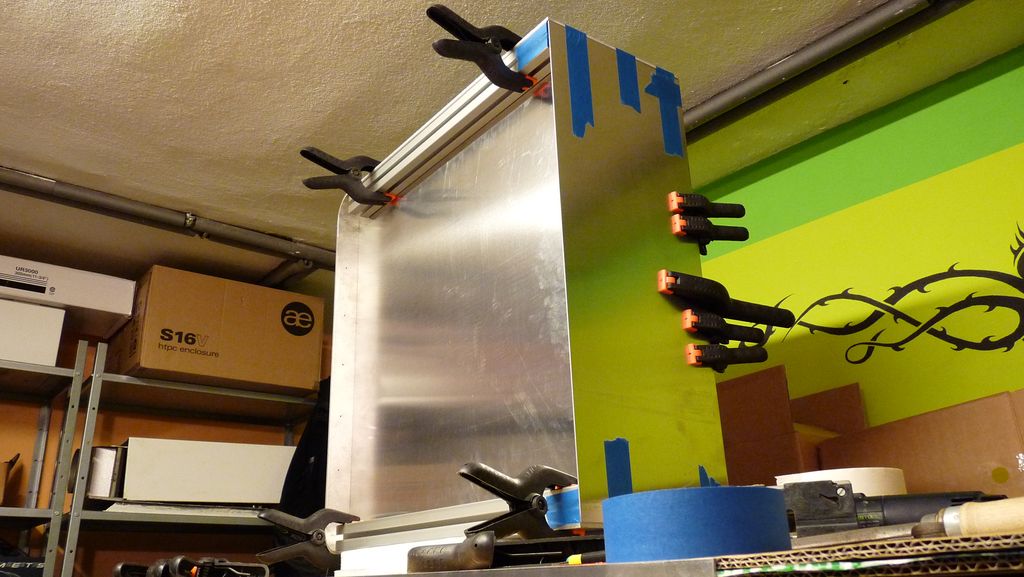

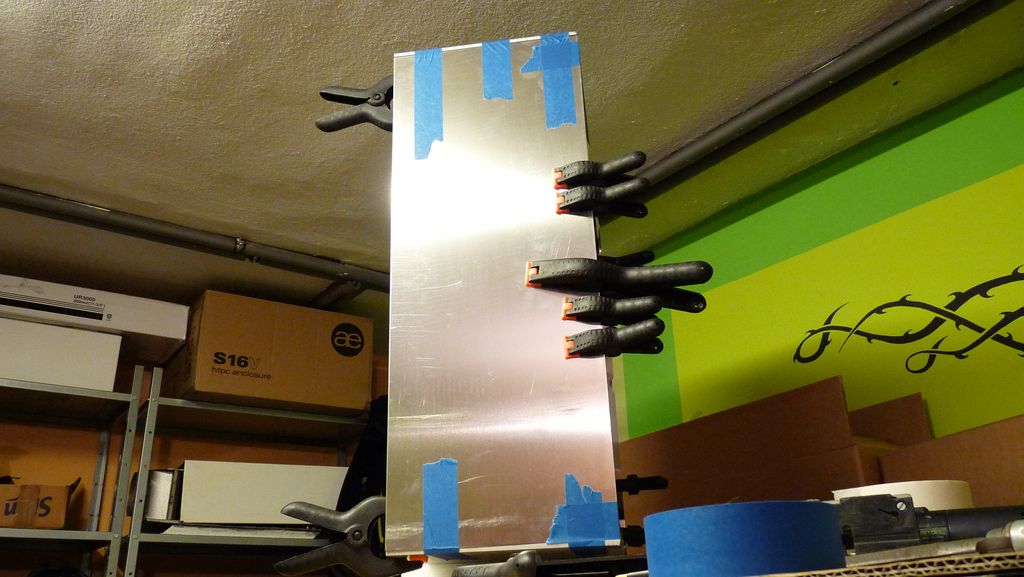

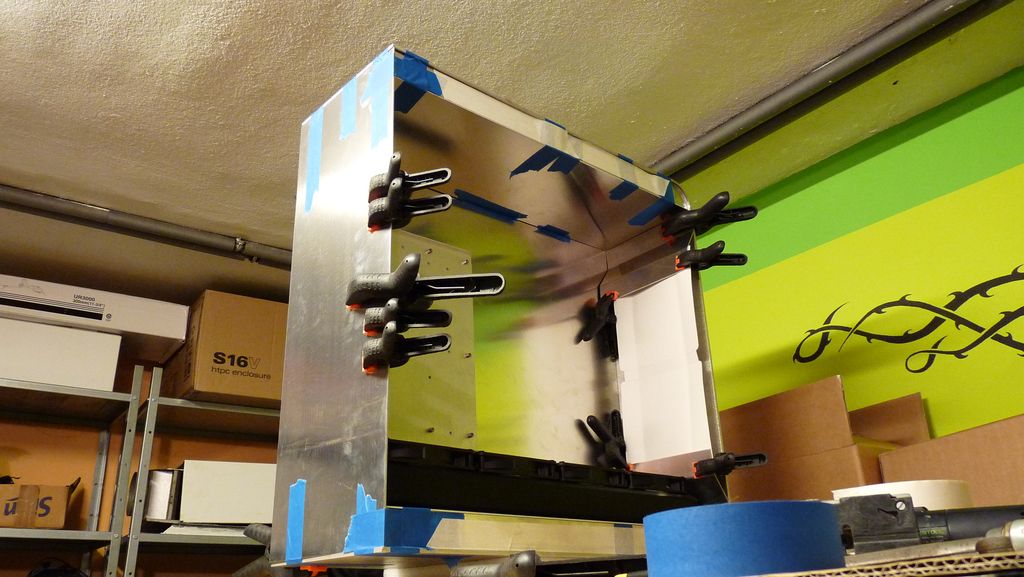

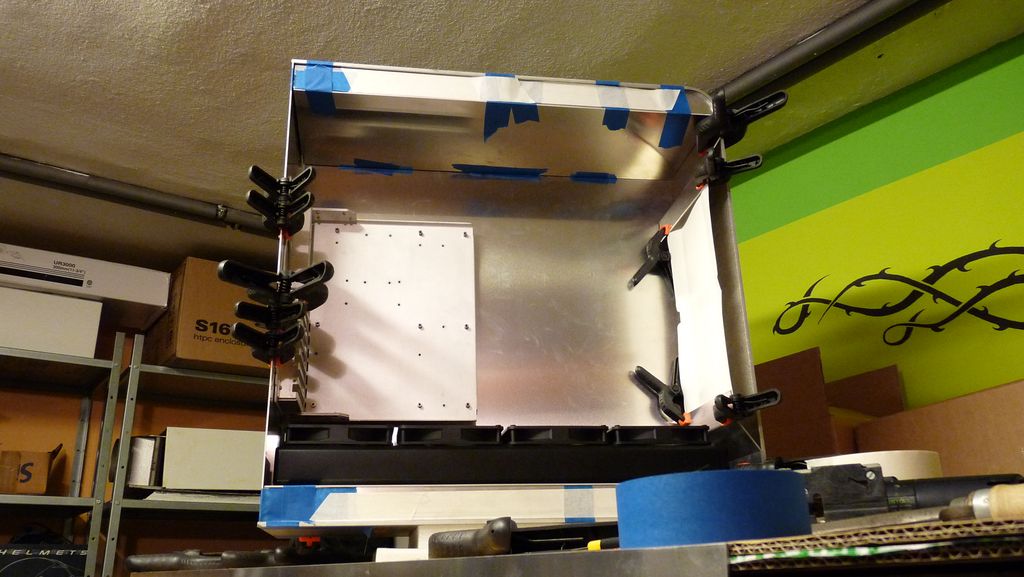

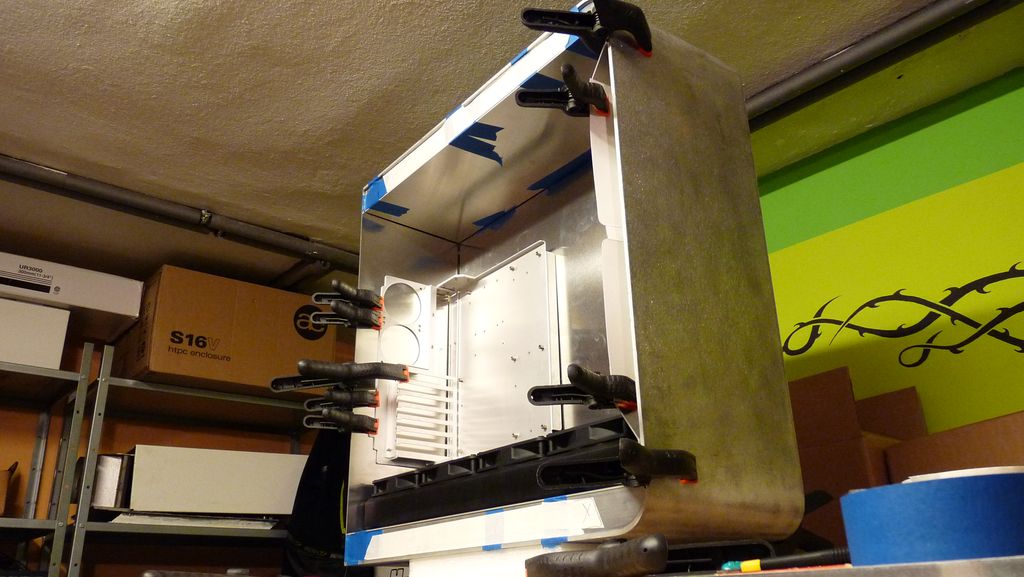

Unibody.

Solution like in Temjin TJ07, expensive but providing extraordinary solidity / rigidity of the structure.

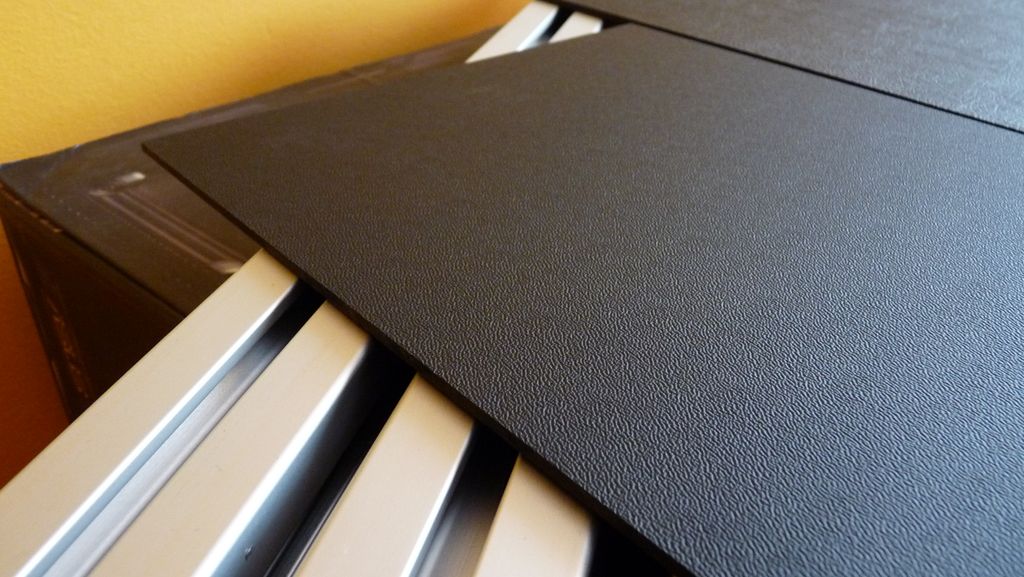

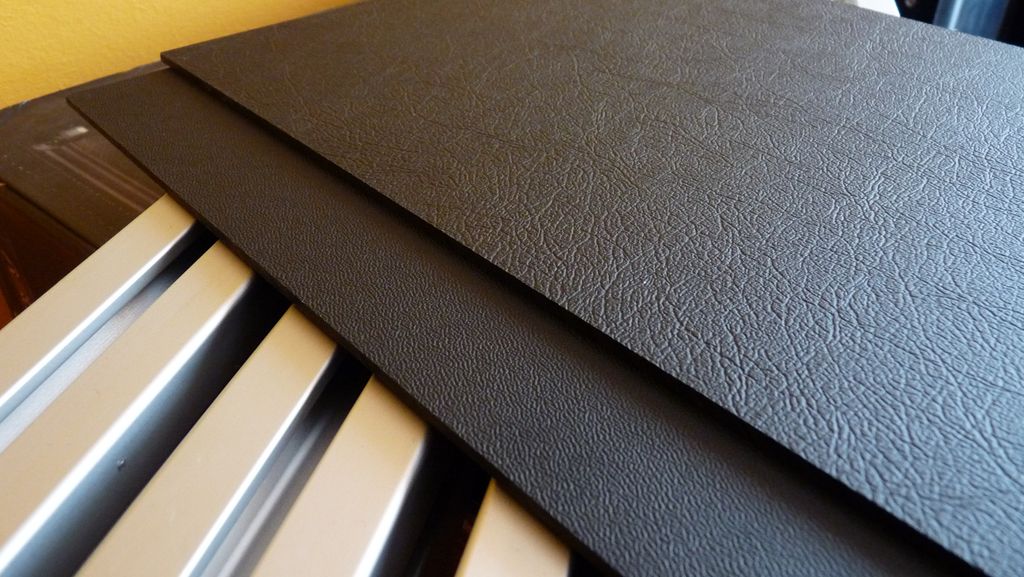

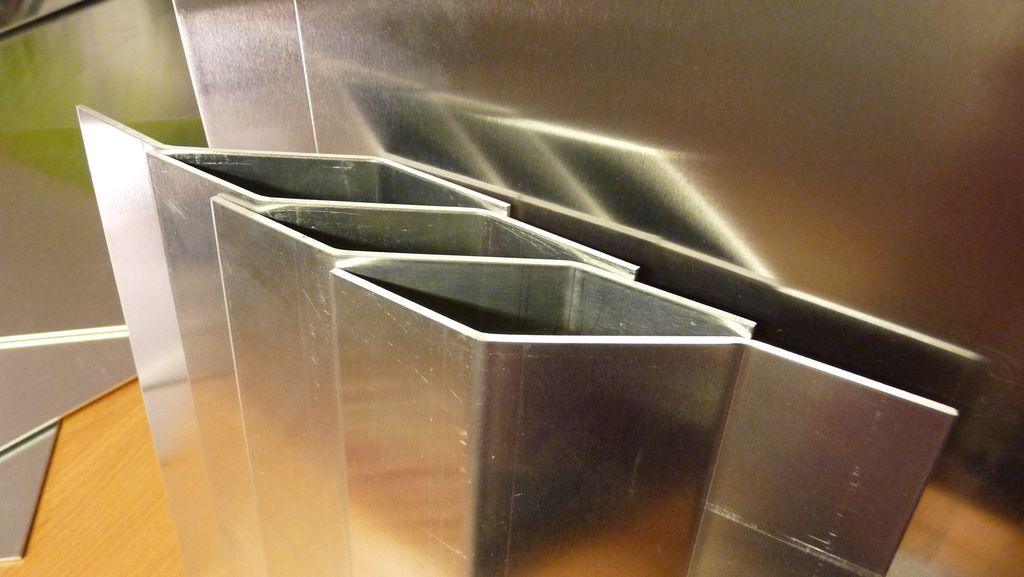

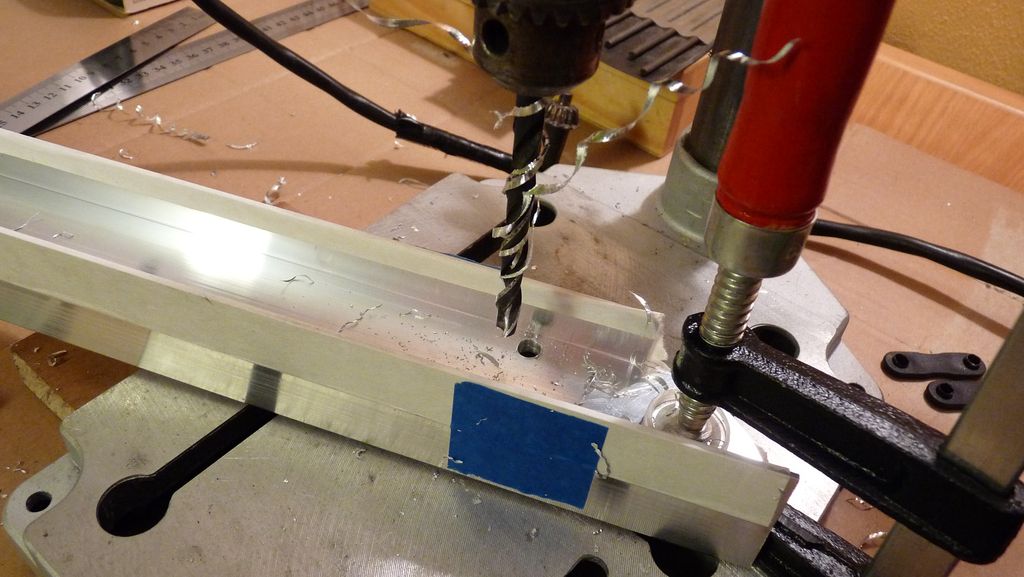

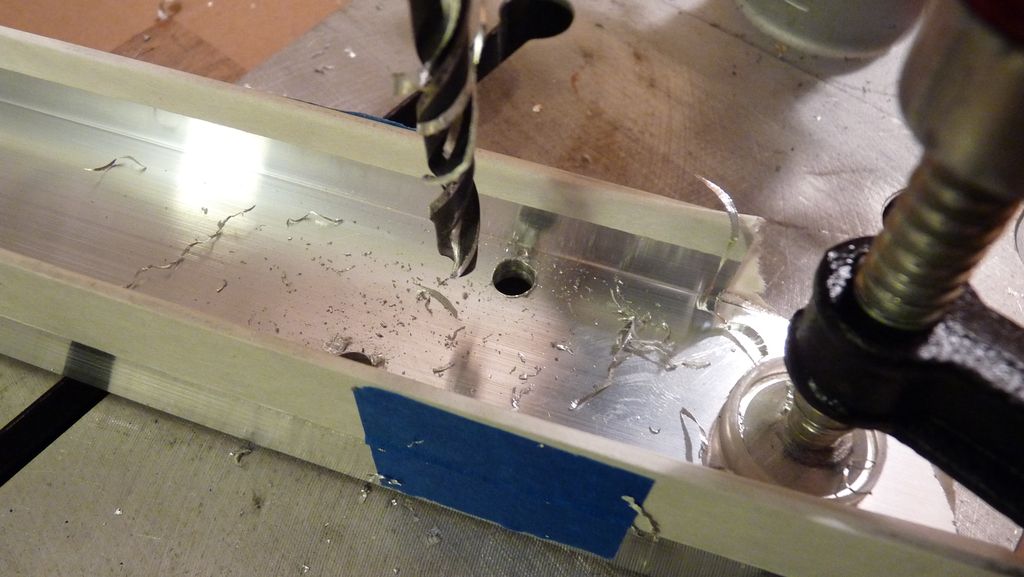

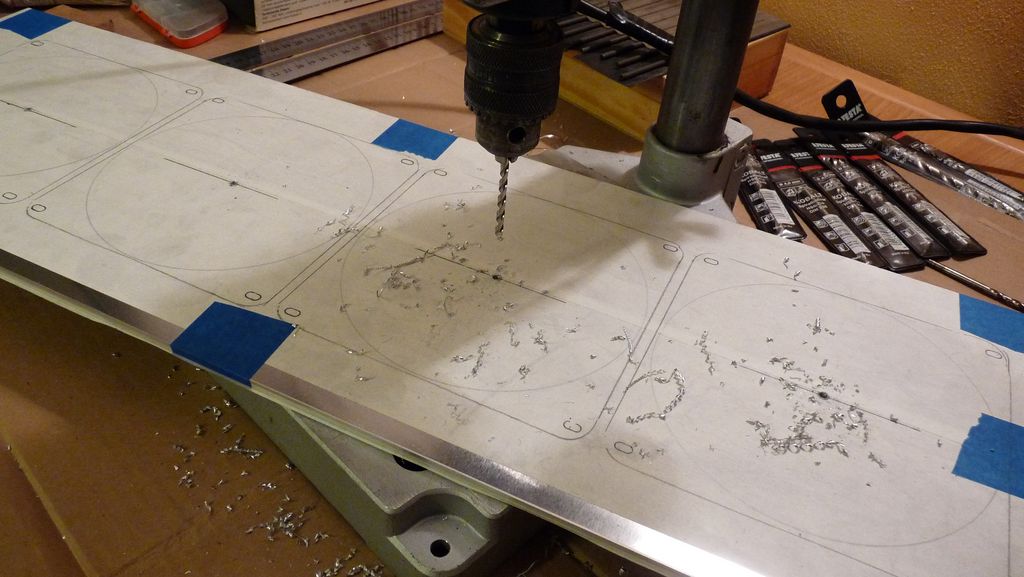

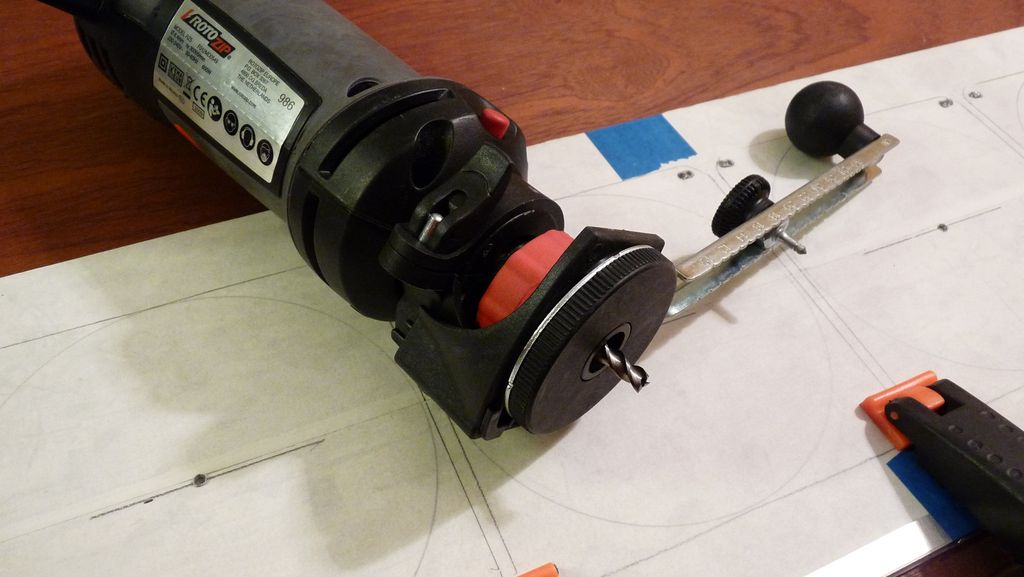

Aluminium 5mm thick.

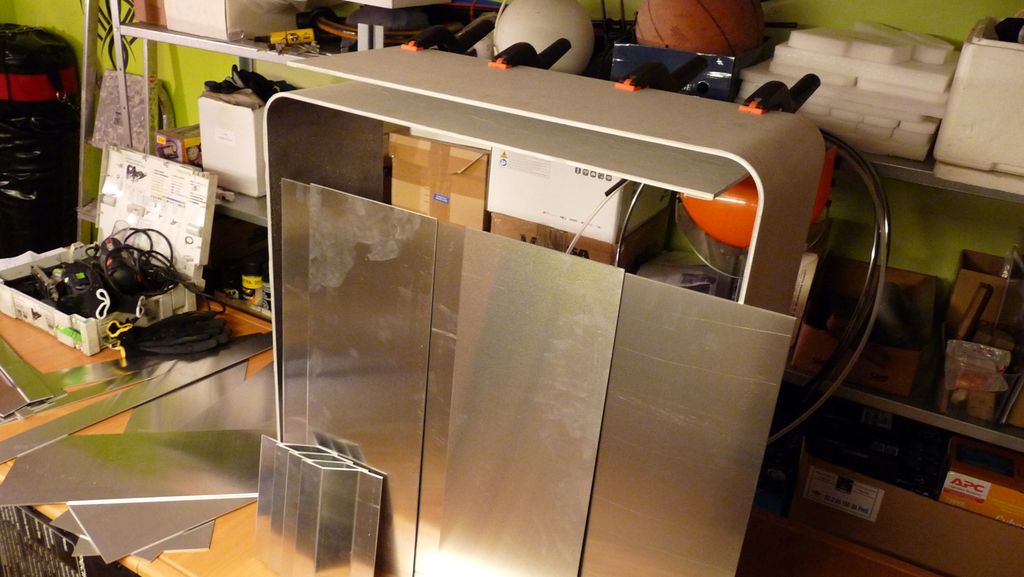

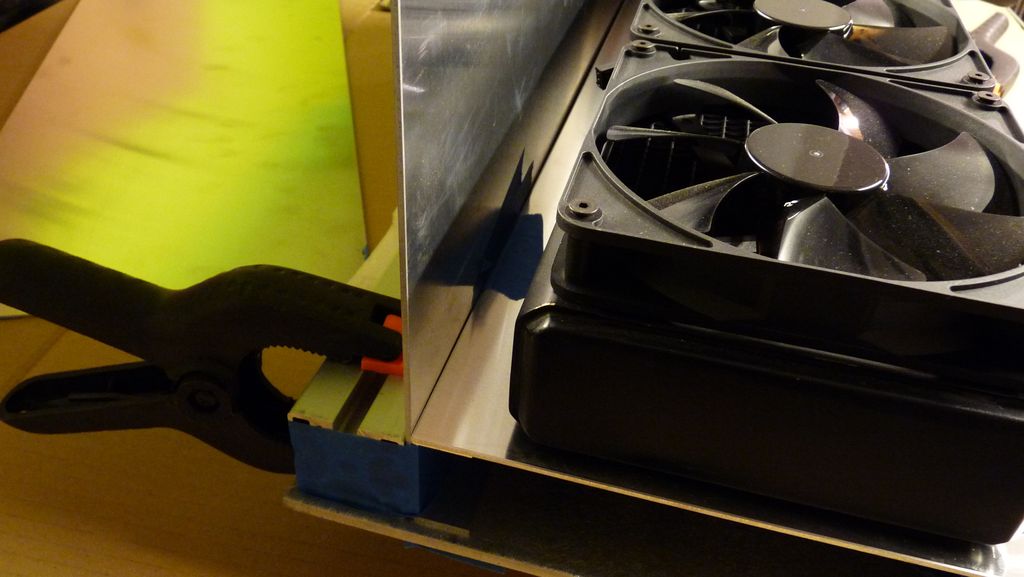

Rads and power supply are placed in boxes.

This interchangeable elements whose assembly / disassembly takes a while if necessary.

I used the locking system identical to that encountered in the Lian Li (HDD cages).

The rear wall is also a removable element, option 7 or 10 IO depending on the version of mobo.

The second side surface with slots that are part of the supporting structure is made of 5mm aluminum.

After twisting the body gives it exceptional rigidity and strength.

There is no room for bending like in my other case... TYR X-500: D

[b] Hard as rock ... no compromise [/ b]

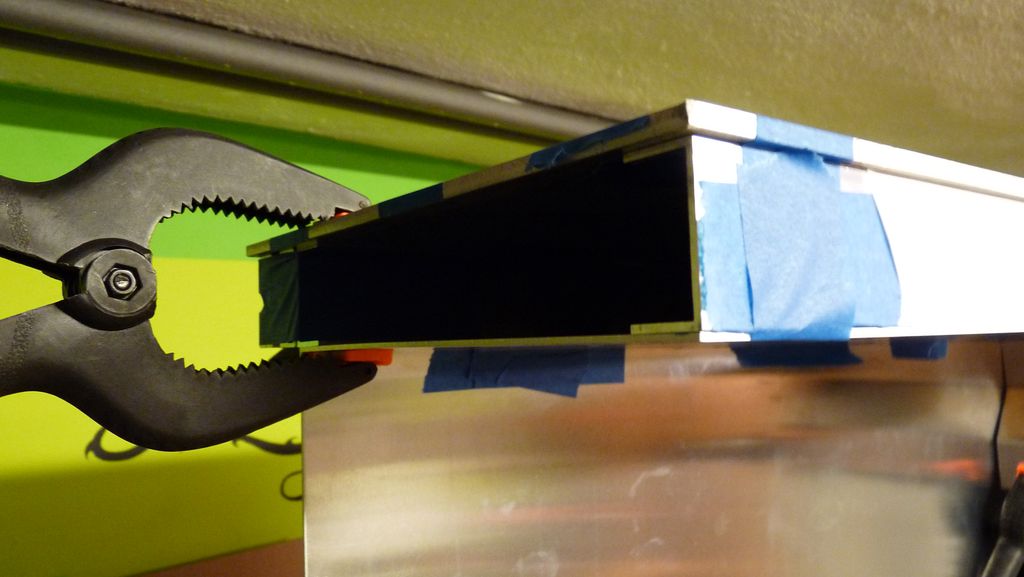

Rads covers act like a solution in the Silverstone Fortress FT02.

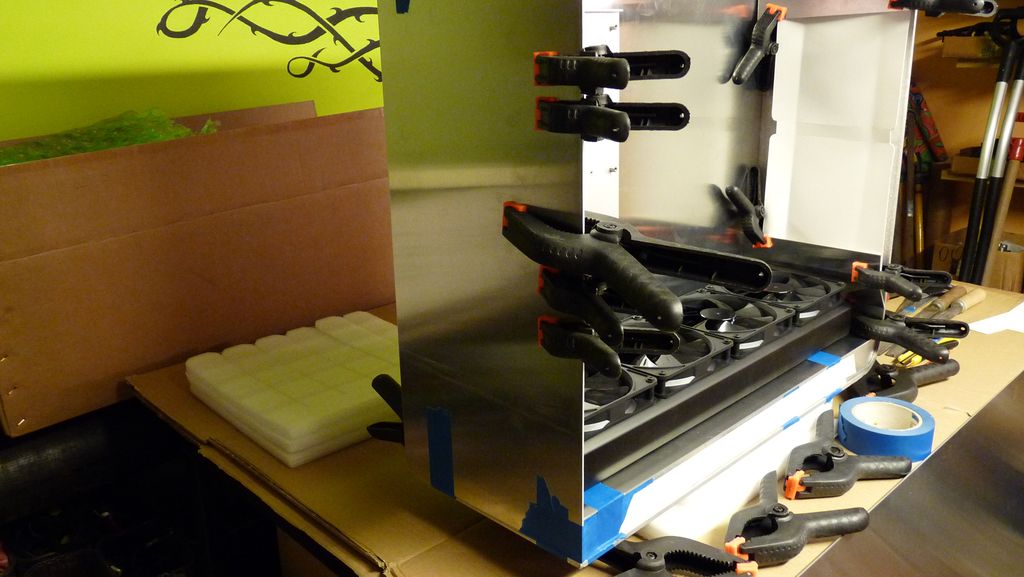

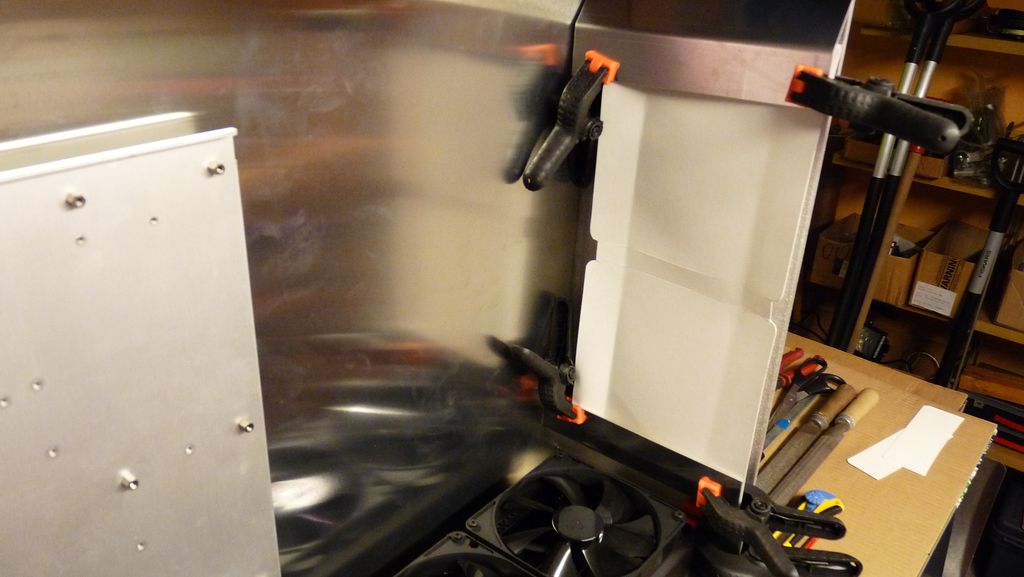

Here you can see rapid fixing system

allowing removal of the rad cartridge for fan cleaning...

if necessary.

This option requires the use of connectors such as Koolance Quick Disconnect

so as to facilitate removal without loss of fluid / drainage system.

One more thing ... rads covers can also be a version of 3x180mm (Magicool),

It's just a matter of cut appropriate holes.

I want to make two versions ... 4x140mm and 3x180mm.

I think what else is needed ...

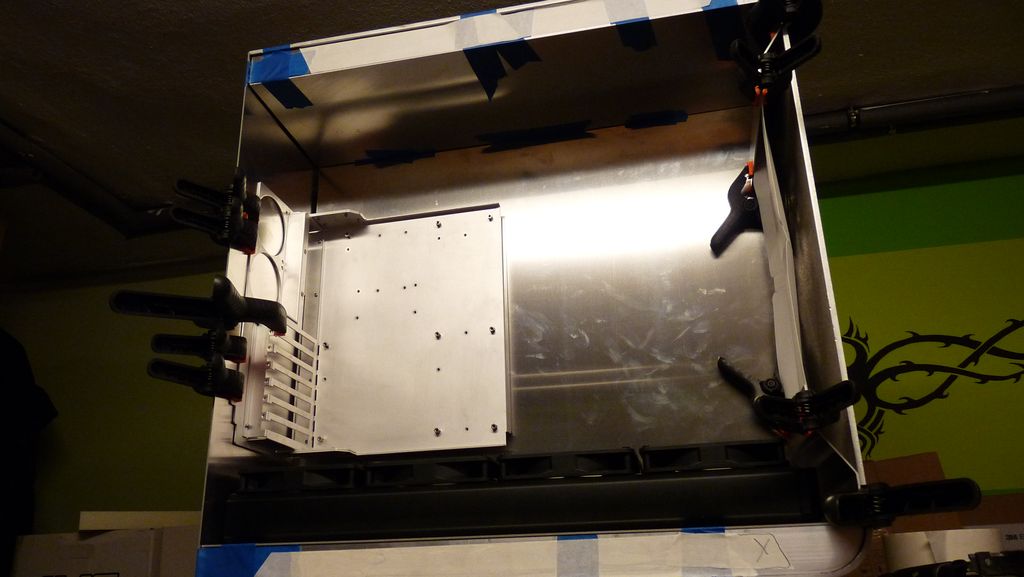

Current status of the project does not show solutions for cable routing

and to include SSD and HDD on the inside mobotray.

Mobotray for the first three prototypes already have.

I just used the slide mobotray Cooler Master

such as the Wave Master and Praetorian ACT-200.

CDROM drive is an external USB version.

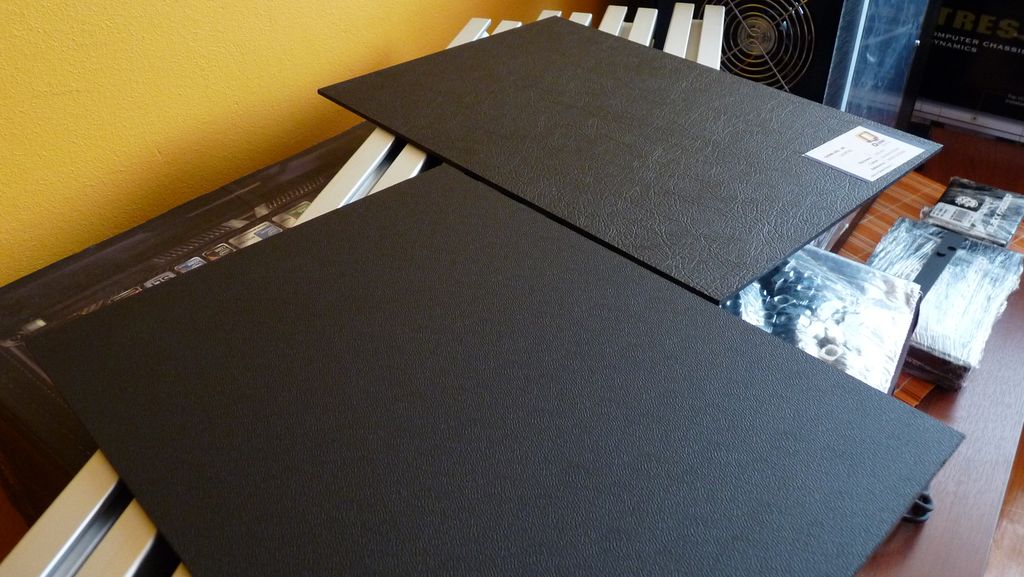

As for the surface finish is [b] Black Wrinkle [/ b] in the basic version

and black brushed aluminum in hi-end sufrace.

Unfortunately, surface finish second option is expensive ... and it very much.

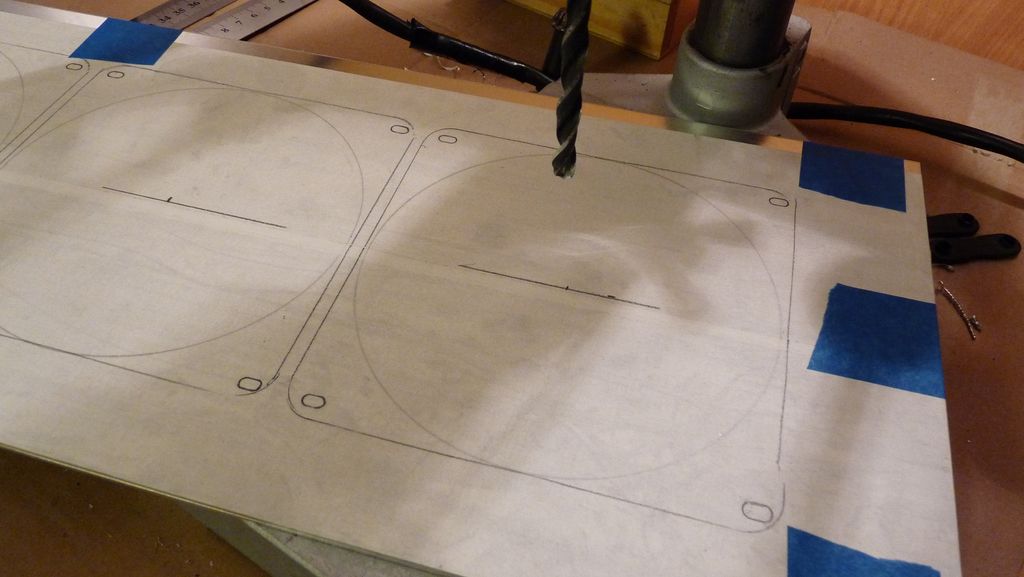

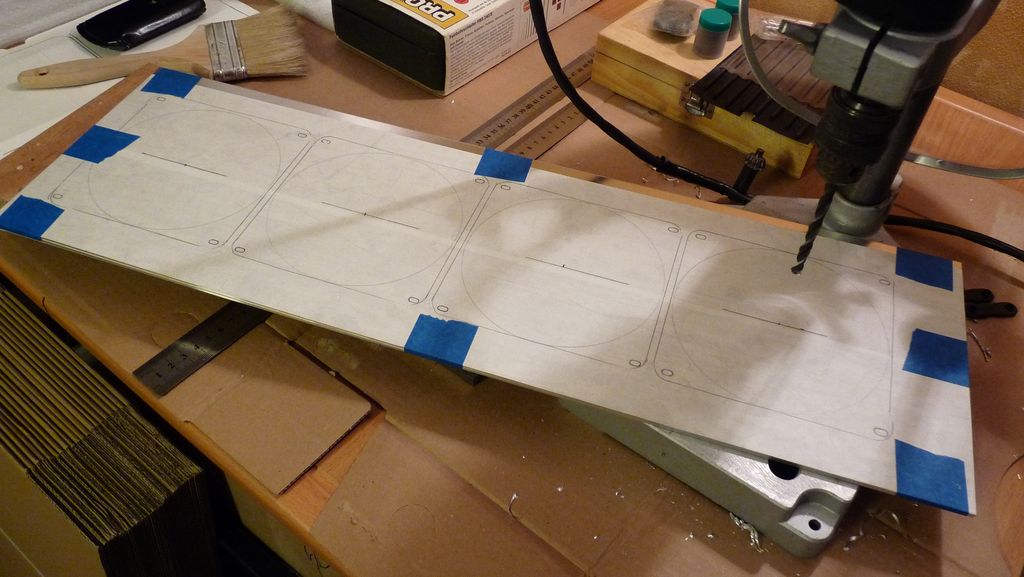

CAD design is ready ... time to complete prototypes.

But before that I will think about the details and resolve the errors.

No one is infallible.

If someone wants to share his impressions and thoughts about this project

I will be grateful.

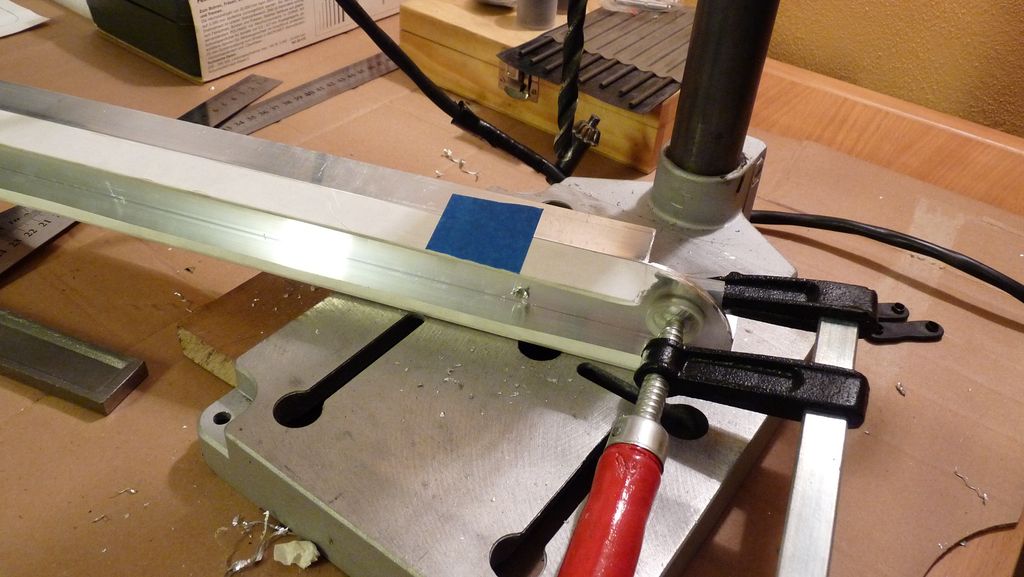

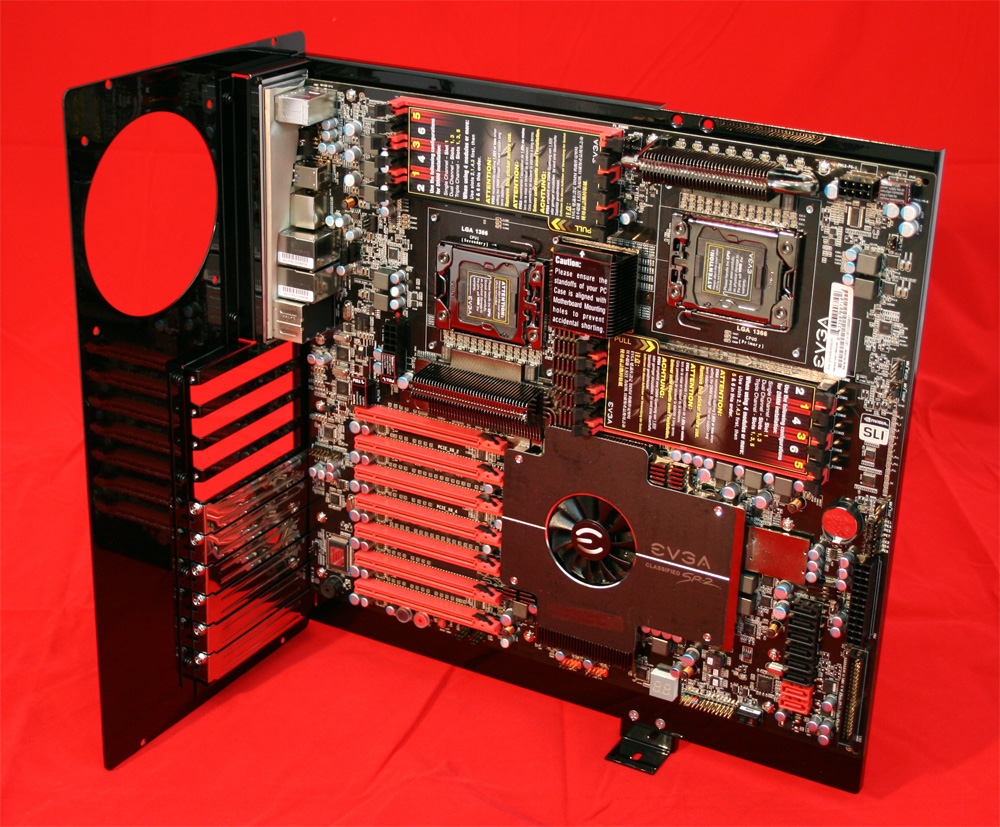

In the end ... some pics of the current configuration.

Obsidian 800D is too small to accommodate two SR1 560.

I decided to find a solution.

Reply With Quote

Reply With Quote

Bookmarks