2:00 PM PST - Arrived from Performance PCs

4:00 PM PST - Testing has begun. The competitors will be the Apogee XT Rev 2, EK Supreme HF (latest version), and the XSPC Raystorm. (Sorry, I dont own the Koolance 370). The Apogee HD has multiple outlet ports, but initial testing will be with one inlet and one outlet, like any standard CPU block.

9:00 PM PST - Xavier, an undergrad engineering student in my lab has completed the first round with the Apogee XT Rev 2.

10:30 PM PST - Few photos:

The opening

Closer view of the block and back plate

View of the internals

Hydrodynamica - The system the Apogee HD is going in if it wins out on top. Currently not using my dual loop config thanks to the messed up 452X2 reservoir.

Side by side with the Apogee XT Rev 2, that it will be competing with to gain a place in my home box

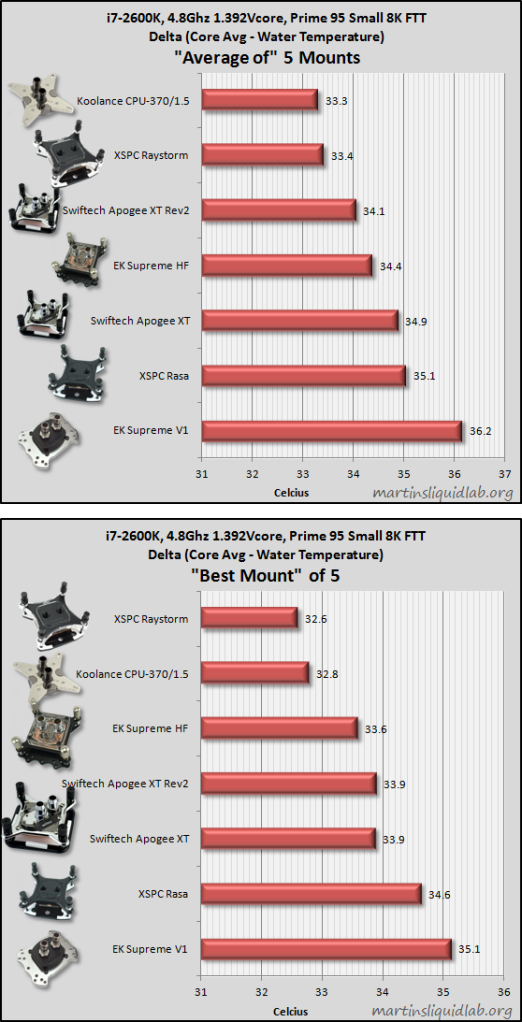

Below are prior testing results posted by Martinm (he has not tested the Apogee HD yet). Keep in mind the top graph below. The best of five mounts graph is not as useful. I have serious doubts about the results released by a few other testers concerning data they obtained for the EK Supreme HF, so I might make note of that further on down.

We will see how great the deltas are tomorrow and their correspondence to this previous work.

1:10 AM PST - Testing has begun on the Apogee HD. Gotta say, everyone has their own preferences, but I liked the chrome look of Swiftech's previous top blocks. I am not a big fan of matte black finish or the much, much uglier white top version that you can order instead.

11:00 AM PST - Testing is ongoing. A few notes regarding accuracy and block versus block direct comparisons:

Two or three people who like test and publish their WC reviews here before have complained that it is hard to measure the latest round of blocks due to their sameness, difficulty in preparing the test setup and statistical outliers. No disrespect to them, but it isnt. (doing a waterblock test is a joke compared to calibrating a laser interferometer for LIGO) They are just forgetting to control a few variables in an N variable problem, where N -1 must remain unchanged. Unfortunately, with many do it yourself testers (including, comically, those who work for the block companies themselves), they have two or more variables varying from test to test, essentially making the high precision of their results void. What are the main N variables for a waterblock test ? They are:

1 – The static block itself

2 – The TIM

3 – The ambient air temp

4 – CPU speed and load

5 – Water quantity (same as saying loop size with reservoir)

6 – Head pressure

7- Flow rate (Dont forget Bernoulli)

8 – Socket force (from the ILM)

9 – Block attachment force

There are a few more very minor variables, but since we arent writing a research paper of 90 pages, this will suffice for now. So, call block testing a 9N problem. With some given loop A (unchanging with the same pump) in some room B (ambient unchanging) with some motherboard C (unchanging) and some processor D (unchanging) using some thermal material E (unchanging) with some block pressure F (unchanging), then only the block choice will change. But take note of variables 8 and 9, cause this is what trips up most testers.

The difference between a Swiftech Apogee XT rev 2 clamped with 190 N (Newtons) is compared to a EK Supreme HF clamped at 240 N is a void result. Which is basically an artsy fartsy way of saying that most testers are not correctly accounting for the force and pressure in which they screw down the block. And after all, how could they be ? Each company has their own sometimes wonky attachment method where it is impossible to measure precisely the force applied or the pressure distributed. The cross product (r x F) torque they apply to the thumb screws has no applicability from one setup to the next. It is usually done by 'feel', Without this variable fixed, one tester will see the EK Supreme HF beating the Apogee XT Rev 2 by 0.9 deg C and another testing, using the exact same bench table, but starting over, will see the reverse.

The difference of 50 N is enough to smear the results almost 1 deg C. (exact calc to follow after lunch)

This is why you see the see sawing results from one review to another. Of course the better testers, try to do five mounts or ten mounts, etc... but still what is tight for one clamp assembly may be loose for another. So you are back to apples and oranges.

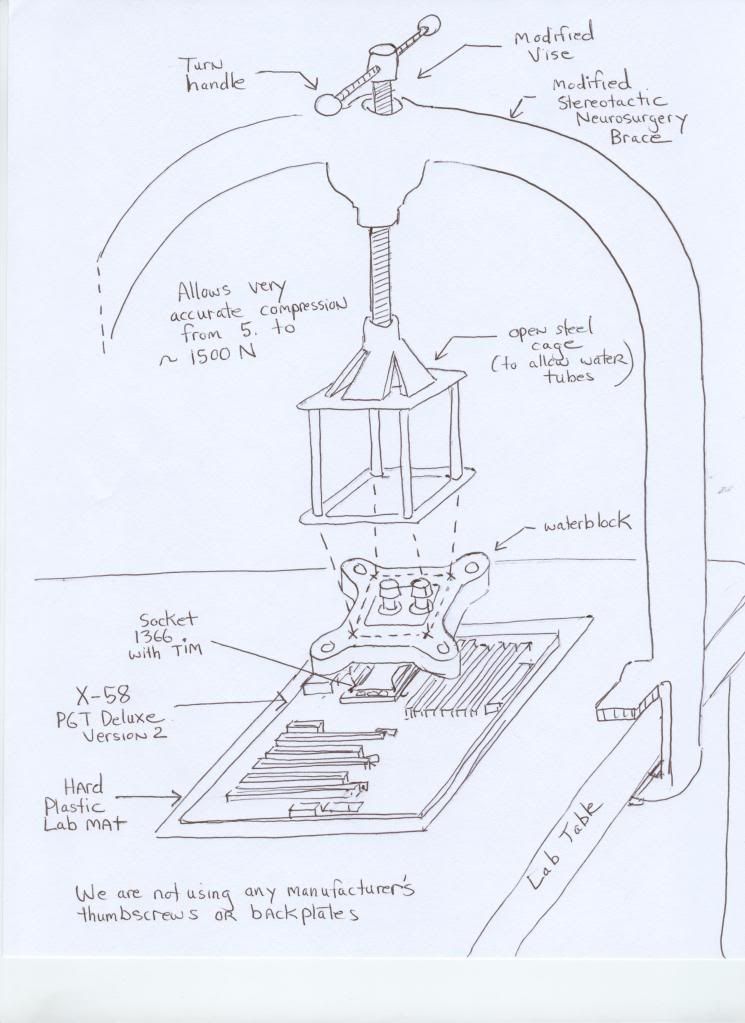

So measuring the various blocks heat release ability is actually fairly easy if you account for everything correctly including block attachment force. And that is why we need a lab made rig to correctly apply force to the blocks, to get exact results.

3:40 PM PST - Testing is ongoing. Results later tonight I am hoping. Here is our test setup which has changed a bit:

Simple loop (open air, not in a case) in our back lab room that stays at 27 deg C, with a trusty Asus P6T Version 2 board and an Intel i7-980x processor at 4.4 GHz. The loop consists of the following - Swiftech MCP655 vario on setting 5 (4800 rpms) -> one foot of 1/2 inch ID, 3/4 inch OD clearflex tubing -> for this loop we are changing to the XSPC RX 360 rad with Scythe S-Flex E fans blowing at 1000 rpms -> one foot of clearflex tubing with a Koolance quick dis-connect in the middle -> 980x CPU with block custom clamped to maintain same even pressure (in Pa) -> one foot of clearflex tubing with a Koolance quick dis-connect in the middle -> Swiftech micro-res filled to about 10mm clear of the top and fully bled -> one foot foot of clearflex "" back to pump. The TIM we are using for these mounts has been changed to TX-2. The mix we use is always 100 percent distilled water with 5 drops of algae biocide from Pet Smart.

The same motherboard and processor are used throughout all the block mounts. By pre-measure, we found the ILM to be applying ~ 523 +/- 10 N of force with a pressure of 3.19 x 10^5 Pa (319 kPa) over a roughly 40mm by 41 mm area. Using our custom water block press, we apply exactly 240 N of force with a pressure of 1.07 x 10^5 Pa (107 kPa) over a 45 mm by 50 mm area. To give non science folks an idea of the force we are talking about (ILM plus water block), you could use the mental image of an 85.7 kg person (189 lbs) standing on a bare processor without it being in the socket.

10 PM PST - Tests finished

It is like Kurt Russell said in the movie The Thing; It is time for us to find out who is a poser and who is da bling bling.

Results:

(Notice we dont really have to do multiple mounts since each we apply the same even 240 N of force. But, we are doing three mounts per block, just to account for TIM smearing and even coverage). I will give all the full test methodology and data tomorrow.

Results listed by block release date:

(this is core average – water temp with the i7-980x at 4.4 GHz at 1.45 vcore running Prime 95 small 8K FTT) (I am using the same Dallas one wire sensors used by Martinm so that we can compare our results to what he found previously. Thanks go to the Chem Dept who were kind enough to loan me some stuff.)

Name / Mount 1 / Mount 2 / Mount 3

Danger Den Maze 4 / 42.2 / 42.0 / 42.0

Swiftech Apogee XT / 40.0 / 40.0 / 40.0

EK Supreme Jet HF #6 / 39.1 / 39.0 / 38.9

Swiftech Apogee XT Rev 2 / 39.0 / 38.9 / 38.9

Koolance 370 / 38.7 / 38.7 / 38.6

XSPC Raystorm / 38.1 / 38.0 / 38.0

Swiftech Apogee HD / 38.1 / 37.9 / 38.0

So wow, basically a tie between the Raystorm and the Apogee HD. But the Apogee HD has a better mounting mechanism. And the the Raystorm has better flow I suspect. But the Apogee HD has multiple ports. But the Raystorm is cheaper.

But, ….but, …... but, #$%! my head hurts. Let's wait till the flow data comes in over the weekend.

This Apogee HD block is better in temp and I suspect flow (test tomorrow) than the Apogee XT and XT Rev 2. As to whether you need to pay $15 more for the Apogee HD than the now discounted Apogee XT Rev 2, just to have the biggest e-peen is a matter for your wallet to decide.

Hey look, ....... over there .... a flock of sheep jetting in a new direction. Interesting random observation.

And to illustrate what I explained above, look at the EK Supreme HF #6 and the Apogee XT Rev 2 when the force applied is 200 N (40 N less than our standard runs).

EK Sup Jet HF #6 / 39. 4 / 39.3 / 39.3

Apogee XT Rev 2 / 39.8 / 39.9 / 39.9

Ahh hah. Dr Watson I believe I see why some people are having conflicting answers in previous waterblock shootouts. Perhaps tomorrow, I will also shed a little more light on how you the reader can use simple math to get a good idea of when a 'reviewer' is falsifying results too. (yes, it does happen)

10:00 AM PST - Here is an illustration of our pressure clamp. I draw faster than I can use Sketch Up.

Midnight PST - Stephen asked for data from the regular OEM mounting equipment that comes with each block.

Here is the average of five mounts (with their mounting hardware) (core avg - water temp), with TX-2 TIM, for the three four blocks:

EK Supreme Jet HF with Plate #6 - Averaged 39.3

Koolance 370 - Averaged 38.9

Swiftech Apogee HD - Averaged 38.5

XSPC Raystorm - Averaged 38.1

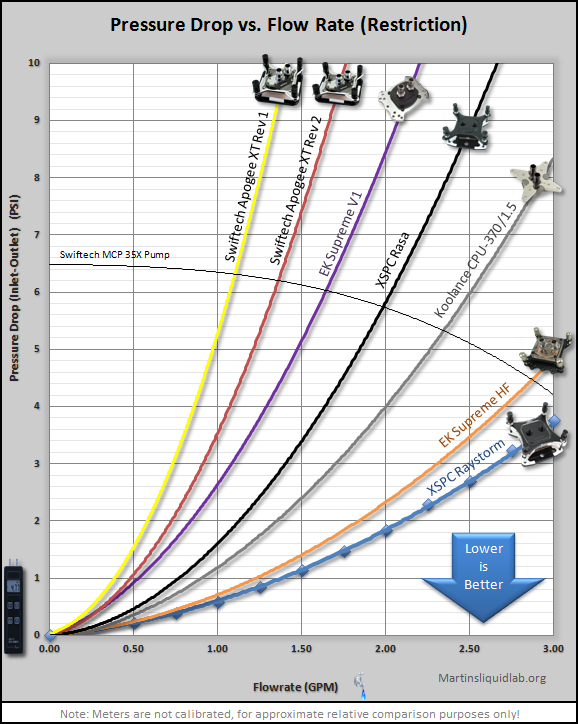

Monday Evening - Sorry folks, had some good swells on Sunday so I got in some surfing. Here is the pressure drop info (restriction) as promised, but first a quick look at what Martinm already found:

I was not able to secure from the organic chemistry division the same exact equipment that Martinm used, but still got to borrow some very nice stuff. For the blocks I tested, my results were very similar to what Martinm found with a few minor differences (but not enough to make a whole new graph), and here are the results of the two blocks Martinm was not able to test in the previous Raystorm review (bc they had not been released yet):

(pressure drop (inlet - outlet) in psi at - 0.5 gpm / 1 gpm / 1.5 gpm / 2 gpm)

EK Supreme Jet HF with plate #6 - 0.2 PSI / 0.68 PSI / 1.3 PSI / 2.13 PSI

Swiftech Apogee HD - 0.86 PSI / 2.7 PSI / 5.65 PSI / 9.9 PSI

So Swiftech did improve the temps while reducing restriction, but I would still call the Apogee HD a medium-high restriction block. It slots in as just slightly more restrictive than the original EK Supreme. Will be great on the new Sandy Bridge 3960X by itself in a cpu loop only but I think I would prefer the Raystorm if I was using the more standard cpu -> possibly chipset block -> gpu loop. It has so much better flow. While I like the Apogee HD, I think after testing these over the weekend, I might prefer the Raystorm. It has a nice repeatable attachment system, the highest flow of any flagship block, the lowest or close to the lowest temps, awesome looks and blue LEDs, and is $15 to $40 cheaper than other flagship blocks. It is pretty hard to beat.

I will check into the multiple port stuff tomorrow or Wednesday if time permits. Quick pressure testing and flow is finished (posted on Sunday morning). Testing the Apogee HD with the new MCR-X20 Rev 3 rads (with coupled MCP 35X pump) with all the inputs and outputs hooked up will depend on if Gabe or Stephen send me a rad for testing. (Using XSPC at home and in the lab these days mainly)

See ya in a bit - Jay

The beauty of the universe can best be understood by learning the language that Mother Nature truly speaks in, ..... mathematics.

(Like math, computer science and figuring stuff out - perhaps you can join us at the UCSD Jacobs School of Engineering)

Reply With Quote

Reply With Quote

.

.

Bookmarks