Hi,

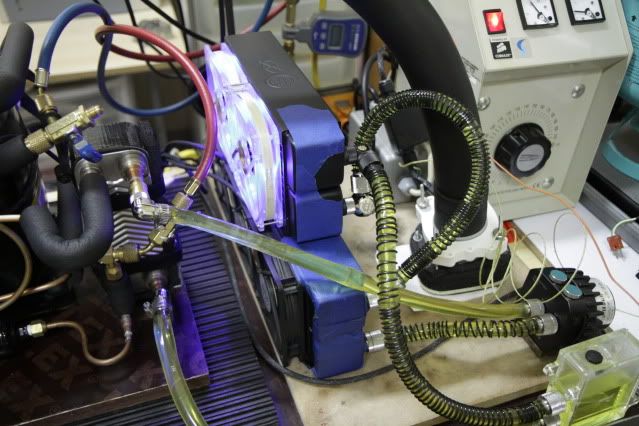

Compressor: Danfoss SC21CL

Captube : 0.036, 245cm

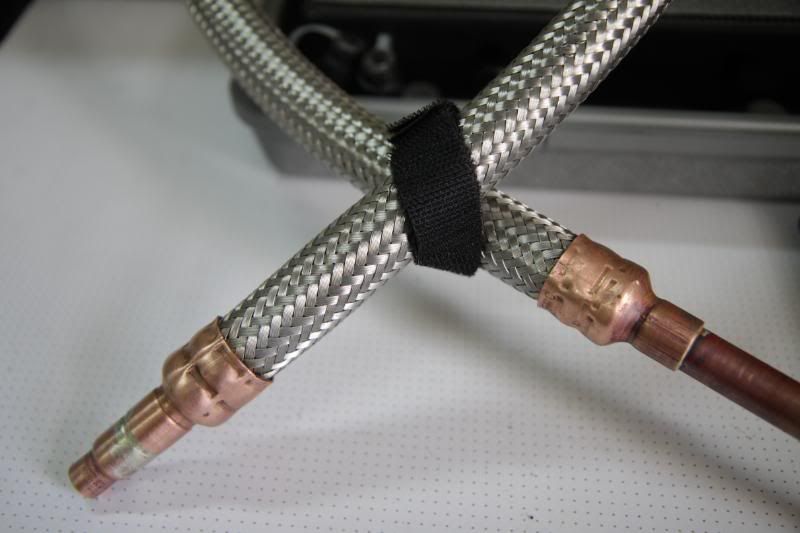

Condensor: plate HX 20 plates

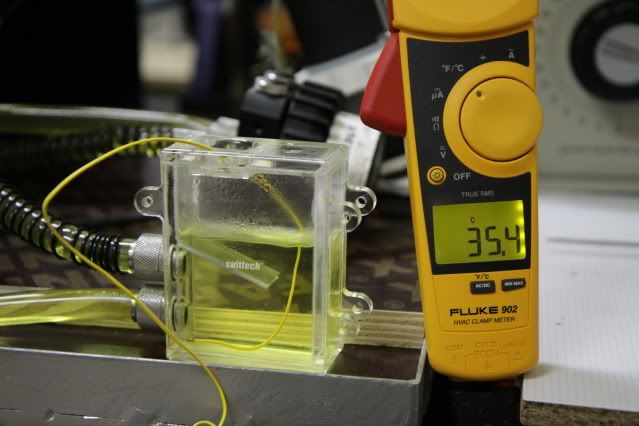

At first I only used the R507, but the cooling performance was not as good!

I then used a mixture R507+Propane The result was as follows ..

UNLOADED

LOADED 250watt,

I could not make the cold stable for more than that!, Because I want 280 watts or more..

What do you advise me? And what do you think is the maximum load can I do with this unit?

Thanks,

Reply With Quote

Reply With Quote

I forgot "you must"

I forgot "you must"

Bookmarks