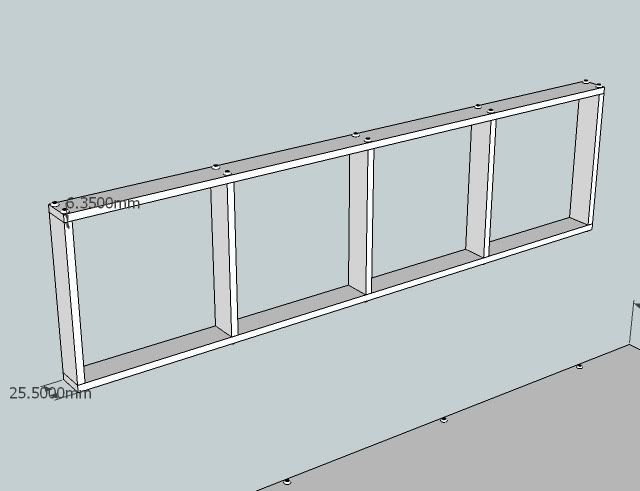

Marts test shows 30mm to be the best, so 30mm thickit is!

Rad is a HW Labs Black Ice GT Xtreme 560(4X140mm)

Fans are Yate Loon SH14-12. I will run 8, push and pull.

I'm confused as to whats the best way to go about getting a 30mm shroud made to fit this thing.

To start with i though about an all in one piece made out of delrin/acetal. This is was to get a nice seal around the rad. To have it machine out as much as the fan mounts on the rad. My confusion then starts from what about where the fans mount, how to do that.

Would it simply be better just to have big round holes machined out the same size as on the Yate Loons?

I'm also no sketch person or have the 1st idea how to go about getting something made.

I'm not after fancy shape, engravings, just quick simple but massively effective to get the absoult best and making it the most 'ard' core setup possible I can.

Any one got ideas, input etc? I could really do with all the help here

Have pulled the specs drawing from there website and attached it here if it helps anyone out.

Reply With Quote

Reply With Quote

uber simple. These going to fit okay on the HW Labs Black Ice GT Xtreme 560(4X140mm) ok? Drawing of measurements is in my 1st post

uber simple. These going to fit okay on the HW Labs Black Ice GT Xtreme 560(4X140mm) ok? Drawing of measurements is in my 1st post

Bookmarks