Just switched tubing, used less (maybe a foot or two?) and its 3/8 instead of the previous 7/16. Temps seem to be exactly the same at load, or possibly a little worse.

The reason this shocks me is because I went from slow Yates mounted directly to the rad to GT AP-15s at the full 1850RPM mounted to a 25mm shroud in push.

The reason I question higher flow is because with bubbles in the res I could see them moving around (can't without bubbles).

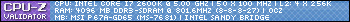

pump: MCP350 with XSPC top

rad: XSPC RX360

Thinking about getting a fan controller for the fans anyway, so would it make sense to hook the pump to it and see if I get improved temps with the pump at a lower speed?

Reply With Quote

Reply With Quote

... has a massive hoard of a Laing DDC pump stash

... has a massive hoard of a Laing DDC pump stash

Yamaha HS80m

Yamaha HS80m

I'm NOT!!! talking about tubes at all!

I'm NOT!!! talking about tubes at all!

Bookmarks