So, I saw some threads here and thought, "I'll have me some of that!"

I have a 12,000 BTU aircon that I no longer use and have commenced dis-assembly...

I was going to try to be clever and put a variable resistor in place of the thermistor to make it think it always needed to run the compressor. Then I decided to just lengthen the wire and stuff the thermistor in the "warm air" exhaust. Problem solved.

Specs:

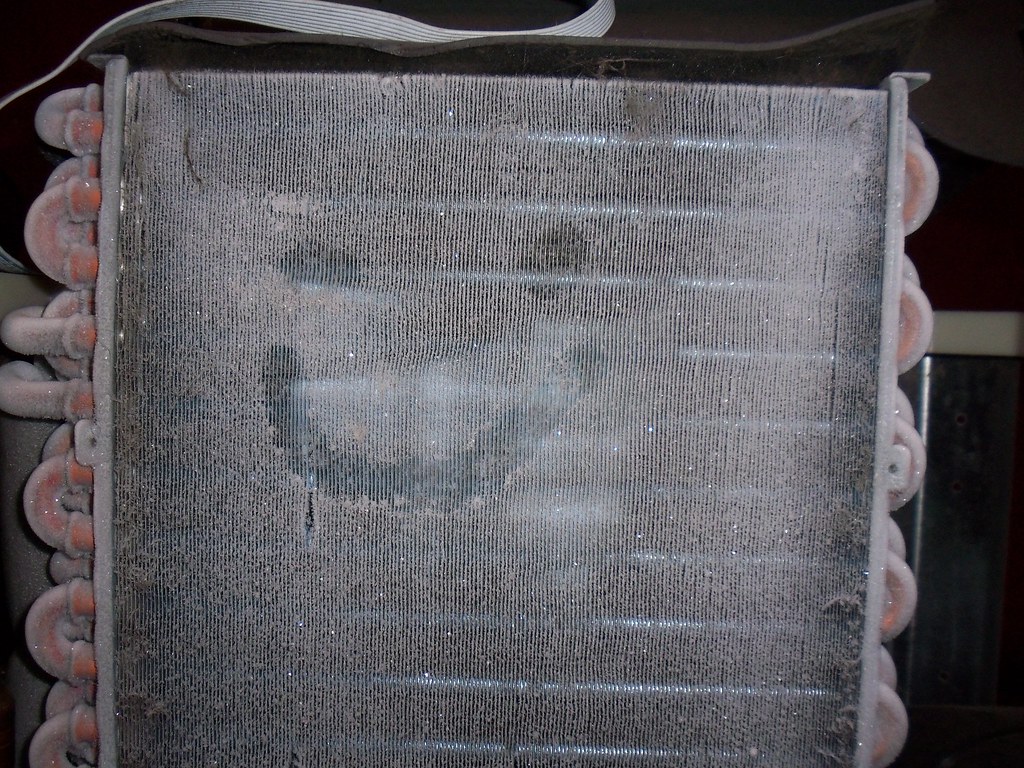

Coldness:

My amazing artistic skills:

More coldness:

I couldn't find a fuse so I used a screwdriver bit for added safety:

Now, I gather from mooching at other threads the theory is to get some sort of coolbox like this: http://www.amazon.co.uk/-/dp/B000TAOVY2?tag=invihand-21

Place this frozen radiator inside it, then fill that with water/ethanol....

For the cooling loop side, do I dump a 360 rad in there as well or do I actually pump that water/ethanol mix around the PC?

If I just pump the water/ethanol mix around, I'm going to have to be careful about algae growth and dust/dirt getting into the coolant, and therefore regularly replace it right?

Is convection and the flow of coolant enough within the coolbox?

The cold side rad is in a kind of awkward position, but is attached by copper pipes, I guess I just have to be very careful not to snap these?

Thanks for any suggestions

Reply With Quote

Reply With Quote

.

.

Bookmarks