Testing turn-around will be about 2 days, need 18 hours of pure test time. Finished with all the fluid I have, thats the reason I am pushing to ship. Yup, same address.

For filling, depends on the loop really. The bench running the coolant tests has an EK150 at the highest point, so I did the fill/pump on-off/fill routine and let the loop bleed for 20 minutes, topped the res off (filled to top threads) to where when I put the cap back on I would usually have a drip or two out the sides, pump off of course. Powered the system on and kicked off the test. Come time for draining, the reservoir level would drop by 5-6mm, never really more than that.

I have 4 bottles in total, but the B1 and C1 had the clumping problem real bad and did not remix entirely when shaken. C2 was the latest one sent over way back when, clumping problem resolved though. Yeah, tube staining isn't really the right word for it... slight coating is better. The coating from C2 did clean up after several flushes.

Loop consists of DDC3.2 with XSPC Top, Swiftech GTZ, DangerDen GTX280's in serial (thanks Conundrum), Koolance FM17 flow meter, Drain T, Temp T1, Temp T2, XSPC RX360 (Yate Lows @ 12v), Temp T3, Temp T4 and an EK 150 Res

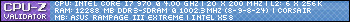

i7 930 @ 3.8GHz (19x200) w/ 1.375v under the GTZ, 280's are at stock clocks with 1138mV and some UV (little things are bright) provided by the Gigabyte UD7. OCCT loads the CPU and Kombustor on all threads for the GPU's.

Testing turn-around will be about 2 days, need 18 hours of pure test time. Finished with all the fluid I have, thats the reason I am pushing to ship. Yup, same address.

Reply With Quote

Reply With Quote

Bookmarks