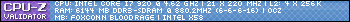

CPU: Core2Quad q6600 G0 3.5GHz@1.4v (highest so far 4.2GHz)

GPU: XFX 9800GTX @ 850/1230

Ram: Samsung 4GB (4x1GB) 700MHz PC5300

Mobo: EVGA-NF68-A1 680i (P32)

PSU: Enermax Galaxy 850Watt DxX

HDD:WD5001AALS, ST3250410AS, ST3500410AS, ST3500320AS - 1.75TB

DVD: LG H26N,LG GH20LS10 both sata

LCD: Samsung 32" LN32A450, Samsung 226BW 22" wide

Sound: Logtiech Z 5500/Razor Barracuda HP-1 / AC-1

CPU & GPU: 3x Swiftech MCR320, 2x MCP655, MCW60 R2, Dtek Fuzion V2, 18 high speed yates @ 5v

3Dmark06:17,814 AquaMark:190,865

Reply With Quote

Reply With Quote

I call it a acrylap

I call it a acrylap

Bookmarks