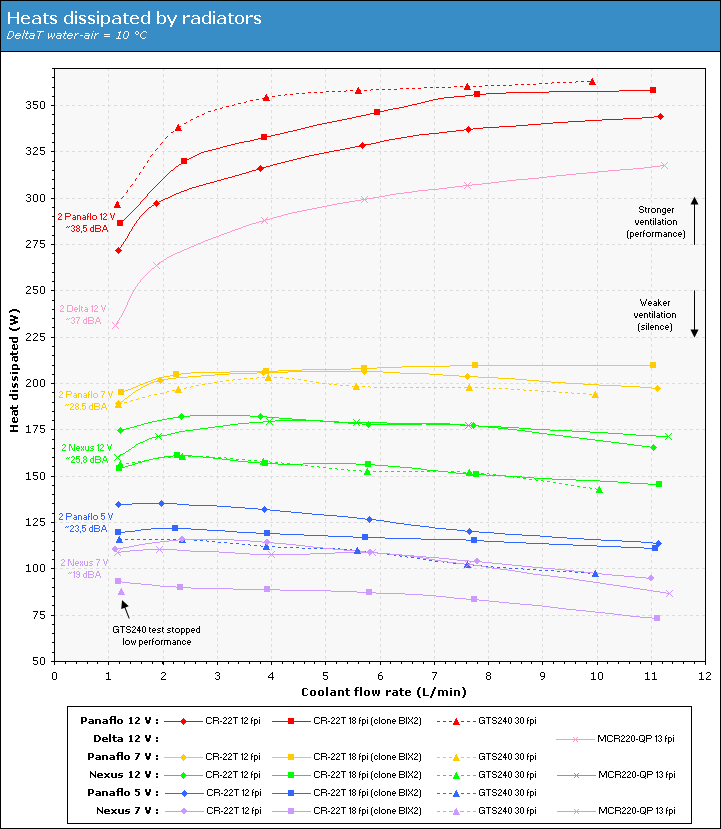

Been playing around with some flow specific radiator testing and getting wierd results. After referring to other tests, I noticed the old coolingmasters review measured something similar. On their review they measured that with lower RPM fans, many of the rads begain showing worse performance with higher flow rates:

Any theories as to why?

Reply With Quote

Reply With Quote

*

*

Bookmarks