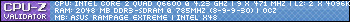

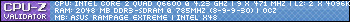

Asus Rampage Extreme W/C NB/SB

c2q6600 @ 4239mhz @ 1.69

2GB Ocz Flex II DDR3-2000 8-9-9-28

Asus 3870X2TOPs' quad xfired

2x WD 160gb raid0

1x WD 80gb backup

Sony optical drive

Samsung optical drive

VapoChill LS Jin Mod'd

Aqua Computer 360XT Water Tower

Via Aqua 50c 1/3Hp Water Chiller

EnzoTech north, south and mosfet blocks

Danger Den Maze-5 vga blocks x4 for 4x-xfire

Hp 2408H 24'' lcd

View Sonic 22'' lcd

2x custom plexiglass cases 1-PC & 1-LS

Apevia 680w psu & Logisys 550w psu

Logitech Di Novo Edge Keyboard

Optimus Mini 3 Keyboard

Saitek Obsidian mouse

3D Connexion Space Pilot 3D mouse

Upek Fingerprint reader

Plantronic 590 Bluetooth headset

HP 7550 Photo Printer

HP 4670 See-Thru Scanner

NextEngine 3D Scanner

//UPGRADES COMING SOON//

i7 965,Rampage II Extreme, Koolance liquid-cooled psu, and a new _itch to blow me while I type(jk on the last one...hmm...2nd thought...it be nice)~!!!

http://valid.canardpc.com/show_oc.php?id=507958

http://www.techpowerup.com/gpuz/g8qs9/

http://valid.canardpc.com/show_oc.php?id=507958

http://www.techpowerup.com/gpuz/g8qs9/

Reply With Quote

Reply With Quote

I'll be testing grain alcohol + dry ice later tonight I think, picking up some dry ice to finish off the Koolance CPU-LN2 review, might as well combine it with this project.

I'll be testing grain alcohol + dry ice later tonight I think, picking up some dry ice to finish off the Koolance CPU-LN2 review, might as well combine it with this project.

Bookmarks