This air cooled TEC module is designed to directly cool a wolfdale E8400 on a DFI UT P35 T2R board.

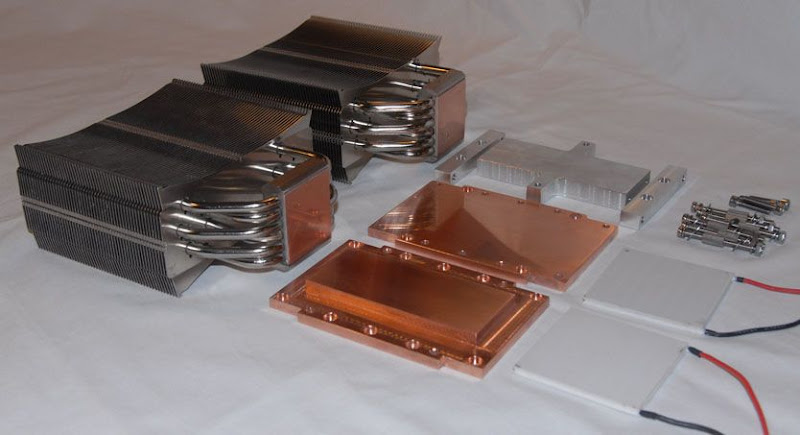

The parts. The TECs are of the 62mm variety available on ebay

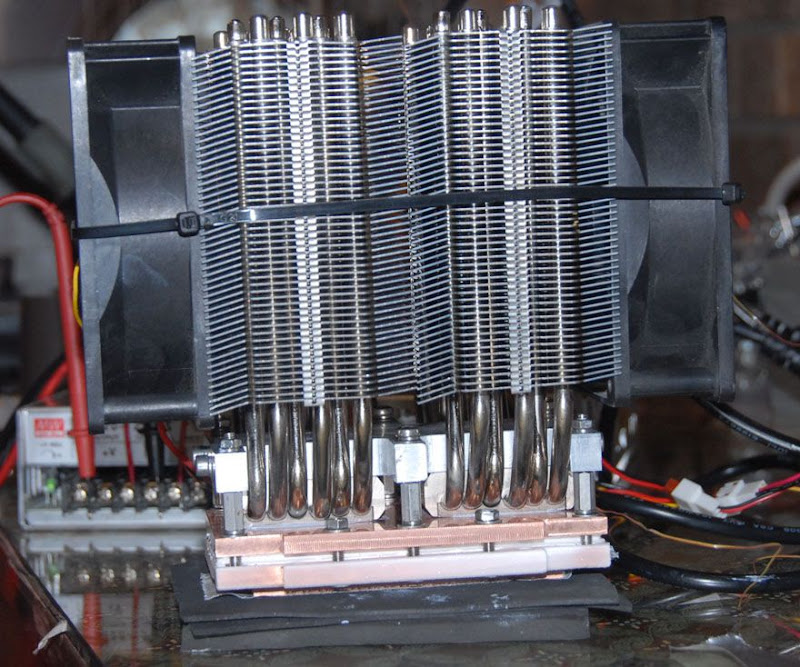

assembled profile view

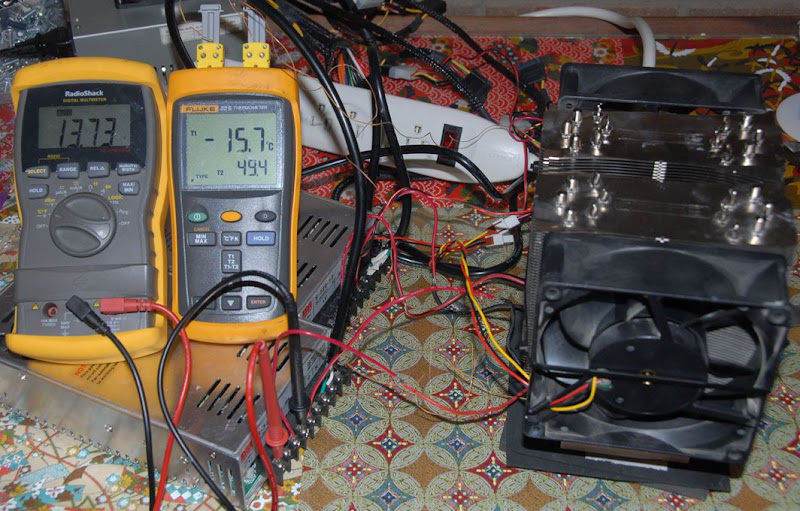

Power Supply Voltage= 13.73V

Temperature hot plate = 49.4C

Temperature cold plate = -15.7C

Power Supply Voltage= 9.2V

Temperature hot plate = 33.8C

Temperature cold plate = -18.0C

more pics to come....

Reply With Quote

Reply With Quote

Just the heat from the TEC's themselves. Lower voltage with no load giving you better temps means your hot sides too hot. And 50C is too hot.

Just the heat from the TEC's themselves. Lower voltage with no load giving you better temps means your hot sides too hot. And 50C is too hot.

gl

gl

Bookmarks