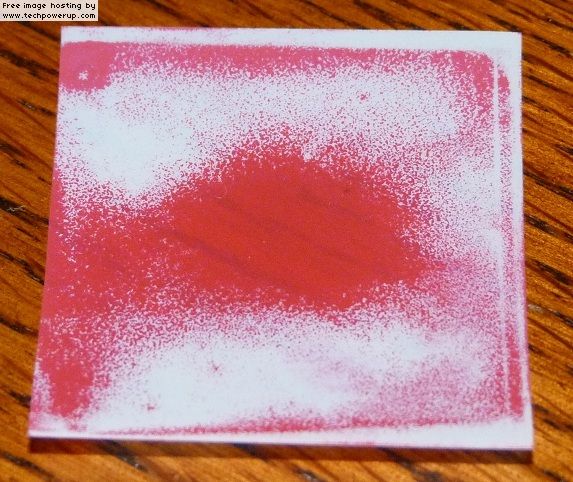

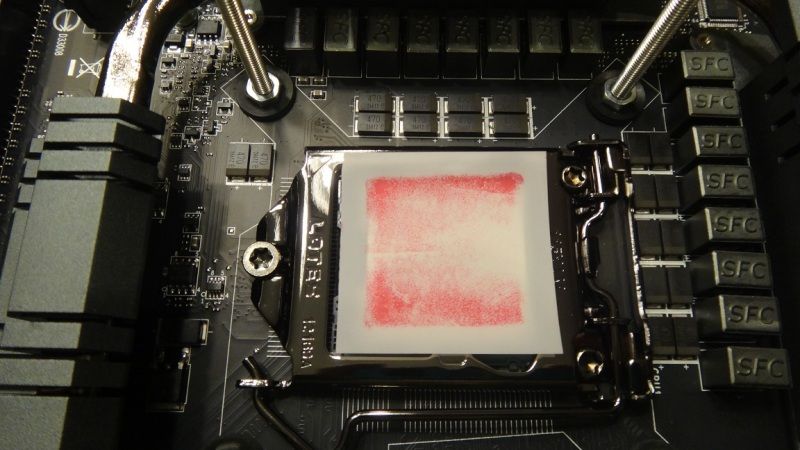

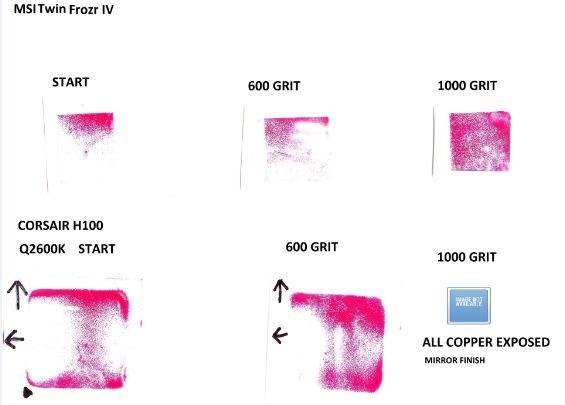

Key thing to remember - increased contact does not increase pressure, but generally increased pressure will increase contact. Pressure is the more dominant of the two.

Let's flip the problem, In engineering a common device used to limit heat flow to sensitive components in an assembly is a ?Heat Dam? shown here in figure #3 Where the heat flow is ?thermally choked? by reducing the contact area to material limitations. Restricted heat flows with misaligned contact, too little contact, too little pressure, too little compound anything that can restrict flow creates a heat dam.

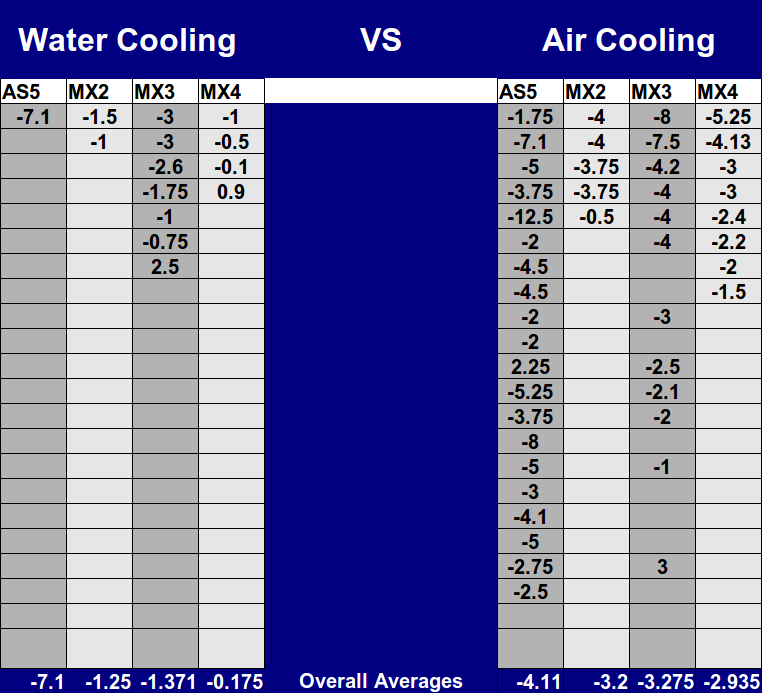

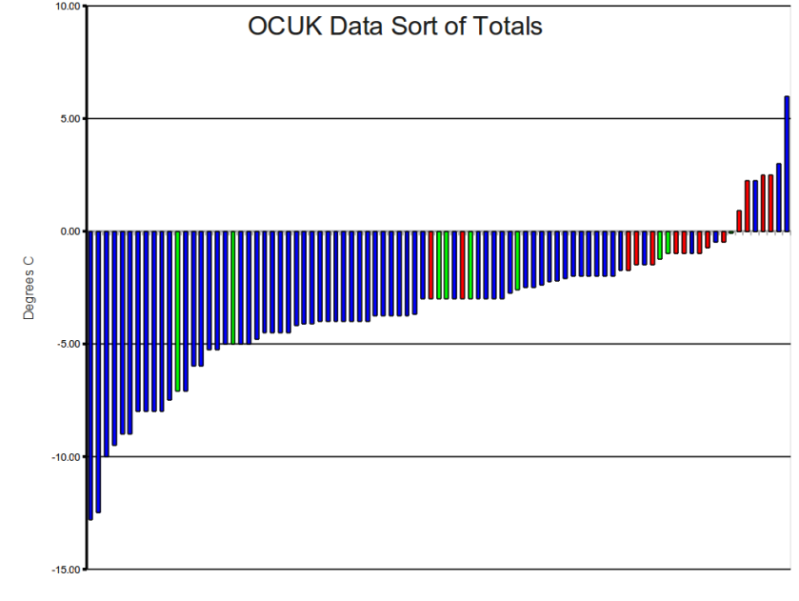

Heat flows on a differential from hot to cold but if you are thermally choked at a point in the thermal cascade downstream improvements in thermal conductivity offers little difference in performance and shows up as reduced deltas of only a degree or so between compounds or what I sometimes refer to as homogenized test results. So water blocks or just poor contact in general is a poor vehicle for comparison testing thermal compound.

These are the thresholds or tipping points and all your ducks need to lined up in detail to squeeze the most out of your systems.

Reply With Quote

Reply With Quote

you maay be showing your age if you have experience of old engines like that

you maay be showing your age if you have experience of old engines like that

Just noticed, I must be old my memory runs into the decades

Just noticed, I must be old my memory runs into the decades

Bookmarks