Polishing doesn't soften metal. Could you post a picture of what happened or have you already lapped it out?

Polishing doesn't soften metal. Could you post a picture of what happened or have you already lapped it out?

[SIGPIC][/SIGPIC]

i see 2 IC Diamond at petratech- the 7 and 24 carat, does it matter?

Main rig:

CPU: I7 920C0 @ 3.6Ghz (180*20)

Mobo: DFI UT X58 T3eH8

RAM: 12GB OCZ DDR3-1600 Platinum

GPU/LCD: GeForce GTX280 + GeForce 8600GTS (Quad LCDs)

Intel X25-M G2 80GB, 12TB storage

PSU/Case: Corsair AX850, Silverstone TJ07

So this is the best thermal paste to use right now? No longer Artic Ceramique or AS5?

*CPU: Xeon X5650 @ 4.3 Ghz | Cooler: Thermaltake Water 2.0 Extreme

*Asus Rampage III Formula | RAM: 36GB DDR3 (Tracer LED + Hyper X Savage)

*Video Cards: Gigabyte Aorus 1080ti

Sound Card: Sound Blaster Z | PSU: Corsair HX1000W | Display: BenQ PD3200u | JVC RS520 projector

*Case: CoolerMaster HAF X (932 side panel) | Others: Roccat Kone AIMO | Roccat Alumic | Logitech G15 |Cameras: Sony A7R3 | RX100 V

shaolin95 I stopped buying ceramique and as5 a year ago.

This stuff works a lot better IMO

shaolin95, I'll confirm what littleowl is saying, best stuff I've used.

Wesley

+3 here. It's the only stuff I use now. I get reliable mounts that last a very long time....

Bob

EDIT: looking at the date of my first post on this thread, I have some mounts that are about to turn 1 year old.

I have a small giveaway going with some laptop guys that adds a little different viewpoint to application potentials for those that have an interest.

Laptops

Also lost this post for reference so reposting

Some edits coming over the next couple of days on the following report

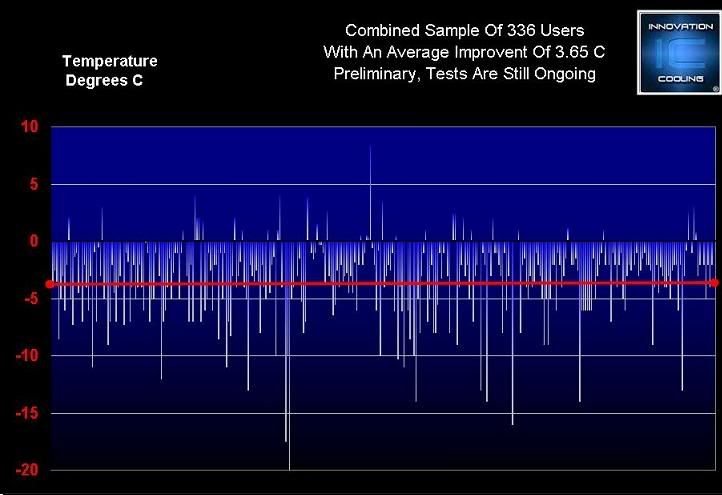

I am starting a compilation of all forum test data that has been acquired from the forum giveaways to date. Some compounds are used so rarely it is impossible to break them out of the pack. In any event with the number that that has added up to date I can start to combine results with the other giveaways and break those out of the pack and will add those chart comparisons also.

More credence should be given to larger sample sizes, smaller less so.

1-5 samples 1 or two tests can flip results either way so usually get thrown onto the miscellaneous group.

6-10 samples may start to indicate trends but can be heavily influenced by outliers and so are lightly weighted other than a general trend indicator

11-20 samples - Starting to develop more of a confidence in the trend direction.

20-30 samples - Confidence level improves to around 95% at this point.

Some edits coming over the next couple of days-

What is different in this final report is I am combining results from all forums to date (with the exception of AMDZONE they reworked their site and deleted the thread before I had a chance to copy all data) and breaking out some of the individual compounds.

These are of course preliminary and more of a snapshot as data is being added every day and so is subject to revisions, changes and corrections as needed. All data are independent user results and IC treatment is limited to Averaging and plotting the charts. All data is publicly available for review at Overclockers.com,Overclock.net, Overclockers Austraila, Anandtech, xtremesystms, HardewareLogic and HardwareCanucks.

First up is the generic white compounds and unidentified pastes that shipped with the installed sink.

Generic white or stock paste- 26 users 7 forums

Next AS5 -125 users from 7 forums

Next MX2 - 36 users from 7 forums

Next OCZ Freeze -11 User results from 7 forums

Next TX-2 -3 User results from 7 forums, 3 results from review sites

Next ShinEtsuX23 -7 User results from 7 forums, 3 results from review sites

Next Ceramique -9 User results from 7 forums

Next Thermalright -6 User results from 7 forums

Next Misc -11 User results from 7 forums

Preliminary, some edits, corrections to be added Later

Last edited by tastymannatees; 05-03-2009 at 10:40 AM.

I harp on reliability on all the forums but mostly I am ignored on the subject. For those that focus only on temps take a look what can happen in just a month.

The more liquid type pastes have more of a tendency to pump out or bake out. Though they wet well and give good performance out of the gate, if stressed you can run into this problem

Another Review For those that have an interest

Just ordered a tube today from Frozen CPU. Guess I made the right choice. Just hoping I don't get addicted to the "stuff."

I am updating all forum results to date for the website 10 forums 336 user tests.

I thought you might be interested in our progress as you guys were one of the first to test IC Diamond

Thanks for the update! Nice results.

wow i never knew some one was working his butt off on this thing

nice man rather awesome stuff there

[i7 920 @ 4.48Ghz TRU 120+MX3 || ASUS P6T || CHAINTECH 2x2GB 1800mhz 6-7-8-22 || SPARKLE 460GTX 1GB 905/1065/1810||SGATE 1TB+640GB||CORSAIR TX 750|| VX 2433 || CM 690 || NZXT FANCONTROLER ]

i7 920 @ 4.48Ghz+Tru120+Asus P6T

I7 920 @ 3.9Ghz+stock+Intel DX58SO

Q9550 @4Ghz (445x9)+Tru120+Giga p45

Q6600@4Ghz (445x9)+Tru 120+Giga Ga p35ds3r n Asus Maximus 2

E5200@4.2Ghz+Tru 120+Ga p35ds3r

E6750@3.95Ghz+asus ss pro+Asus p5Kvm

E4500@3.63Ghz+Asus SS+spro+Asus p5kvm

Join me on Pakistan's First Overclocking Forum

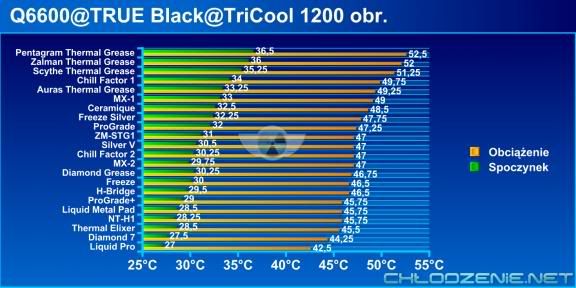

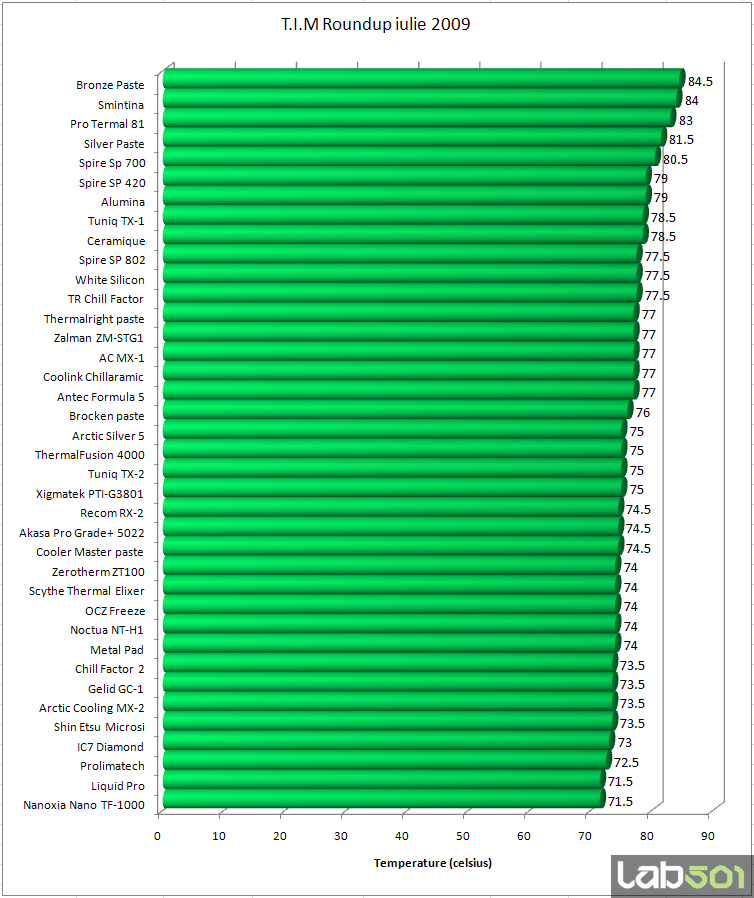

Thermal paste roundup @ lab501.ro

Q6600@ 3.5Ghz / 1.4V

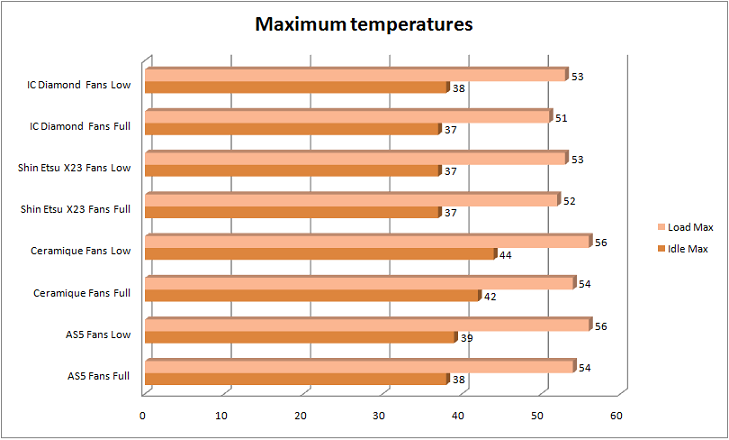

Thanks I have not seen that one. What is interesting to me is the ones with the more exotic materials; liquid metals, Diamond consistently place at the top end and probably portends what's in for the future.

Single tests are tough to draw conclusions on while I am sure each reviewer takes care hierarchical flips are common between reviewers. Take the Scythe Thermal Elixer , OCZ and Prolimatech and I have IC Diamond on a couple of charts doing the same with liquidpro on my website (just scroll down. Review samples gets large enough I'll average that out too although it's taken me 2 years to get roughly 10 and compounds are being obsoleted faster than the review cycle,

That why I prefer the forum tests as I get the data from Independent users in a sample size that filters out a lot of the anecdotal results.

http://baltichw.com/naujiena/n/a/the...art_three.htmlIC Sampling Vs. Individual Tests

Single tests generated by review site, individual or even IC are anecdotal in nature subject to limitations of methodology. While most pursue the most rigorous test procedure possible they still encounter fluctuations of several degrees C between reviews.

Why does every review come to a different conclusion? The problem is that their sample size = 1.

Even collecting multiple readings the cluster size is = 1. An individual can collect all the data readings off one system, and will still have almost no statistical power (In statistics this is known as "Intra-Sample Cluster Correlation")because the test set up is dominated by methodology. This is a problem not only in paste reviews, but in other hardware reviews, heat sinks, etc. as well.

In the final analysis methodology ends up defining the final placement of all compounds- All test methodologies fail to take into account things that have a major impact on paste performance. For example the mounting system along with mechanical contact between IHS and sink as evidenced with our independent contact/pressure testing. Variability was very high on the contact results with perhaps 1 in 10 having any thing near what you might call full contact, even on those with lapped components.

In considering pressure related to mounting hardware some pastes perform relatively better under poor mounting, others perform relatively better under good mounting (viscous ones such as ICD). Considering ICD - people that had poor results with ICD had very poor mounting. Once they improved that mounting, ICD did considerably better. Of course, so did their old paste. But ICD improvement >> old paste improvement. Generally, this resulted in ICD>old.

The debates that any one review is the final word are of little substance. However multiple reviews serve an important function along with observations of user experiences allow individual users to either consciously or unconsciously mentally benchmark results.

In summary, sample size = 1 tells little. . Sample size matters!

ICD has been extensively tested by 391 independent users in 11 forum groups data that is compiled with real world, real users test results

Last edited by tastymannatees; 08-24-2009 at 09:09 AM.

I'm thrown a bit off by this statement. We want as little goop in between the surfaces as possible. If the excess slowly creeps out, why is that a bad thing? We'll just be left with an ever-thinner layer until all there is are the two surfaces and a minimum compliment of thermally conductive filler.

Particle's First Rule of Online Technical Discussion:

As a thread about any computer related subject has its length approach infinity, the likelihood and inevitability of a poorly constructed AMD vs. Intel fight also exponentially increases.

Rule 1A:

Likewise, the frequency of a car pseudoanalogy to explain a technical concept increases with thread length. This will make many people chuckle, as computer people are rarely knowledgeable about vehicular mechanics.

Rule 2:

When confronted with a post that is contrary to what a poster likes, believes, or most often wants to be correct, the poster will pick out only minor details that are largely irrelevant in an attempt to shut out the conflicting idea. The core of the post will be left alone since it isn't easy to contradict what the person is actually saying.

Rule 2A:

When a poster cannot properly refute a post they do not like (as described above), the poster will most likely invent fictitious counter-points and/or begin to attack the other's credibility in feeble ways that are dramatic but irrelevant. Do not underestimate this tactic, as in the online world this will sway many observers. Do not forget: Correctness is decided only by what is said last, the most loudly, or with greatest repetition.

Rule 3:

When it comes to computer news, 70% of Internet rumors are outright fabricated, 20% are inaccurate enough to simply be discarded, and about 10% are based in reality. Grains of salt--become familiar with them.

Remember: When debating online, everyone else is ALWAYS wrong if they do not agree with you!

Random Tip o' the Whatever

You just can't win. If your product offers feature A instead of B, people will moan how A is stupid and it didn't offer B. If your product offers B instead of A, they'll likewise complain and rant about how anyone's retarded cousin could figure out A is what the market wants.

This is a well understood problem with lots of documentation, papers. reports articles etc. Thermal expansion and contraction "pumps" the liquid out of the joint - You are right to a point but the pump system goes beyond the point you describe leaving voids, air gaps that cause compound failure.

The curing or settling in process that many observe with their temps improving a couple of degrees some period of time after installation is the compound resolving down to the average particle size generally in a couple of hours or days depending on the pressure, heat.

Most OEM's recommend bulk loading's above 90% for the simple reason that the more solid a compound is, the harder it is pump out. It is hard to make a compound with high bulk loadings (reliable) and great performance. The hyper competitive retail compound market has many 'thin" type pastes that provide good performance out of the gate but "fail" in just a couple hundred hours. So much for instant gratification

An example here for you

IC Diamond initially settles to bond line thickness Then hardens a bit over a couple of weeks becoming kind of crayon like in consistency, still pliable it is too thick at this point to be pumped out. This was by design on our part for extended reliability.

I am now about roughly 3 years on an office system with no change in temp from the initial install.

Last edited by tastymannatees; 08-11-2009 at 12:30 PM.

Latest update

NOTE ON COMPARISONS

When comparing results more credence should be given to larger sample sizes, smaller less so.

1-5 samples 1 or two tests can flip results either way so usually get thrown onto the miscellaneous group.

6-10 samples may start to indicate trends but can be heavily influenced by outliers and so are lightly weighted other than a general trend indicator

11-20 samples - Starting to develop more of a confidence in the trend direction.

20-30 samples - Confidence level improves.

30+ Samples - High degree of confidence

The laptop tests are from Notebook Review and help illustrate the expanded range of IC Diamonds use in in different applications. The VC/GPU tests across multiple forums I am in the process of breaking out and including those done here will be added as a final chart here at some point. The higher delta temps is due to no IHS and a smaller die contact, providing higher heat fluxes, hence the higher temp differences along with other factors such as compound failure due to the high thermal loads

Bell Curve Notes

About half the data is reported in round numbers and approximately 50% of the total numbers were fractional numbers, so to include all numbers in the set I rounded the fractional numbers to the nearest ½ degree. This had a minimum impact on the overall numbers, for instance the mean dropped less than 2/100ths of a degree.

Notes: IC Sampling Vs. Individual Tests

Innovation Cooling elected to use this more or less unique method to introduce our products as the review cycle runs like molasses for thermal compounds, 10 -12 for ICD in the last 2 years with many comparisons already obsoleted due to new product cycles.

Hardware reviews serve an important function along with observations of user experiences allow individual users to either consciously or unconsciously mentally benchmark results. Our problem was there were not enough reviews to to make comparisons on as compound comparisons are notoriously tedious vs. heat sink or other hardware.

Single tests , individual or even those done by Innovation Cooling are anecdotal in nature subject to limitations of methodology. While most pursue the most rigorous test procedure possible they still encounter fluctuations of several degrees C between tests/reviews.

Why does every test come to a different conclusion? The problem is that their sample size = 1.

In the final analysis methodology ends up defining the final placement of all compounds- All test methodologies fail to take into account things that have a major impact on paste performance. For example the mounting system along with mechanical contact between IHS and sink as evidenced with our independent contact/pressure testing. Variability was very high on the contact results with perhaps 1 in 10 having any thing near what you might call full contact, even on those with lapped components.Even collecting multiple readings the cluster size is = 1. An individual can collect all the data readings off one system, and will still have almost no statistical power (In statistics this is known as "Intra-Sample Cluster Correlation")because the test set up is dominated by methodology. This is a problem not only in paste reviews, but in other hardware reviews, heat sinks, etc. as well.

In considering pressure related to mounting hardware some pastes perform relatively better under poor mounting, others perform relatively better under good mounting (viscous ones such as ICD). Considering ICD - people that had poor results with ICD had very poor mounting. Once they improved that mounting, ICD did considerably better. Of course, so did their old paste. But ICD improvement >> old paste improvement. Generally, this resulted in ICD>old.

In summary, sample size = 1 tells little. . Sample size matters!

ICD has been extensively tested by 391 independent users in 11 forum groups data that is compiled with real world, real users test results

Another review for the "mental" averagers

Here's my review I posted a couple weeks ago:

Main Review: http://vapor.skinneelabs.com/TIM/IndigoX/IndigoX.html

MX-3 and Ceramique added: http://vapor.skinneelabs.com/TIM/IXS...nt/IXSupp.html

Nice charts, looks like a pressure or contact issue from the data.

Why does every test come to a different conclusion? The problem is that their sample size = 1.

Even collecting multiple readings the cluster size is = 1. An individual can collect all the data readings off one system, and will still have almost no statistical power (In statistics this is known as "Intra-Sample Cluster Correlation")because the test set up is dominated by methodology. This is a problem not only in paste reviews, but in other hardware reviews, heat sinks, etc. as well.

In the final analysis methodology ends up defining the final placement of all compounds- All test methodologies fail to take into account things that have a major impact on paste performance. For example the mounting system along with mechanical contact between IHS and sink as evidenced with our independent contact/pressure testing. Variability was very high on the contact results with perhaps 1 in 10 having any thing near what you might call full contact, even on those with lapped components.

In considering pressure related to mounting hardware some pastes perform relatively better under poor mounting, others perform relatively better under good mounting (viscous ones such as ICD). Considering ICD - people that had poor results with ICD had very poor mounting. Once they improved that mounting, ICD did considerably better. Of course, so did their old paste. But ICD improvement >> old paste improvement. Generally, this resulted in ICD>old.

In summary, sample size = 1 tells little. . Sample size matters!

80% see a positive result out of the gate ICD. 16 % that did not were determined based on our sampling were determined to have insufficient contact or Pressure. So from our data we can account for 96% of users results.

A single test is anecdotal, even my own with $100,000 in thermal test equipment at my disposal is still a sample of one.

Testing is always relative, you can compare thermal compounds one on one which is commonly done or you can test against absolute limits for a reference point. I thought this might be another interesting viewpoint for some.

Notes On The Limits Of Thermal Grease Performance

The best possible performance for any thermal grease would be 100% heat transfer from the CPU to the heatsink which is impossible. We have measured thermal performance for the best possible case directly soldering the CPU to the heatsink. In this extreme case using a solder joint, the difference between the CPU and the heatsink was 0.5 degrees C.

Based on test results from 391 users among 11 PC Forums and IC tests, IC Diamond Thermal Compound showed 0.8 0.9 C difference between the CPU and heatsink a difference of only 0.4 C compared to the solder joint.

User results showed other thermal compounds ranging from 1.1 C to 4.7 C difference less performance than IC Diamond, as shown on the performance graph, a difference due to the ingredients in the thermal compound used. Twenty years of thermal compound development have reduced the difference between using a solder joint to about 0.4 C. Further development may reduce this difference by a few tenths of a degree.

In our final market analysis before we launched ICD to market, IC tested the most competitive retail compounds and performed the solder test. These tests gave us the confidence to incorporate the giveaway's for forum testing/market introduction as we were confident ICD would transition well into real world user testing and that at best a competitor may match our performance but will never definitively outperform ICD. IC Diamond and has since been proved out so far with 400+ independent tests on 11 forums with experienced users nationally, internationally in a comprehensive sampling of hardware, software and environmental conditions.

Bookmarks