Possible crude mounting test would be first test horizontal then rotate the board to vertical and see if your temps change. Heat pipe performance might be affected although water and stock type sinks I think would be OK.

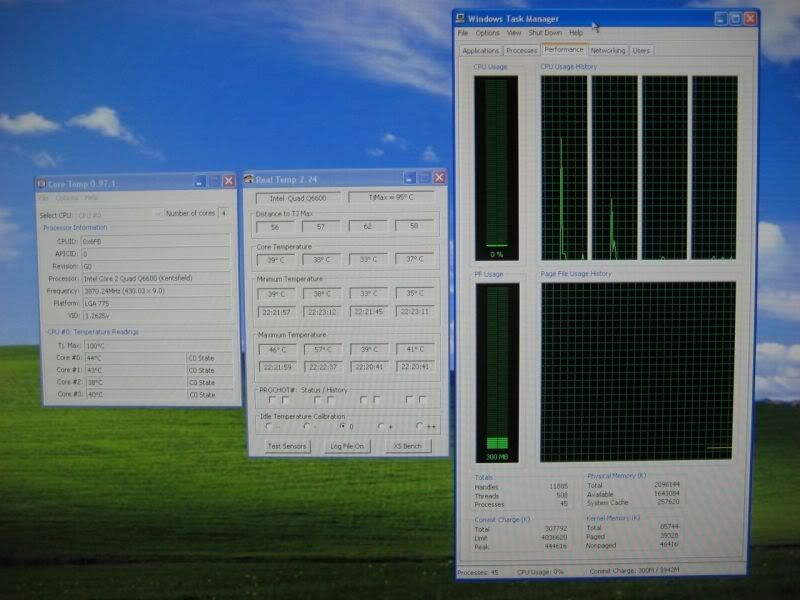

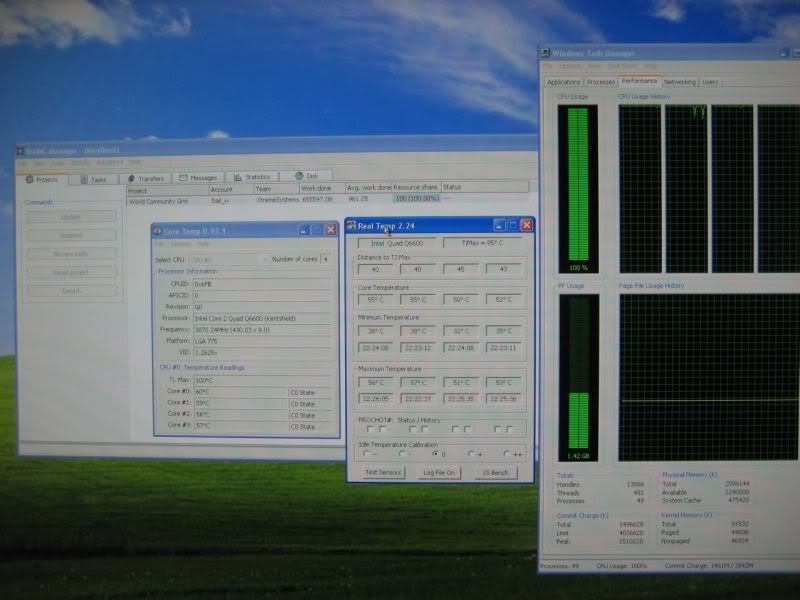

What's awkward about this kind of testing is the minutia that emerges when trying to parse the last couple of degrees.

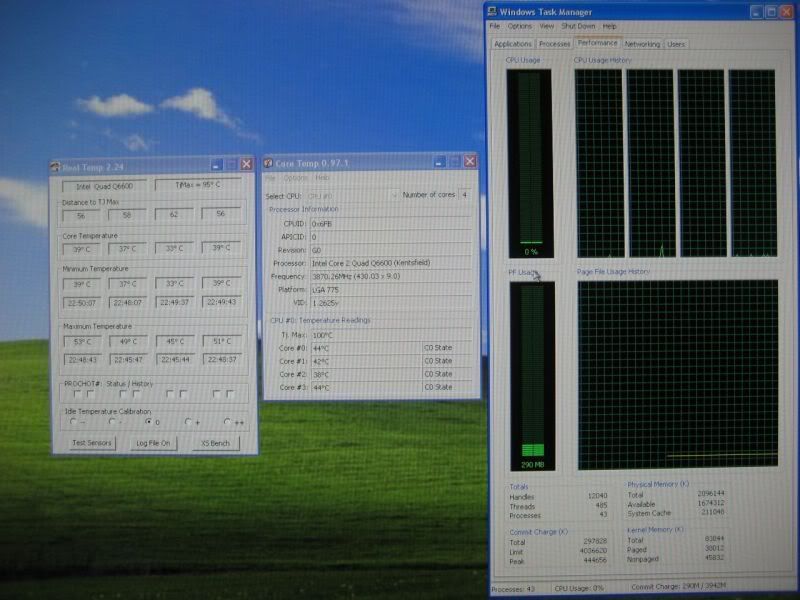

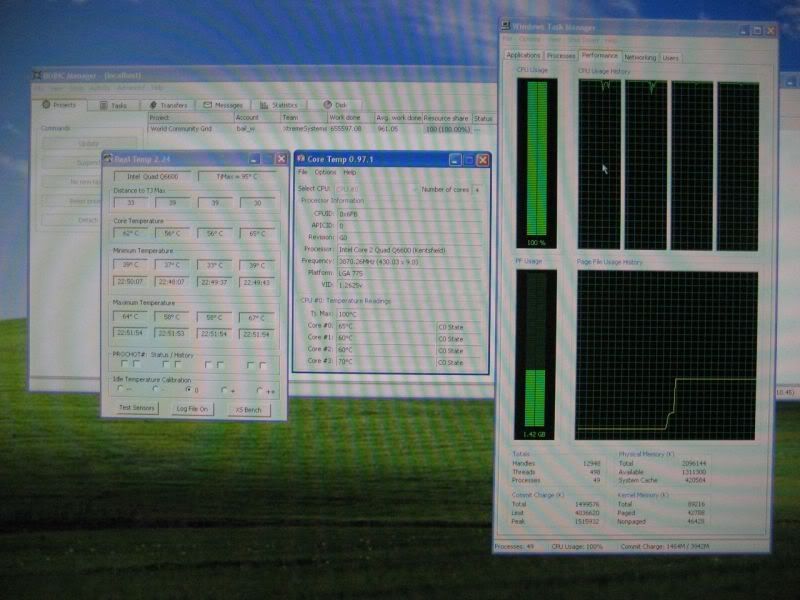

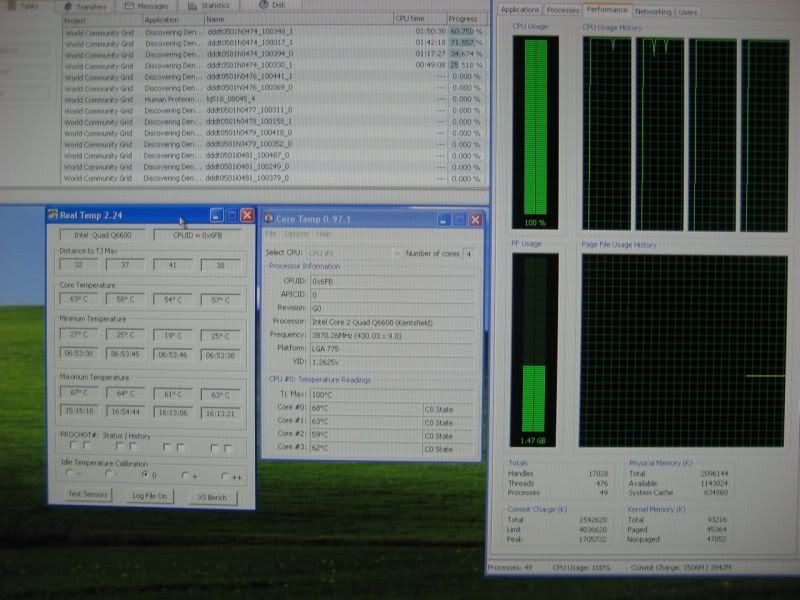

On OC tests the average of 45 or so ended up to be 2.8-2.9 C - Subjectively a well motivated group

Hardwarelogic with the emphasis (I assume) on the "pea" averages increased to 3.7-3.8C - A highly motivated group

Anandtech is in process with "pea" emphasis with only 8 people reporting so far ( I like 20+ for the averaging) is at 2.5C. - Highly motivated group, one user was experimenting spreading the paste with a vibrator

AmdZone which is just about finished come in at around 2.3 C with low enthusiasm, low response rate - Most on those that signed on for a free sample it was their first and sometimes their last post on the forum which is why my focus changed to the more stable, experienced dedicated Distributed computing forums.

You have to assume that different "island" community forums will have some different mixes of before compounds and equipment That will move the averages a couple of 10th's of a degree one way or another.

I would like to get the averages up a bit overall, which should be doable.The devil is the detail.

The break in or cure time I do not have nailed and I would like to be able to say something like "2 hours to 2 days depending on sink pressure" or whatever it works out to be. so some attention here would be appreciated. Thanks everybody

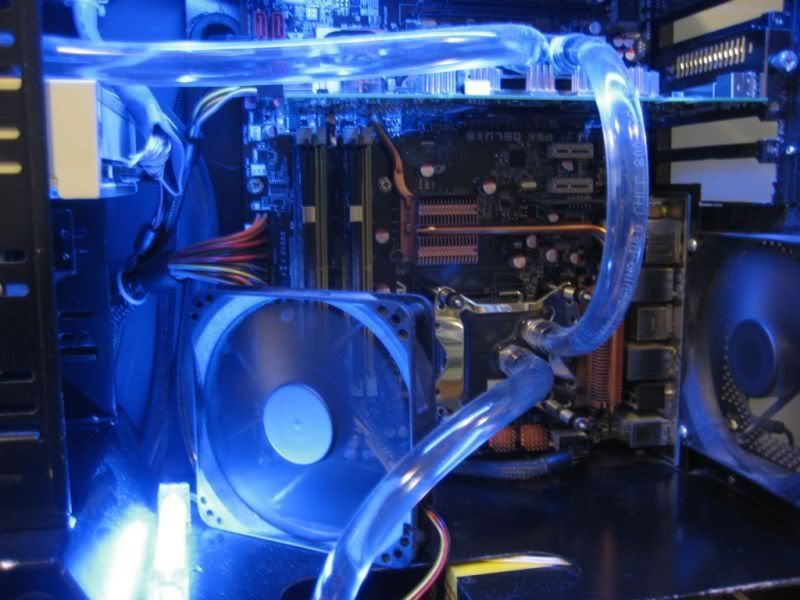

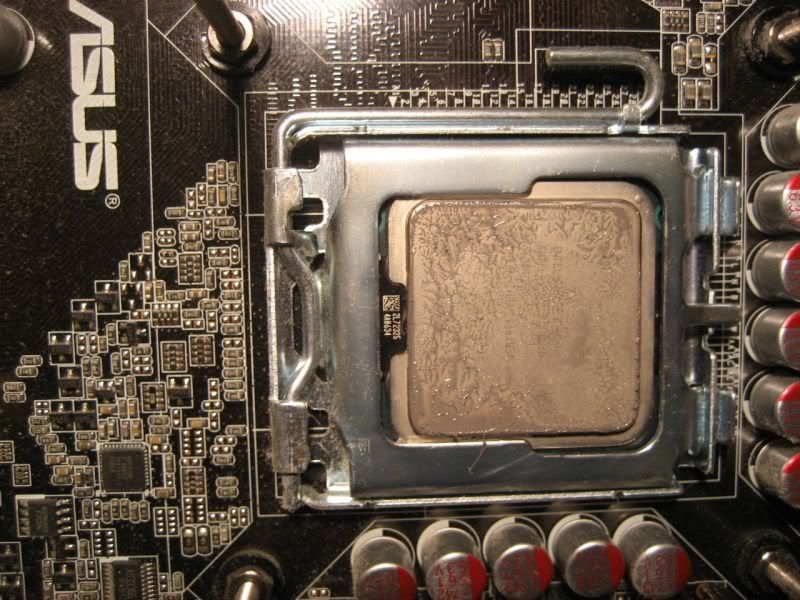

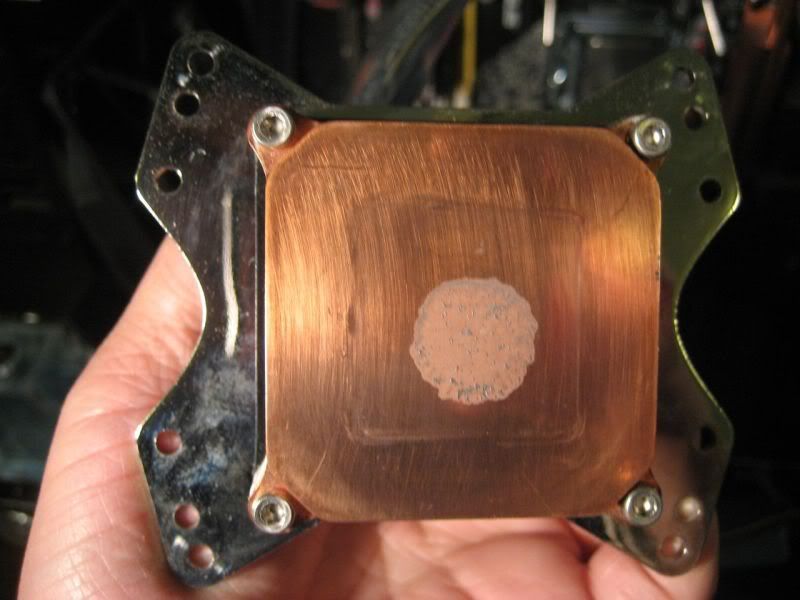

my wife's system now!

my wife's system now!  I Feel really Good now!

I Feel really Good now!

Reply With Quote

Reply With Quote

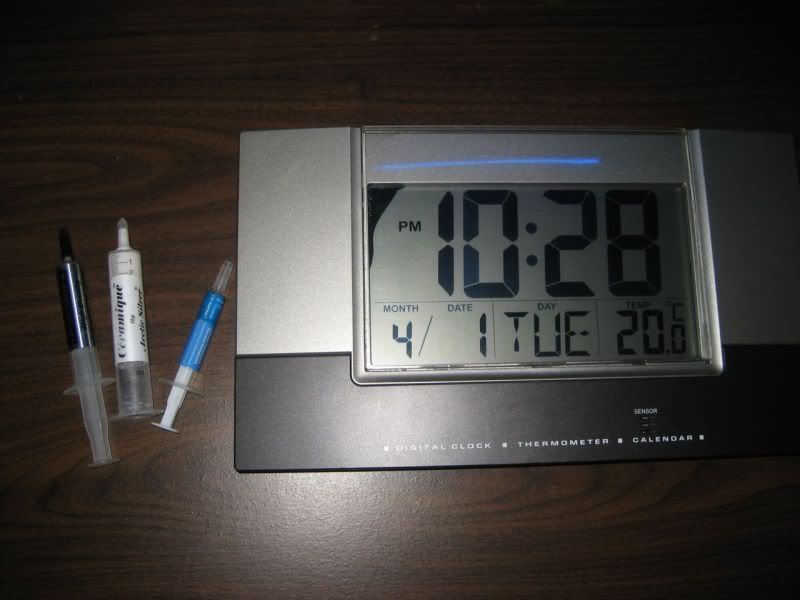

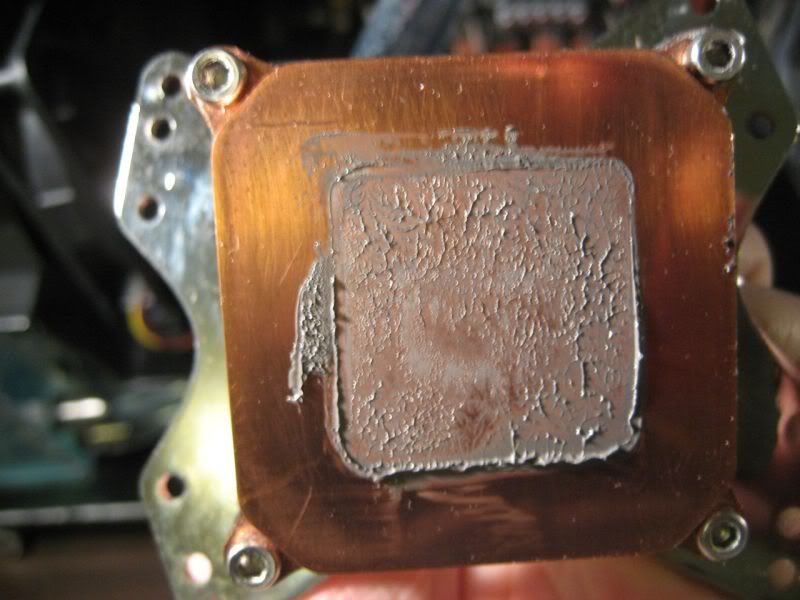

I'll add the best pieces of your report to my next report. I've been minimal with the pics....I like your approach here.

I'll add the best pieces of your report to my next report. I've been minimal with the pics....I like your approach here.

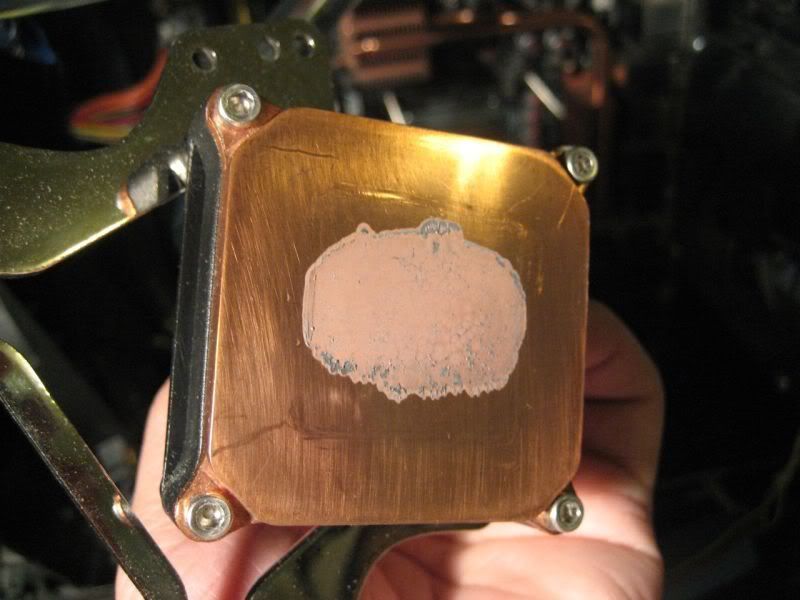

I am intrigued by the bacon grease part though, still.....) I'm up to testing different compositions too. I wonder if a bit thinner, no twist, would result in better transfer. The animal you're dealing with is not like metal or ceramic based TIMs. I find this entire exercise fascinating....and yes, if Innovative profits from it, just remember your friends here at XS/WCG......

I am intrigued by the bacon grease part though, still.....) I'm up to testing different compositions too. I wonder if a bit thinner, no twist, would result in better transfer. The animal you're dealing with is not like metal or ceramic based TIMs. I find this entire exercise fascinating....and yes, if Innovative profits from it, just remember your friends here at XS/WCG......

btw, all my mounts were horizontal.

btw, all my mounts were horizontal.

Bookmarks