Application

Every manufacturer has their own prescribed method of grease application for this test I would use our method out of the gate, then when you know what the best possible result that be gotten you have a basis to fine tune or experiment with your own application methods if you feel the need to do so. The magic Cross is the best application method I have seen to date but tends to use more paste.

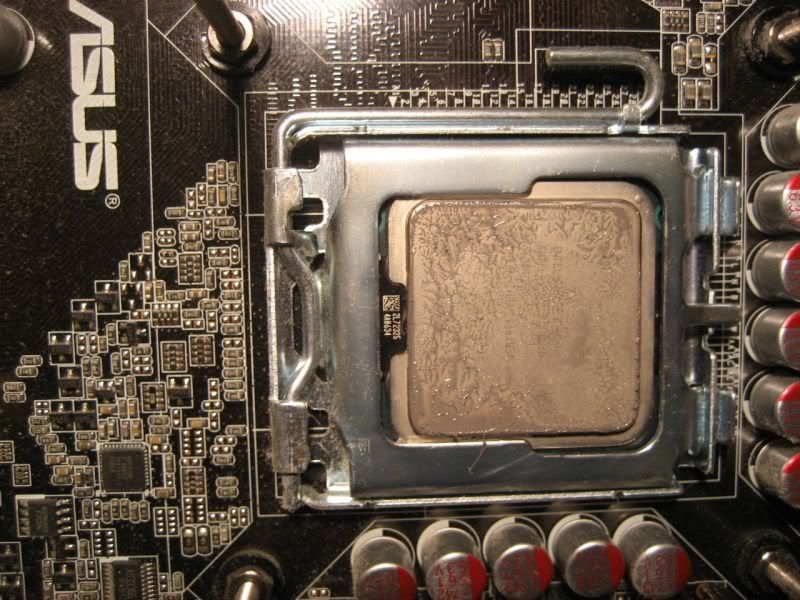

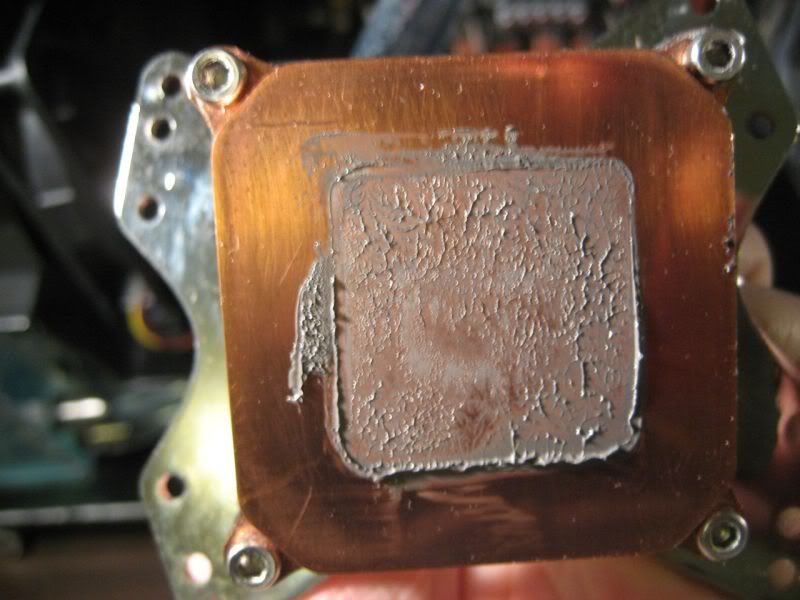

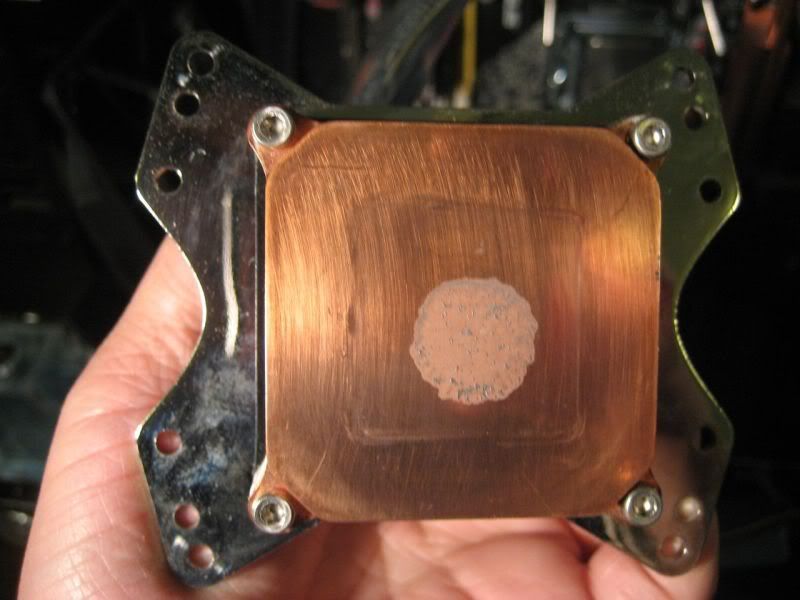

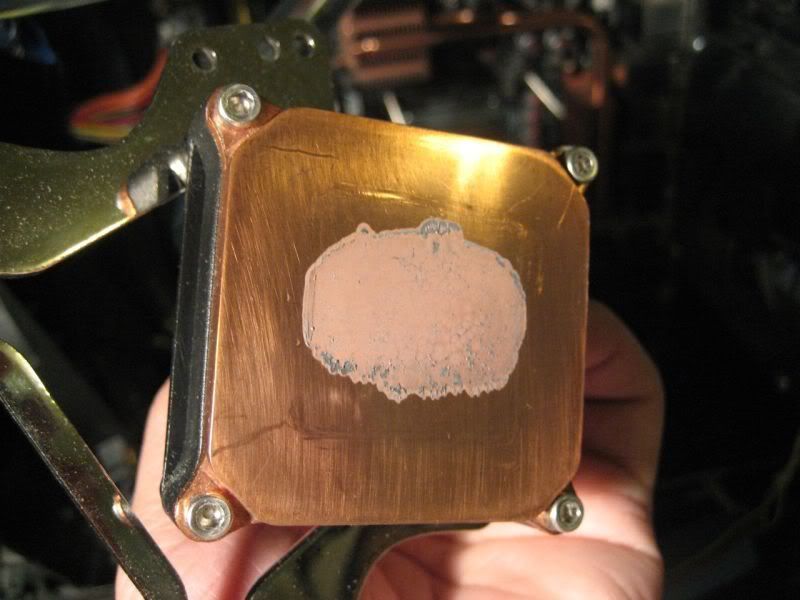

IC Diamond is composed mostly of diamond powder, and as such is quite thick. Proper application is critical to optimum performance. Squeeze onto the center of the CPU an amount of IC Diamond compound about the size of a pea - the center of the CPU is where most heat is concentrated. Place the heat sink on the CPU and press it down , then twist it back and forth a couple of times to spread IC Diamond over the CPU's surface. Clamp the heatsink and power up the PC.

We recommend a pea sized amount on center to increase the likelihood of optimum results for the average user. That amount with the proper pressure will spread to cover the entire area of contact between the sink and IHS 100% of the time. All paste application amounts are subject to a kind of artistic guesswork i.e a grain of rice is marginal with ICD7, it is highly bulk loaded for long term stability, very different than the "wet" style lightly loaded greases which are subject to bake out or pump out in the short term.

A squirt and squish with a twist to spread it around is just about as easy as it gets and from our experience effective and foolproof.

Mounting pressure

Watch or make note or just be aware of your mounting pressure, we have a chart on our site showing performance vs pressure. For example from 60psi to 45 psi thermal resistance doubles from an increase in Bond Line Thickness (BLT). Obviously I do not expect that measurement from the group but it is a performance issue that will affect results. Lightly loaded sinks will affect performance significantly and not just for ICD7 also on tests I have done on competitive greases

http://download.intel.com/design/Pen...s/30255304.pdf

Above Intel link has a discussion of heat sink pressure loads on an Intel stock solution sink. Some of the loads discussed pg 51 43 lbs. +/ 10lbs.

So referencing back to the ICD7 chart pressure vs thermal resistance Innovation Cooling

Good stuff to browse for key points. Intel says to cover the entire IHS with TIM. Designs should compensate for retention bracket fatigue. That the IHS gets flatter with more pressure, internal diodes stuff etc.

ICD7 Background Discussion

There are 2 primary considerations that are inextricably linked in TIM overall performance the two components are.

1.Bond Line thickness- The thinner the joint the less resistance to heat transfer

2. Bulk thermal conductivity- The fillers ability to conduct heat

So an ideal grease would comprise a very thin bond line coupled with a filler that has great ability to conduct heat like copper, aluminum, silver and in our case diamond. All formulations try to hit this perfect ideal with some combination of the two. Some lean more towards more bulk some lean more to low viscosity for a better BLT.

A number of the performance type pastes operate on what I call the peanut butter or toothpaste principle from user TIM experiments I am sure most of you have heard about at one time o r another. A "wetter" grease with less bulk and more liquid will spread and cover a larger area and give you a thin BLT but the thermal conductivity may be low, but the performance initially is pretty good. That kind of paste gets it's performance due to its relatively thin thickness, but it's performance is relatively short lived like the peanut butter. It dries or pumps out in a relatively short time frame.

To develop a better mousetrap compound the effort was focused on performance and longevity/reliability. Performance was the easy part, the reliability part while harder to execute could not be simpler in concept. It is harder to bake or pump out a solid than it is a liquid. The bulk loadings on ICD7 were pushed as high as we could go(94%) and still maintain some workability and resulted in a extremely stable long term mix

As it not reasonable to run multiple year-in system tests, we have run some accelerated tests that are indicators of reliability.

We ran a test ICD7 in a thermal cycling chamber - from -40 C to +85 C - for up to 250 cycles (with the copper block heated with 130 W of power) and found no change in thermal performance / thermal resistance of the grease

In a separate test we pulled "full vacuum" on ICD7 with a mechanical pump for ca. 65 hours at room temperature. The resulting ... weight loss was almost immeasurable - 0.3 mg out of 6.2222 g. This works out to me 0.0048 wt %.

Another test we ran ICD7 for 1000 hrs @125 C with no change in thermal performance.

I have one system where I have been running approximately 1.5 years with no change in thermal performance.

If people came to me 5 years from now and said that ICD7 was still working fine, I do not think I would be much surprised.

Requested Test Information

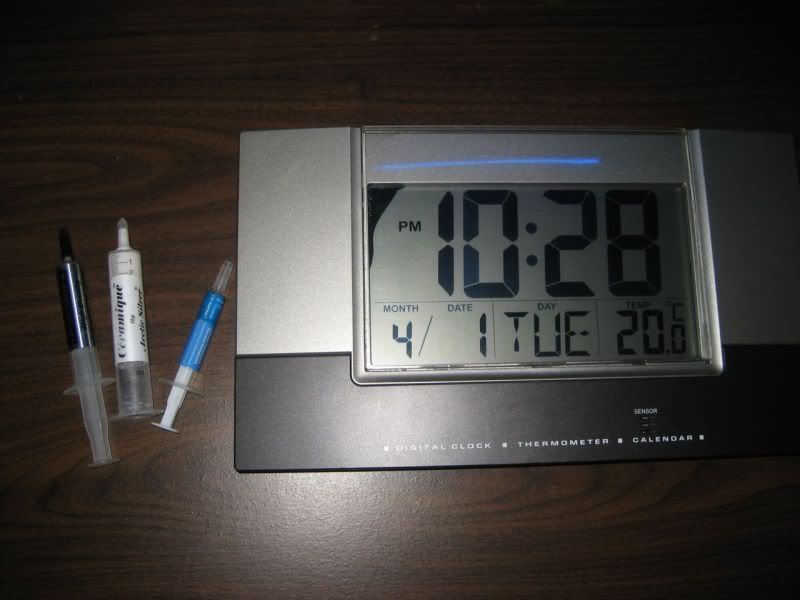

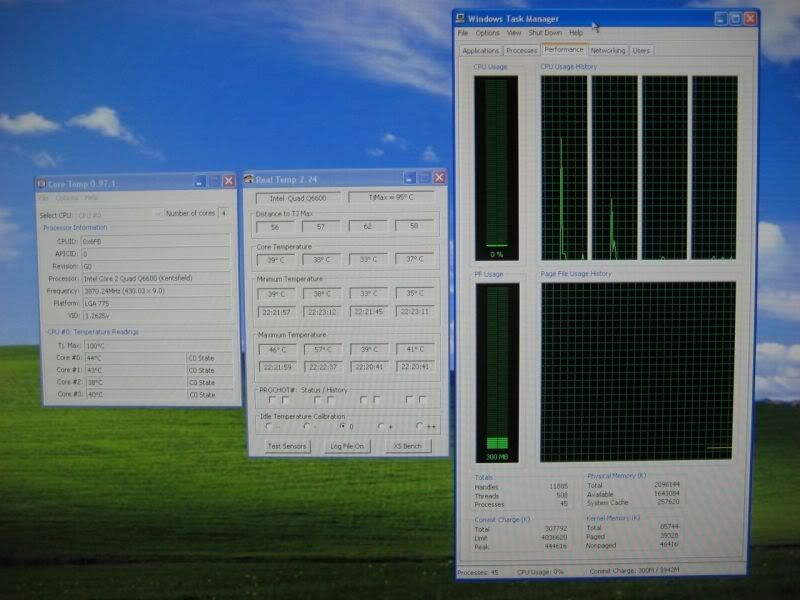

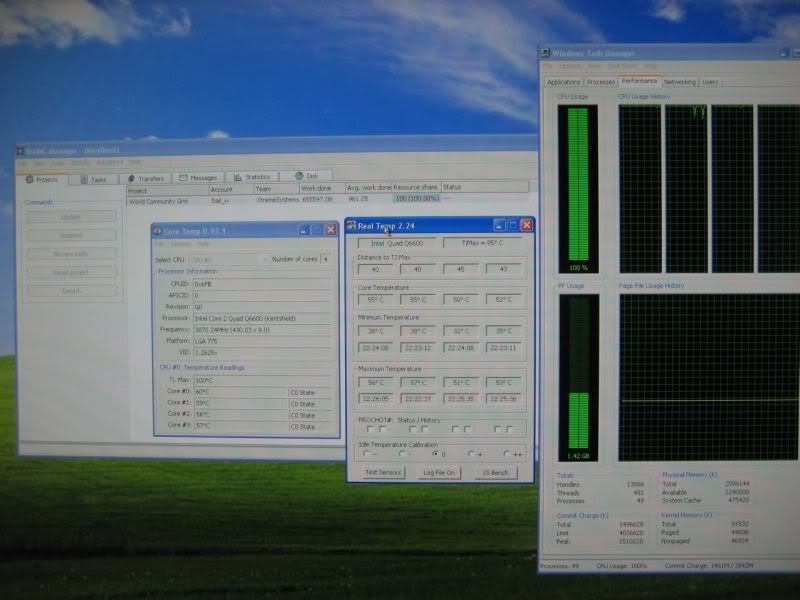

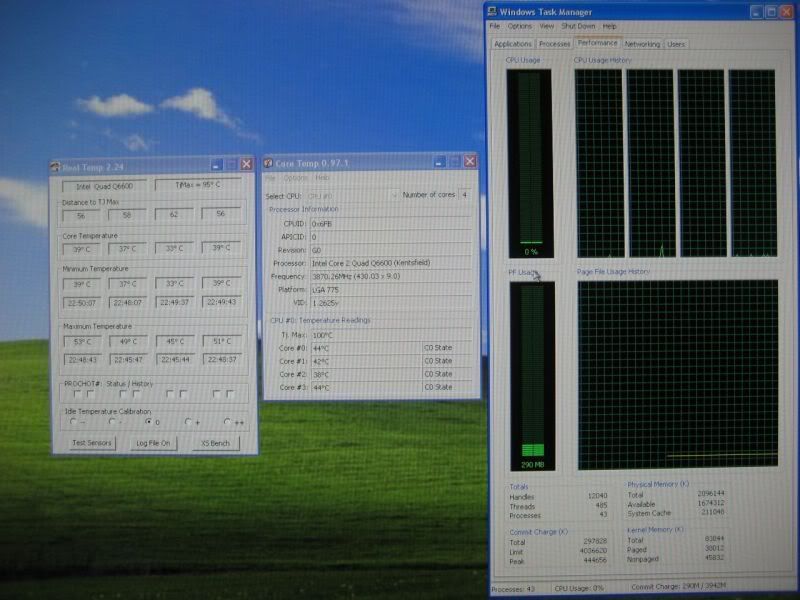

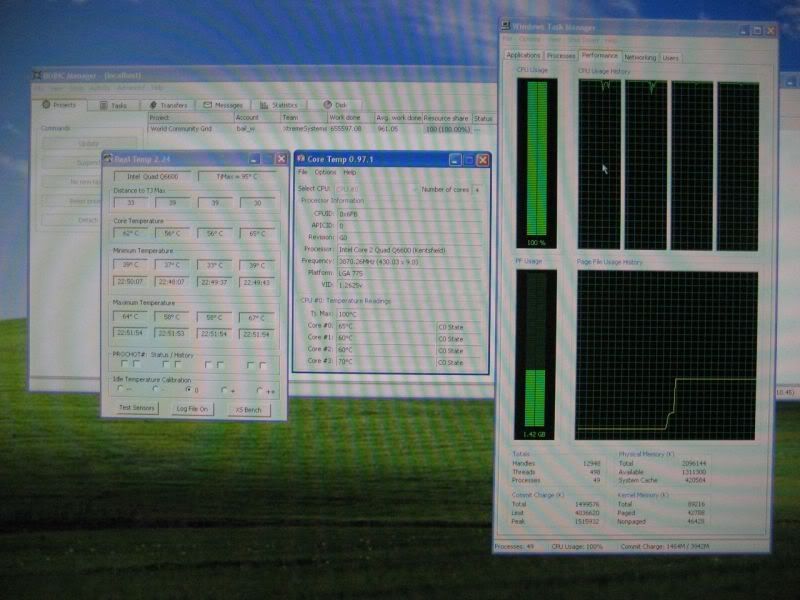

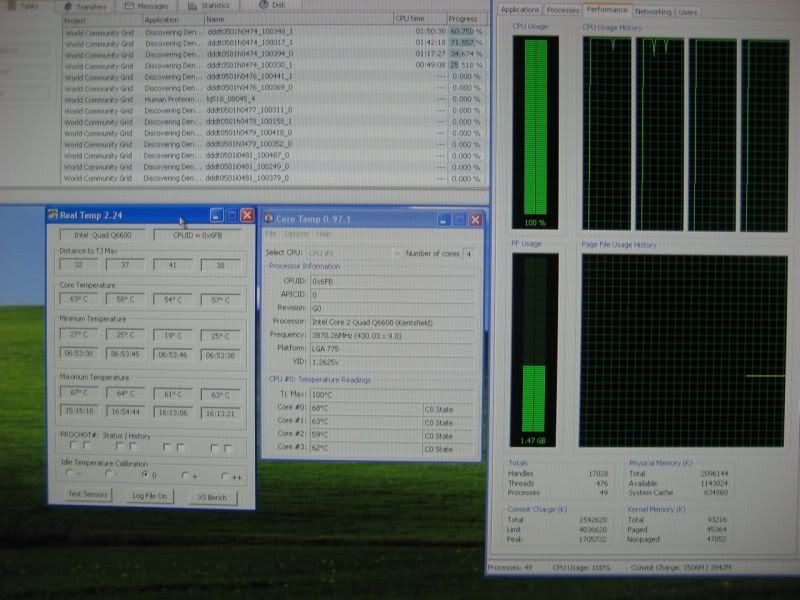

We would like the before load and idle temps along with the age or time in place of the previous mount

The ICD7 load and idle temperature and if possible some care on the ambient temperatures from both before and after readings.

Feel free to make any observations, comments or suggestions we ar trying to refine our message, application and problem trouble shooting so the information you supply to us is valuable to us and much appreciated

That's basically it you are pretty much on your own, whatever result you get is what it is. I may comment occasionally or suggest trouble shooting points but not much else. At the end of the exercise we will provide a chart of the results with links to the data for viewing and suggested corrections.

Thanks again all for your time and effort

Andrew

--

Innovation Cooling

350 East Main street

Ansonia CT. 06401

web site

http://www.innovationcooling.com/

I twisted and pushed the TRUE firmly into the board. It is mounted with the screws tightened all the way, as before.

Reply With Quote

Reply With Quote

Ever go through 6 month old thread. and guys say,,, 'Ya so same rig as in my sig I put the 3800 X2 into ' . The you look at sig and he's got Q6600 + Asus Preium etc etc.

Ever go through 6 month old thread. and guys say,,, 'Ya so same rig as in my sig I put the 3800 X2 into ' . The you look at sig and he's got Q6600 + Asus Preium etc etc.

It is best described as a mix between mineral oil, bacon grease, and dirt, with a healthy hint of peanut butter in the background. It wasn't as bad as I thought it would be. I've gotten old axle grease in my mouth, from working on cars, that was much worse.....

It is best described as a mix between mineral oil, bacon grease, and dirt, with a healthy hint of peanut butter in the background. It wasn't as bad as I thought it would be. I've gotten old axle grease in my mouth, from working on cars, that was much worse.....

my wife's system now!

my wife's system now!  I Feel really Good now!

I Feel really Good now!

btw, all my mounts were horizontal.

btw, all my mounts were horizontal.

Bookmarks